Automobile and locomotive combined transmission suitable for electric power pushing

A technology for transmissions and automobiles, applied in mechanical equipment, transmissions, belts/chains/gears, etc., can solve problems such as unsuitable transmissions, and achieve good effects of increased torque, variable speed, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

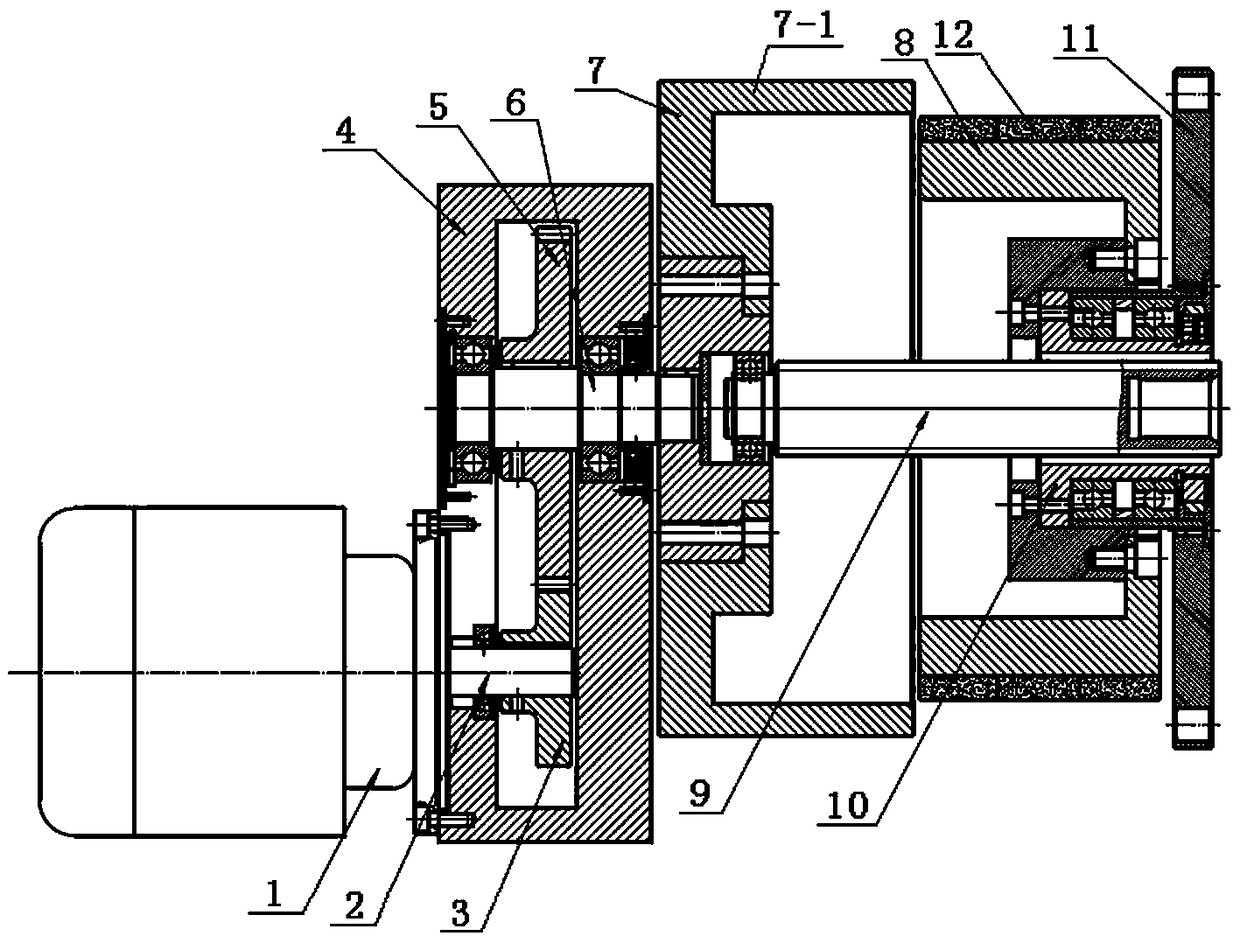

[0027] see figure 1 , present embodiment 1 is suitable for the combined transmission of automobiles and locomotives driven by electric power, including a bracket 4 supporting the output shaft 2 of the motor 1, a driving gear 3 mounted on the output shaft of the motor in the bracket, and the axis of the bracket is parallel to the axis of the output shaft of the motor The rear end stretches out the active magnetic induction body shaft 6 outside the bracket, the driven gear 5 which is mounted on the active magnetic induction body shaft in the bracket and meshes with the driving gear, and has a layer of magnetic induction coil mounted on the active magnetic induction body shaft 7-1 The active magnetic induction body 7, the first end coaxial with the axis of the active magnetic induction body is supported in the active magnetic induction body and the second end is supported on the dial 11 driven by the servo motor (or hydraulic pressure) The driven permanent magnet coil shaft 9, th...

