Drilling rod connector with inner spraying and drilling fluid leaking preventing function

A drill pipe joint and ball head technology, which is applied to drill pipes, drilling equipment, drill pipes, etc., can solve the problems of short service life, loss of drilling fluid, and great harm, and achieve convenient operation, prevent leakage of drilling fluid, and avoid internal problems. spray dangerous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

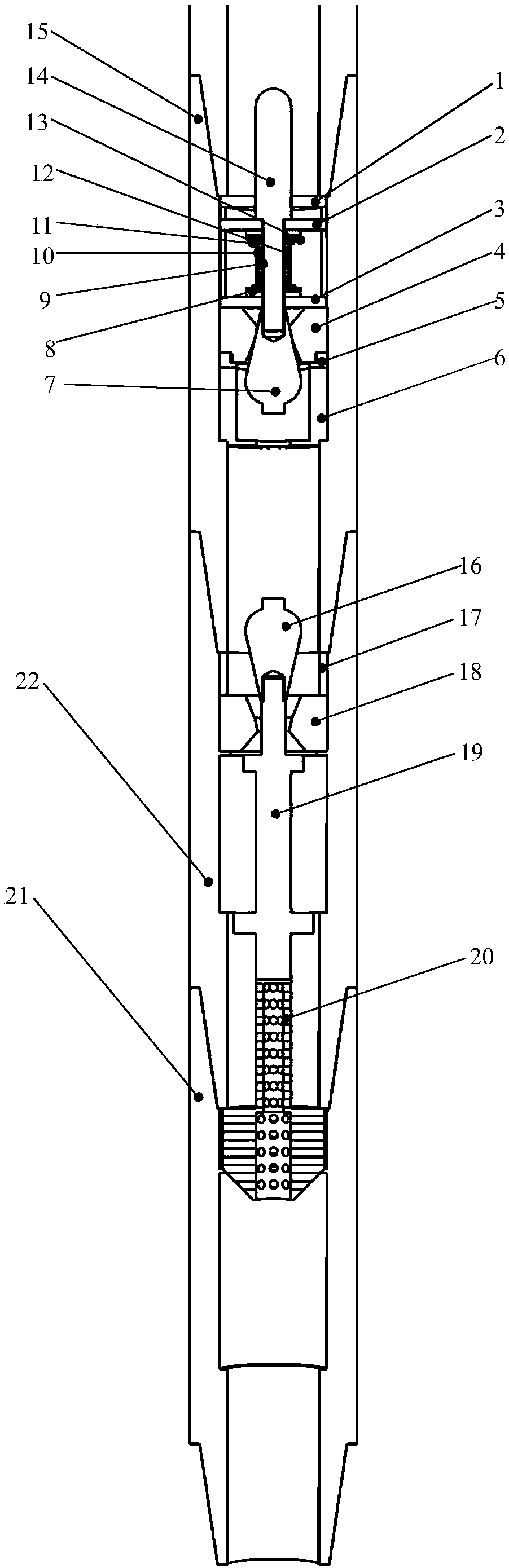

[0049] The present invention will be further described below in conjunction with accompanying drawing:

[0050] The present invention can achieve the following purposes: when drilling into a high-pressure formation during drilling, the blowout prevention structure design of the special joint can quickly and automatically close the overflow area to prevent the drilling fluid from blowing out; when the drilling platform is connected to a single , the pump pressure is reduced to zero, and the annular flow channel is automatically closed through the automatic reset function of the sealing structure, and the upper hydrostatic pressure is offset by the spring preload, so as to prevent the loss of drilling fluid when a single connection is made. It fills up the domestic gap in the design of the drill pipe structure for preventing the drilling fluid from blowing out during the drilling process.

