A method for detecting oil leakage rate

A process method and oil leakage technology, applied in the direction of detecting the appearance of fluid at the leak point, measuring device, fluid tightness test, etc. Problems such as sealing faults of tiny leaks are detected to achieve the effect of wide application potential, improved detection accuracy, and damage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the public implementation manners of the present invention in detail with reference to the accompanying drawings.

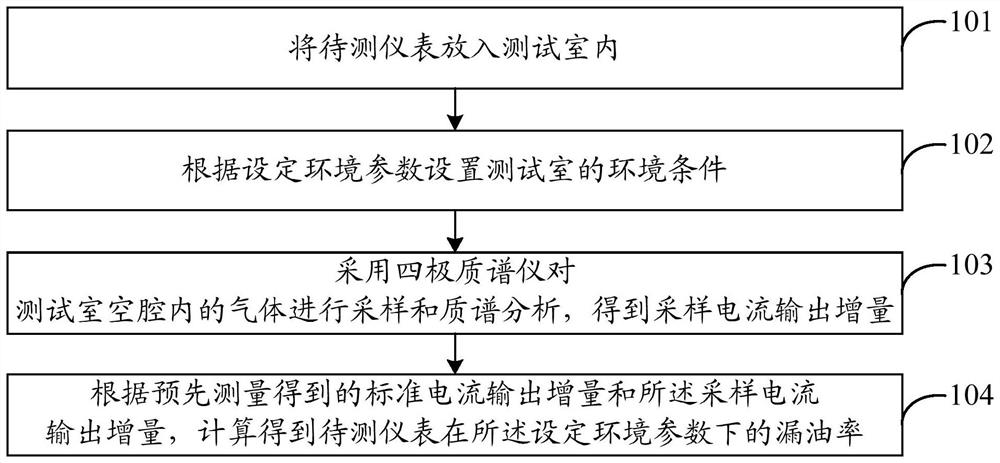

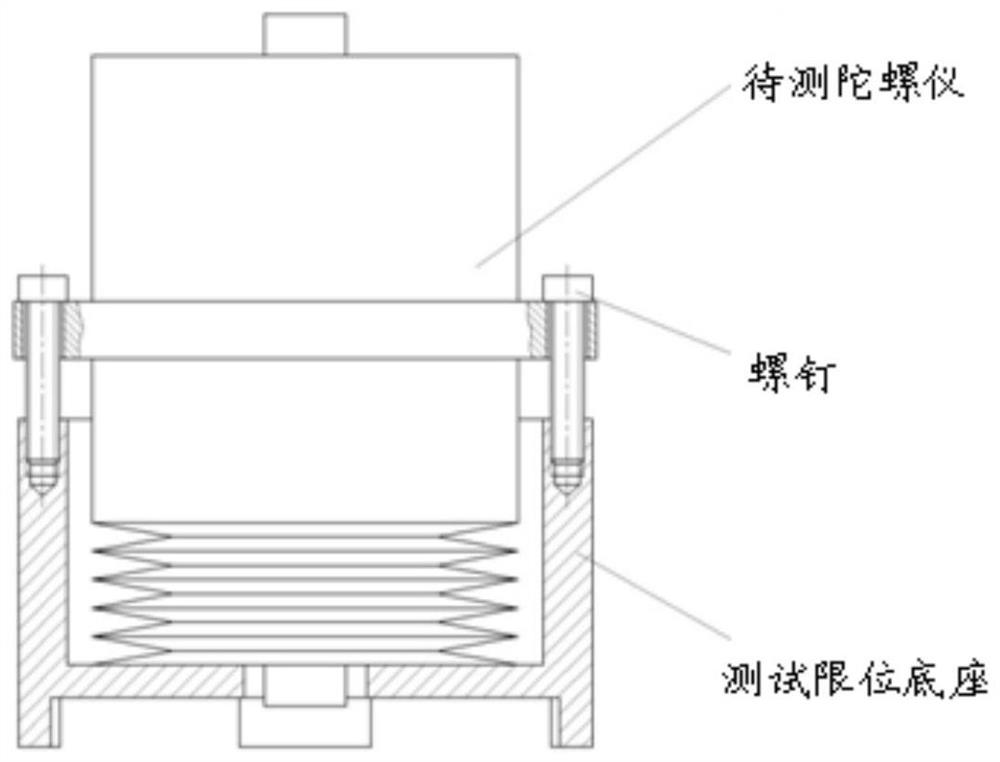

[0049] The present invention aims at the problem of low detection accuracy of the existing leak detection method by weighing the entire meter, and the problem that the detection state of the helium mass spectrometry leak detection method is inconsistent with the working state, and proposes a high-precision detection process method for the oil leakage rate of the entire meter. The method utilizes The instrument slick oil is volatile and can be sensitive by the quadrupole mass spectrometer. Combined with the high sensitivity of the quadrupole mass spectrometer, the standard oil volume filling method combined with the process method is used to achieve fast and high-precision calibration. The bellows structure will elongate when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com