Middle-sized wind power generator maintenance tower

A technology for wind power generators and maintenance towers, which is applied in the direction of wind power generators, wind power generation, engines, etc., and can solve problems such as malfunction, poor adaptability, and poor stability of oil wire cables, etc., so as to improve the reliability of use and adaptability , Improve the effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

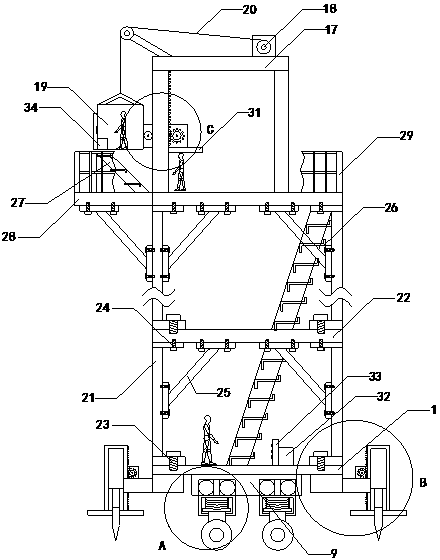

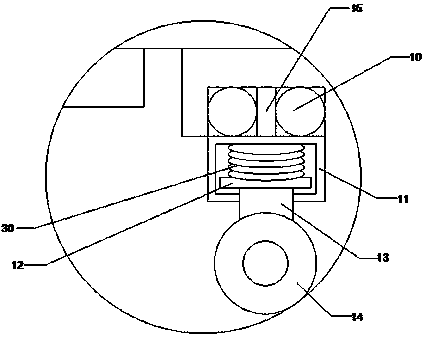

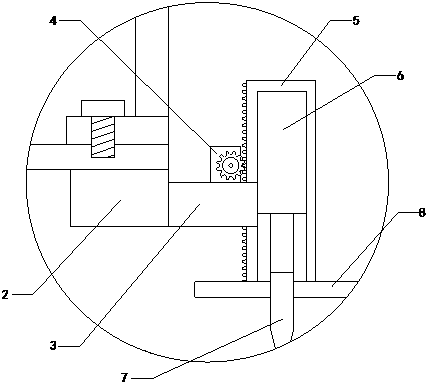

[0020] Such as Figure 1 to Figure 5As shown, a medium-sized wind power generator maintenance tower of the present invention includes a base plate 1, a connecting plate group 2, a connecting sliding sleeve group 3, a gear motor group 4, a hydraulic cylinder sleeve group 5, a hydraulic cylinder group 6, and a fixed anchor group 7 , foot plate group 8, platform plate 9, ball bearing group 10, sleeve group 11, limit shaft group 12, strut group 13, roller group 14 and support platform, the connecting plate group is respectively located at the left front side of the bottom end of the bottom plate, Left rear side, right front side and right rear side, and the top of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com