Non-constant current electric driving LED light-emitting device for plant lighting

A light-emitting device and plant lighting technology, applied in the field of plant lighting, can solve problems such as long cycle time, slow strobe irradiation, and stimulation of plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

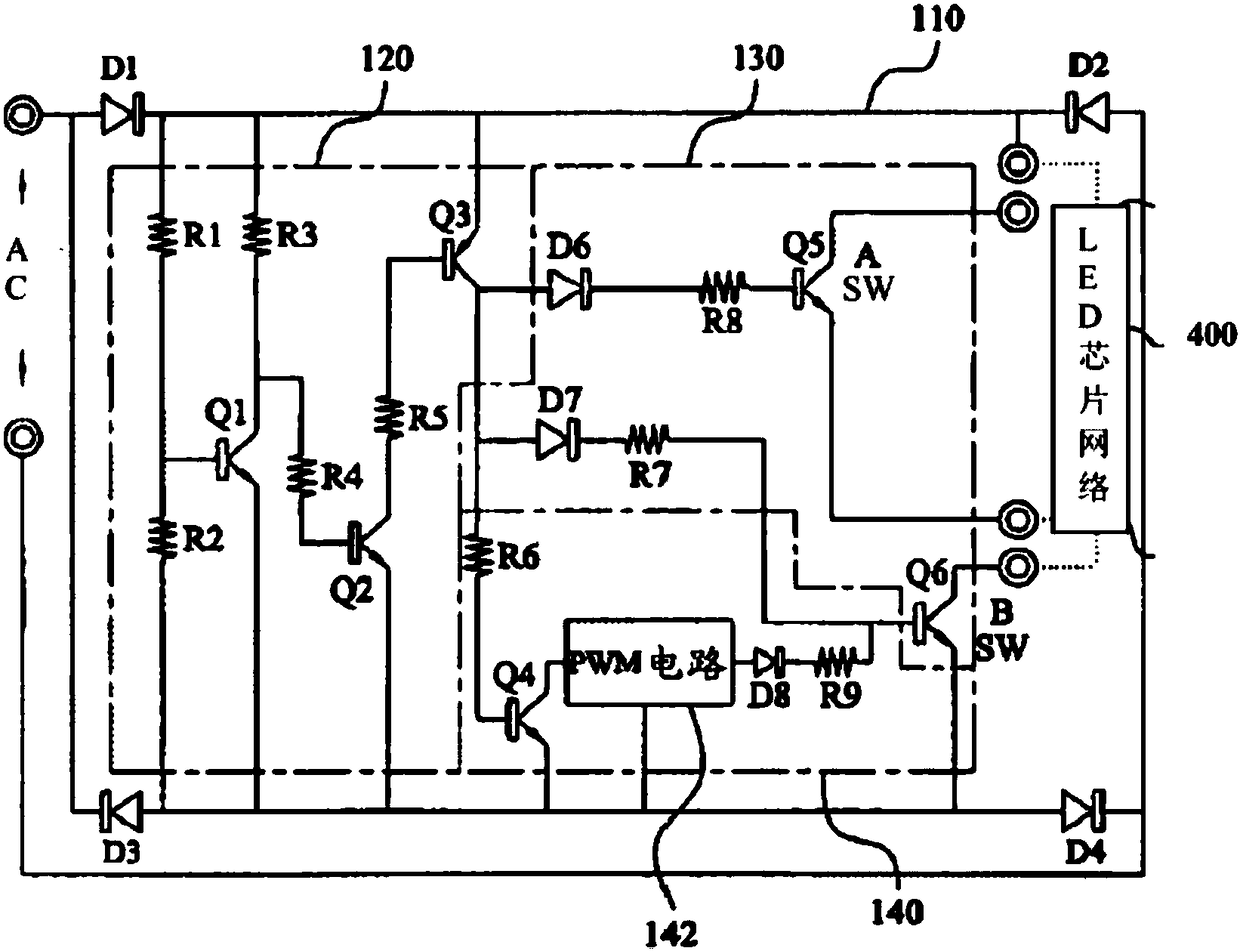

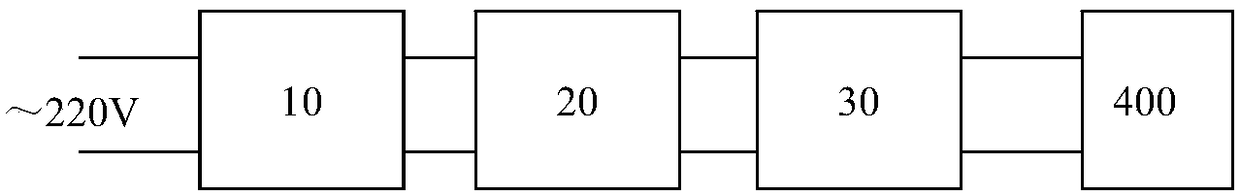

[0043] figure 1 and figure 2 The basic structural parts of the LED lighting device of the present invention are shown. Such as figure 1 As shown, the circuit part connected to the LED lighting device includes a filter circuit 10 , a current limiting circuit 20 , a current control circuit 30 and an LED chip network 400 . The filter circuit 10 , the current limiting circuit 20 , the current control circuit 30 and the LED chip network 400 are serially connected in series, thereby eliminating radio interference and providing security for the LED chip network.

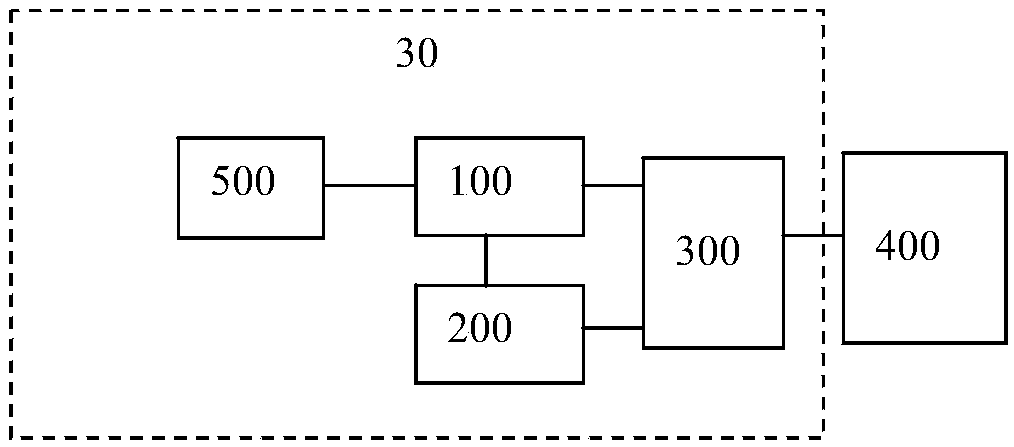

[0044]Preferably, the current control circuit 30 is used to control and divide the current, and control the current in the pulse period to be a non-constant current that changes according to a certain rule in at least two light-emitting stages. The current control circuit 30 at least includes a light engine module 300 . The light engine module 300 cuts the pulse current into two currents varying according to time in on...

Embodiment 2

[0059] This embodiment is a further improvement on Embodiment 1, and repeated content will not be repeated here.

[0060] Preferably, the preset pulse period lighting parameters of the present invention can be stored in the light engine module, or can be stored in the database 500 connected to the analysis module 100 . The database may be a database set in the current control circuit 30, or a third-party database. Preferably, the database is a cloud database.

[0061] Preferably, the analysis module 100 sends a matching request to the database 500 based on the plant parameters collected by the plant parameter collection module 200 to match at least one set of pulse period luminescence parameters corresponding to the plant parameters. Preferably, the database 500 stores pulse period lighting parameters for various growth stages of various plants. The analysis module 100 matches one set, two sets, three sets or even more pulse period lighting parameters from the database. Pre...

Embodiment 3

[0072] This embodiment is a further improvement on Embodiment 1 or Embodiment 2 and their combination, and the repeated content will not be repeated.

[0073] This embodiment describes the LED chips in the LED chip network in detail. The LED chip network includes at least blue, violet and / or ultraviolet LED chips coated with a luminescent coating. The luminescent coating includes a blue luminescent coating, a yellow luminescent coating and / or a red luminescent coating.

[0074] Preferably, the emission wavelength of the blue LED chip is 460 nanometers. The emission wavelength of the violet LED chip is 400nm. The emission wavelength of the ultraviolet LED chip is 254-365nm.

[0075] The LED light-emitting device formed by LED chips is composed of blue light, purple light or ultraviolet LED chips and blue light-emitting materials, green light-emitting materials, yellow light-emitting materials and / or red light-emitting materials. Wherein, the luminescent range of the yellow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com