A gun head device that is convenient for distance measurement and a method for controlling the height of the print head

A technology of print head and control system, applied in the field of electrofusion additive manufacturing, can solve the problems of influence distance, influence of workpiece performance, influence of workpiece performance, etc., to achieve the effect of improving accuracy and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

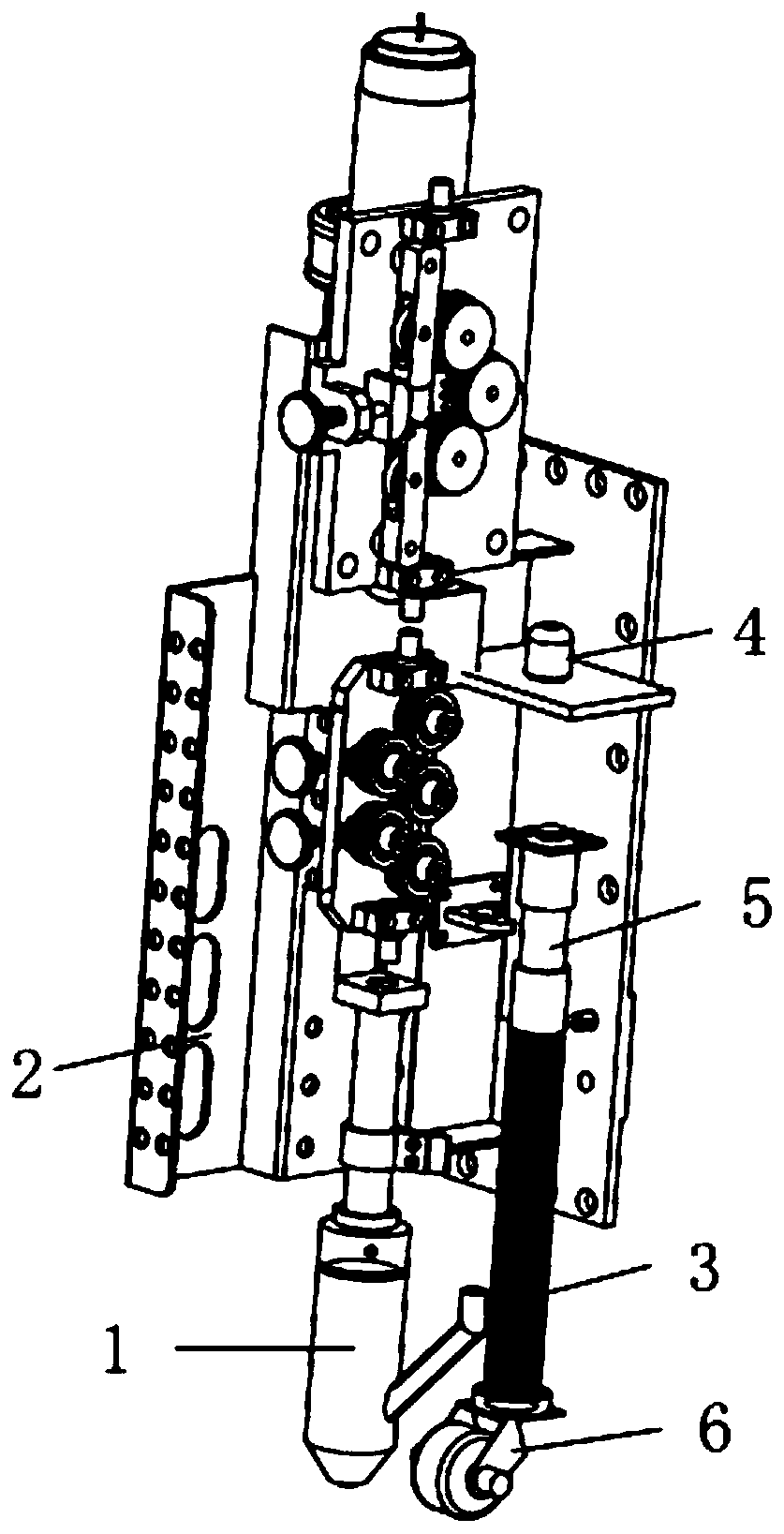

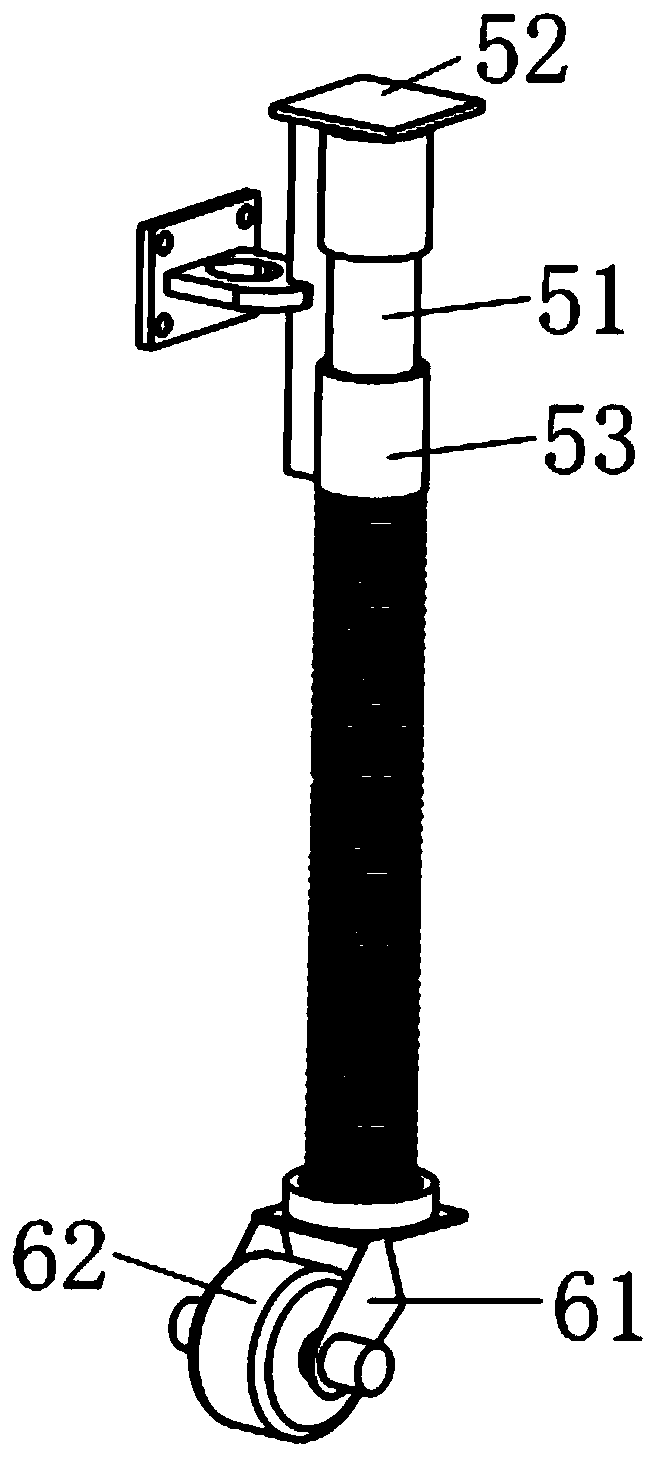

[0027] See attached figure 1 And attached figure 2 , the invention discloses a gun head device that is convenient for distance measurement, including a print head 1, a distance measurement mechanism, and a gun frame 2 for installing the print head 1 and the distance measurement mechanism. The distance detection assembly 4 on the 2 and the connecting rod group 5 installed under the distance detection assembly 4 can be lifted and lowered. The lower end of the connecting rod group 5 is equipped with a caster 6 relatively fixed in the axial direction, and the caster 6 is connected with the workpiece to be measured. The surface is always in a tight state. Wherein, the distance detecting component 4 is preferably an infrared distance measuring sensor. The present invention can also use other distance detection sensors, such as radar ranging sensors and the like. Wherein, the caster 6 is always in close contact with the surface of the workpiece to be measured through the downward...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that the connecting rod group in this embodiment is guided by slide rails. Specifically, when the return elastic member is a return spring, the return spring exerts a force on the connecting rod assembly or the caster. Under the spring force, so that the casters and the surface of the workpiece to be measured are close. In order to improve the stability of the lifting of the connecting rod group, the gun head mechanism of this embodiment also includes a slide rail fixedly installed on the gun rack, the connecting rod group can be lifted and mounted on the sliding rail, and the return spring is sleeved on the sliding rail. outside the rail and above the connecting rod set.

Embodiment 3

[0040] This embodiment discloses a method for controlling the height of the print head described in Embodiment 1 and Embodiment 2, which includes the following steps:

[0041] A. The control system sets the preset distance L1 between the print head and the surface of the workpiece according to the process requirements;

[0042] B. The distance detection component detects the distance L2 between it and the connecting rod group, and transmits the detection result to the control system;

[0043] C. The control system calculates the distance L3 between the print head and the surface of the workpiece according to the detection results of the distance detection component, and compares L3 with L1 to obtain the deviation. The control system adjusts the height of the print head according to this deviation.

[0044] Wherein, the control system is preferably a programmable logic controller (abbreviated as PLC).

[0045] The invention realizes the closed-loop control of the height of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com