A Design Method of Spiral Grounding Electrode with the Function of Reducing Resistance

A design method and technology for grounding electrodes, applied in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve the problem of inability to truly solve the influence of the distance between the topography and geomorphology, so as to shorten the distance between the electrodes and reduce the construction cost Cost, effect of reducing grounding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0053] (1) Design method of spiral ground electrode structure parameters

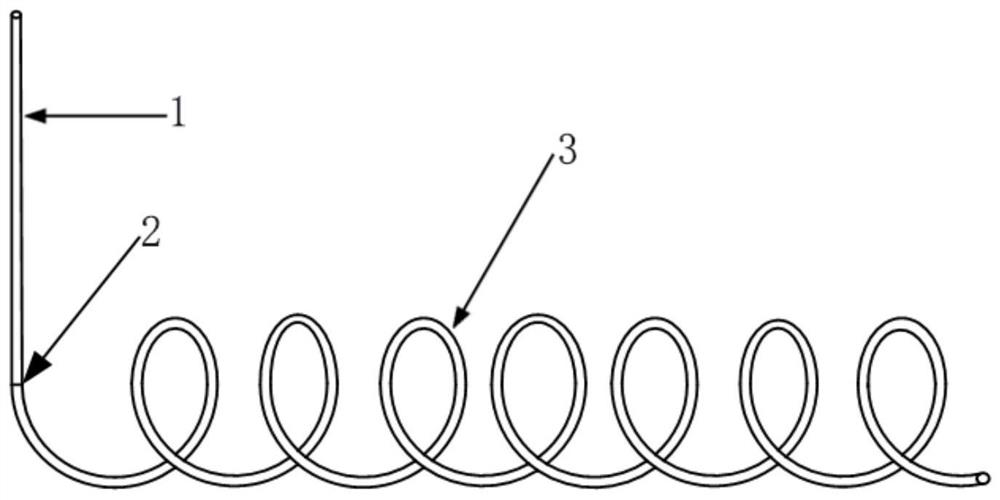

[0054] Such as figure 1 As shown, on the premise that the laying length of the original grounding electrode remains unchanged, the grounding electrode laid in a horizontal straight line shape is changed into a spiral shape, so that the laying length of the spiral grounding electrode 3 is the same as that of the original linear grounding electrode; Line 1 is connected to the spiral ground electrode at 180°, and the connection point 2 at this connection is the tangent point between the down conductor and the spiral ground electrode.