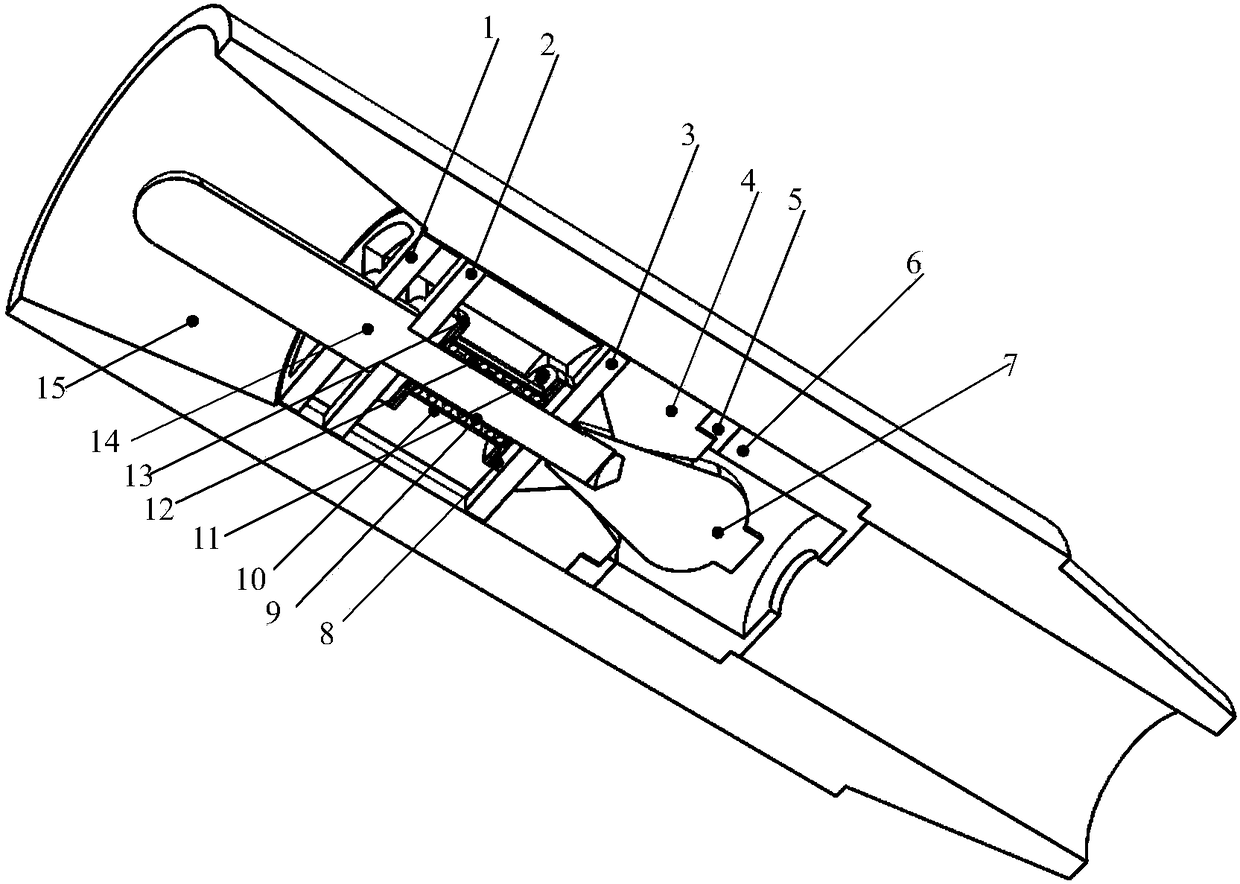

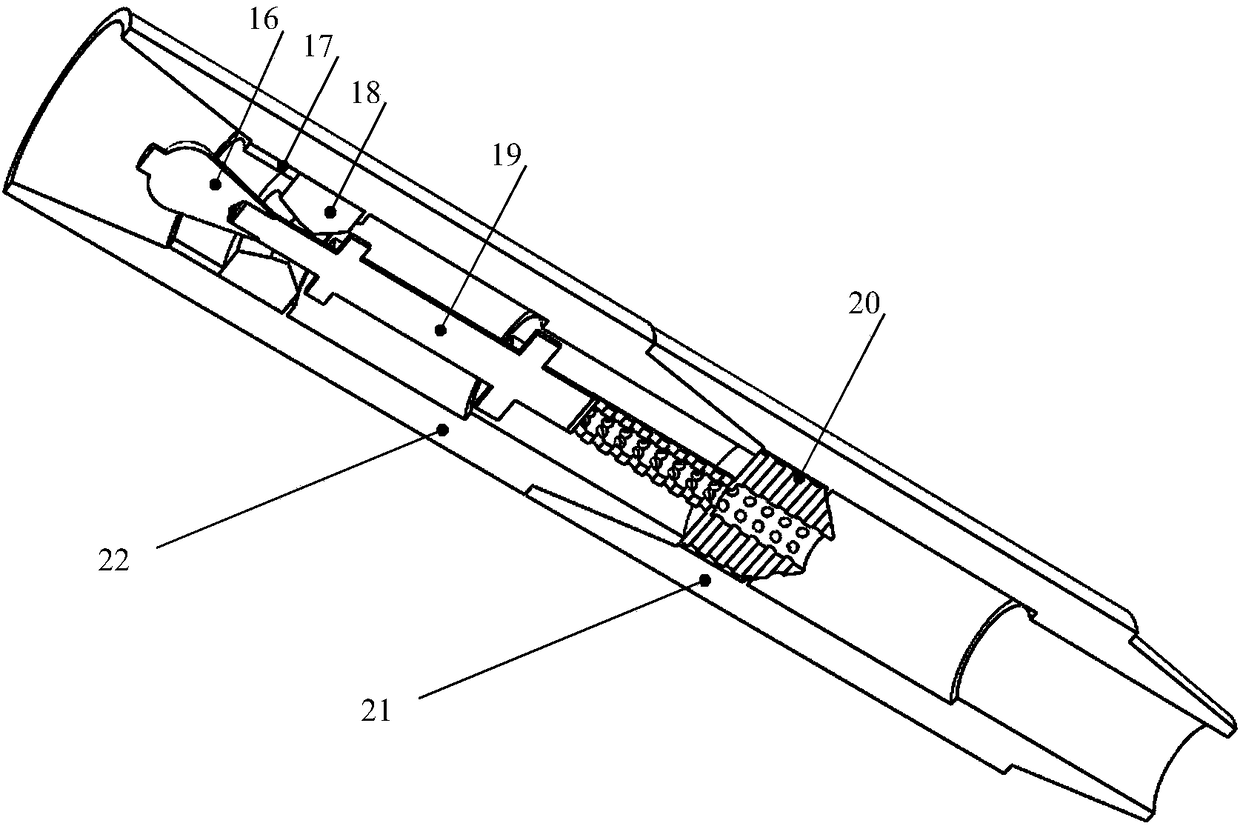

[0051] Such as figure 1 to combine figure 2 As shown, the main seal structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com