Hybrid system

A hybrid system and meshing technology, applied in hybrid vehicles, power units, electric power units, etc., can solve the problems of difficult sealing, high motor cost, and complicated restrictions on the degree of freedom of dual motors, and improve the life of seals. , The effect of reducing fuel consumption and increasing the probability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment,

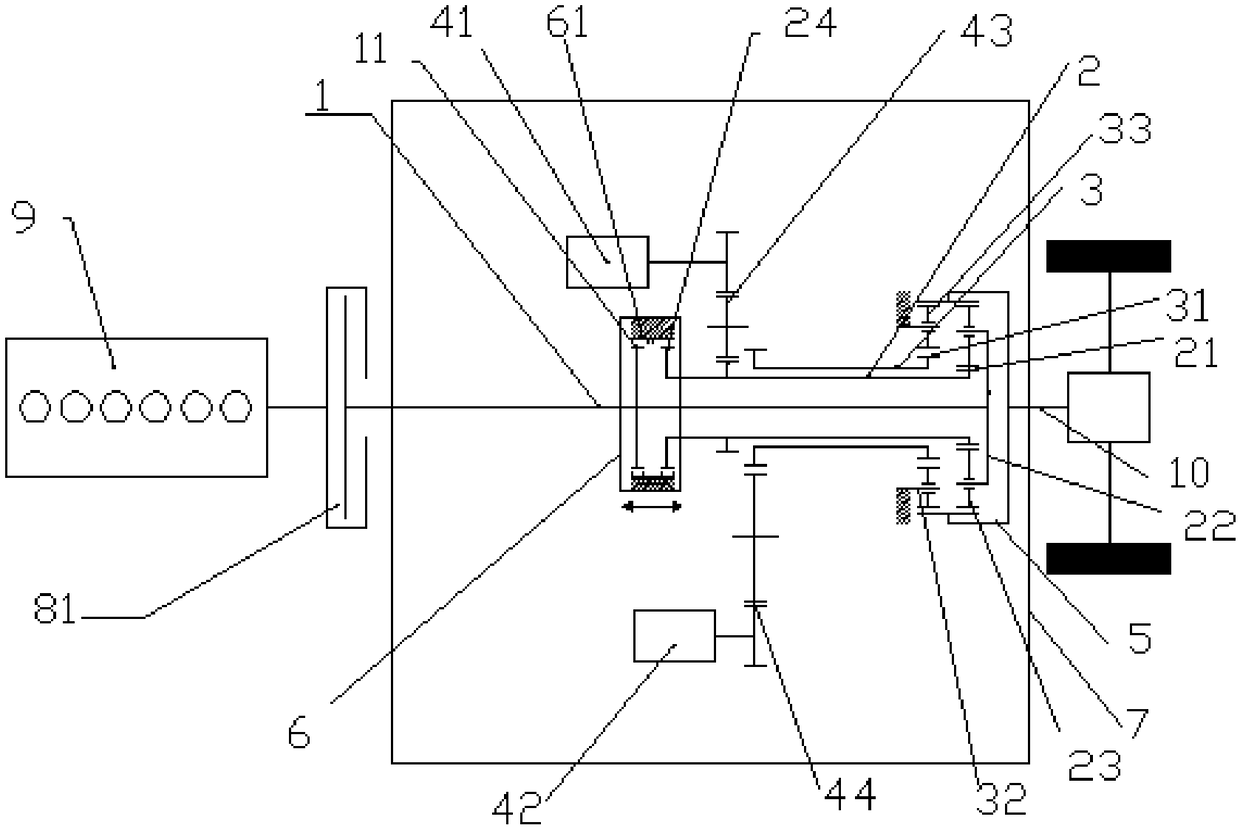

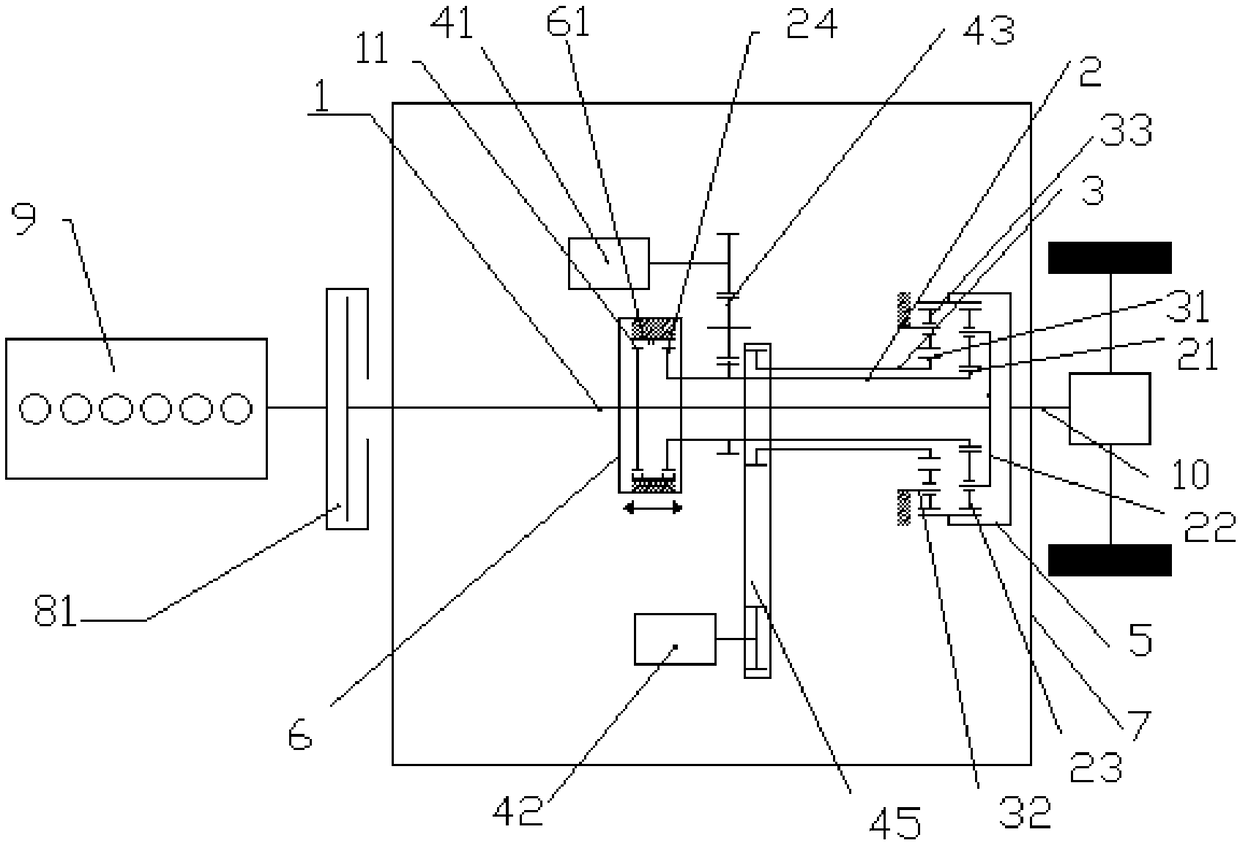

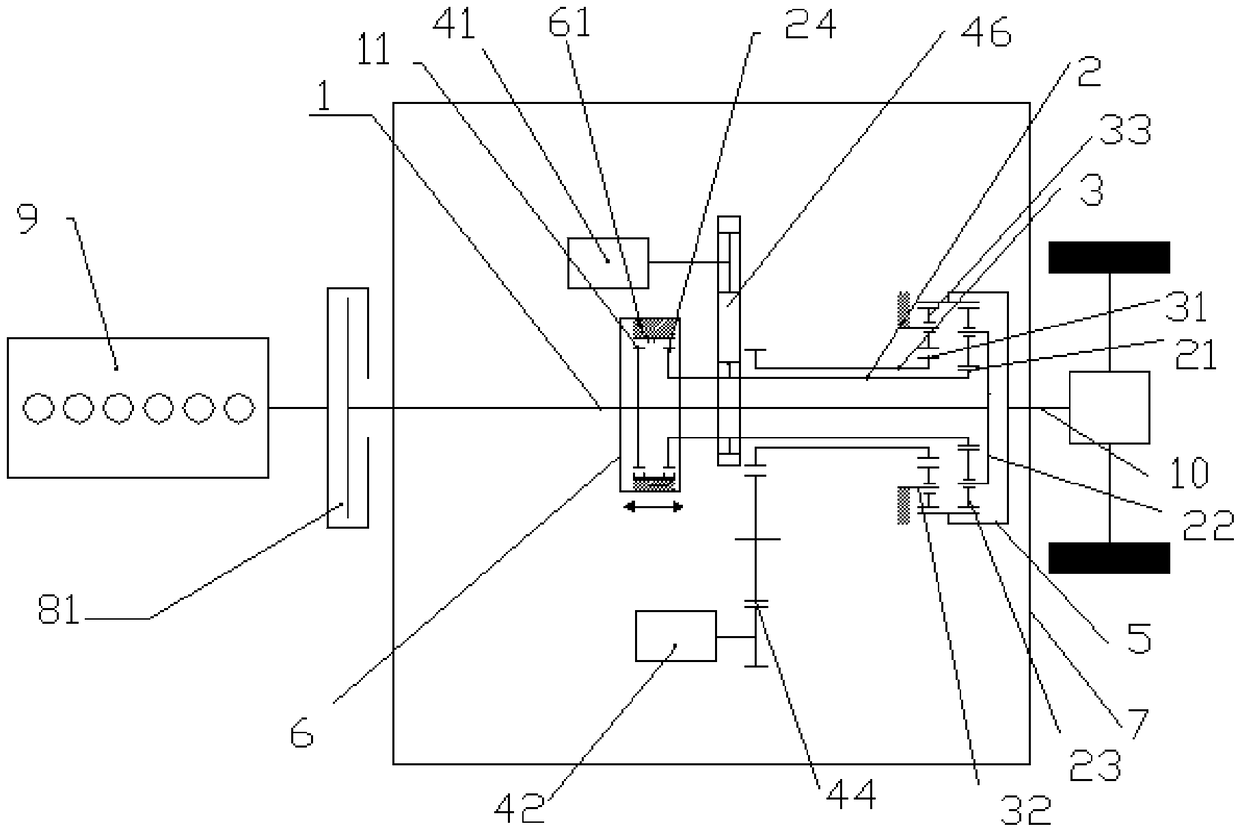

[0030] Such as figure 1 Shown: a dual-motor dual-planetary hybrid system with two-way brakes 6 triaxial coaxial, including:

[0031] A central shaft 1, one end of the central shaft 1 is provided with a rear planetary carrier 22, the rear planetary carrier 22 is provided with a rear planetary wheel 23, and the other end of the central shaft 1 is connected to the output end of the engine 9;

[0032] The first hollow shaft 2, the first hollow shaft 2 is sleeved on the central shaft 1, the rear end of the first hollow shaft 2 is provided with a rear sun gear 21, and the rear sun gear 21 is connected to the Rear row planetary gear 23 meshes;

[0033] The second hollow shaft 3, the second hollow shaft 3 is sleeved on the first hollow shaft 2, the rear end of the second hollow shaft 3 is fixedly provided with a front row planet carrier 32, and the front r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com