[0055] 1) Design of the length of the spiral ground electrode

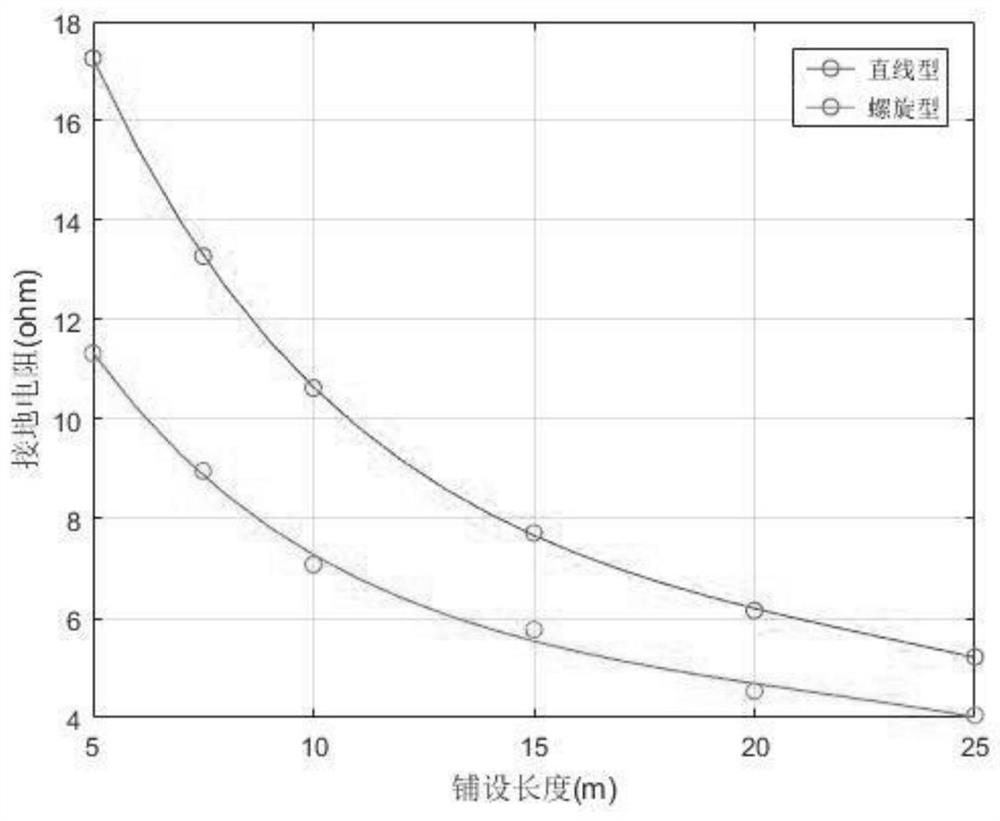

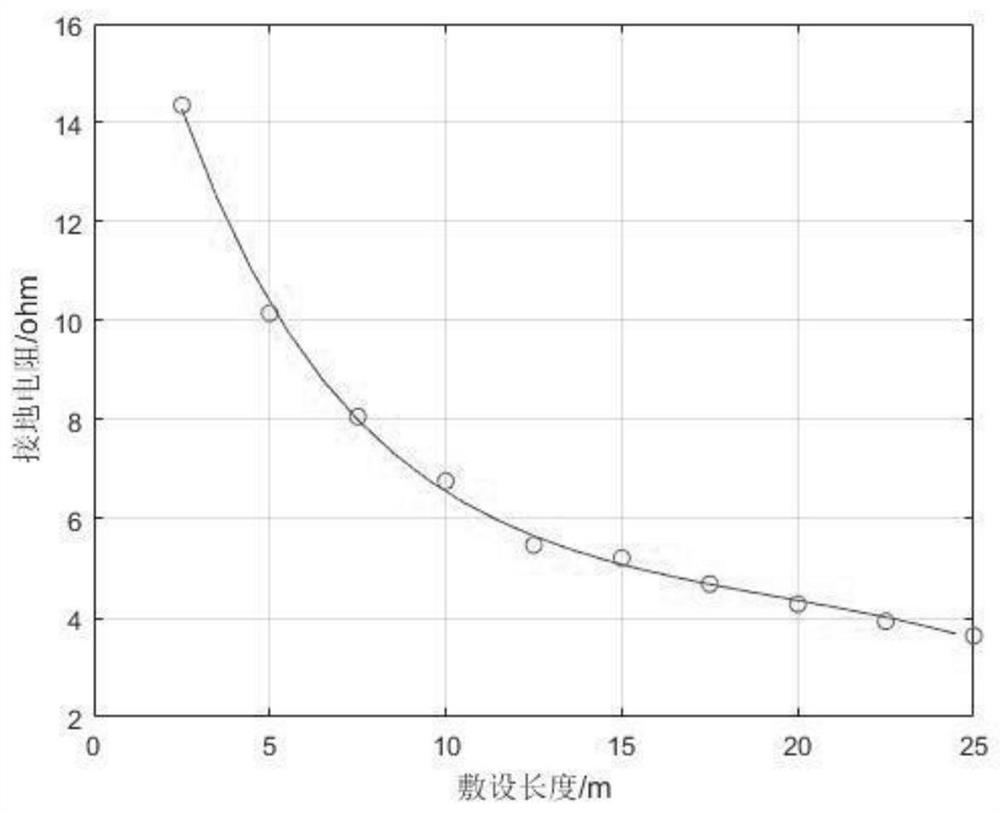

[0056] In order to obtain the design method of the spiral ground electrode with the best resistance-reducing performance of the spiral ground electrode, the calculation met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com