Embodiment 2

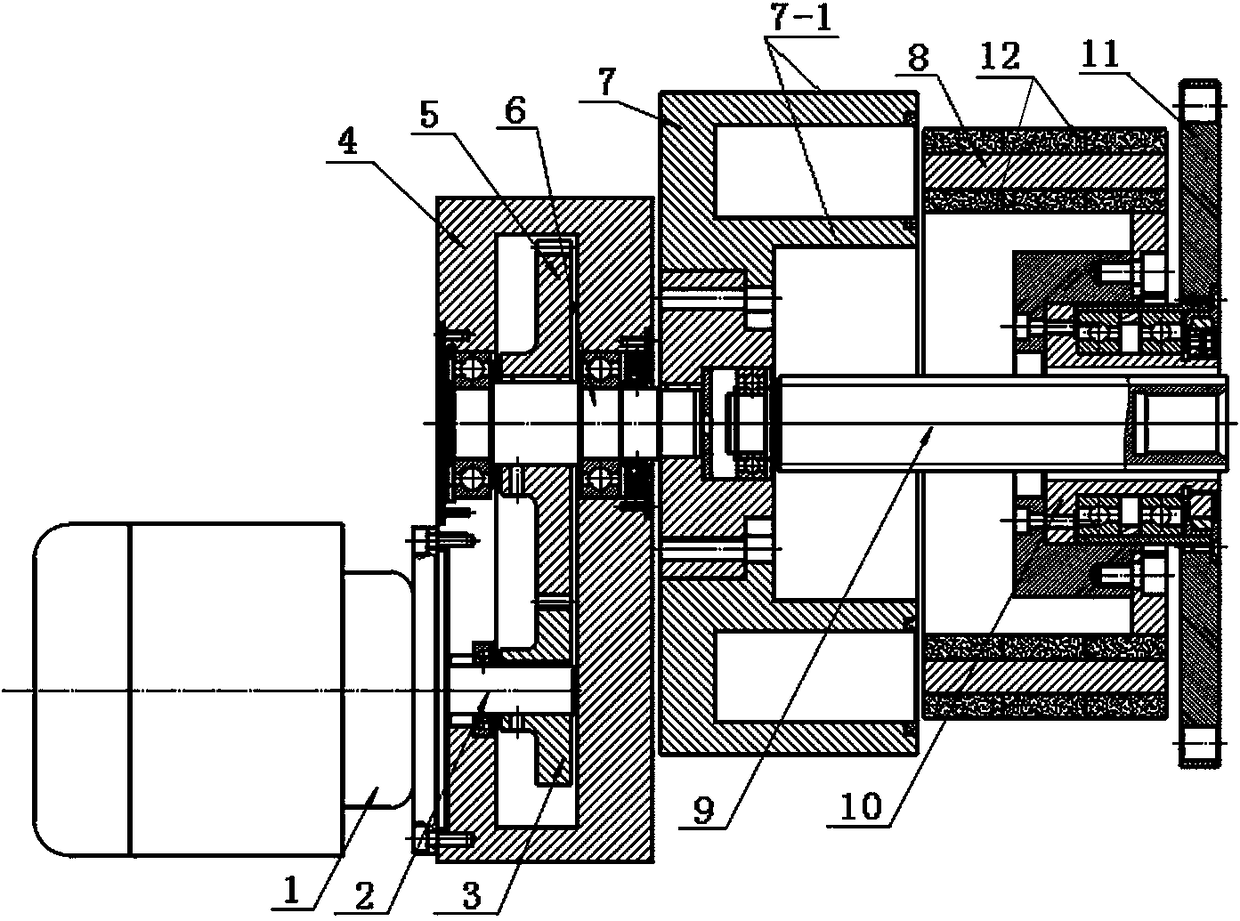

[0037] see figure 2 , present embodiment 2 is basically the same as embodiment 1, and the difference is that the gear ratio of the driving gear and the driven gear is 1:2.5, the magnetic induction coil on the active magnetic induction body is two layers, and the inner and outer rings of the driven permanent magnetic coil Permanent magnets 12 are all housed on the outer walls. The transmission realizes a small body position and a large torsion energy. It adopts Changan Yidong EV, pure electric vehicle, permanent magnet synchronous motor, maximum power of 90KW, maximum torque of 280NM, vehicle weight of 1610Kg, cruising range of 200Km, and maximum speed of 140Km per hour.

[0038] With this transmission scheme:

[0039]For the design of fuel vehicles, as long as the quality of the vehicle, the required power, the torque required for starting (hill start), sufficient traction and top speed can be matched, the corresponding power and transmission can be matched. The tonnage st...

Embodiment 3

[0046] see figure 2 , the present embodiment 3 is basically the same as embodiment 2, the difference is that the gear ratio of the driving gear and the driven gear is 1:2.5, and the heavy-duty truck is calculated with this transmission.

[0047] The fuel heavy truck is 290, with a total loading mass of 14 tons. Currently installed is a 290 hp diesel engine. Equivalent to 217KW. Torque of 420NM.

[0048] A 115KW permanent magnet motor is used, with a peak torque of 850NM, a speed of 2500-4500 and this transmission (the transmission is equipped with a fixed permanent magnet brake ring) to form a truck transmission. Gear ratio 1:2.5, fork speed 1:3.7. The diameter of the tire is 1.10m. The calculation is as follows: the car is changed to electricity. Calculated according to the motor parameters and the design parameters of the transmission, the modified truck torque is 2125NM. It is 1.37 times the torque of the first gear of the fuel vehicle, and the load is 2125÷130=16.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com