Wafer bonding method

A wafer bonding and wafer technology, applied in precision positioning equipment, microstructure technology, microstructure devices, etc., can solve problems such as difficult control of wafer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] There are many problems with wafer bonding methods, for example, the spacing between wafers is not easy to control.

[0023] Now combine a wafer bonding method to analyze the reasons why the spacing between wafers is not easy to control:

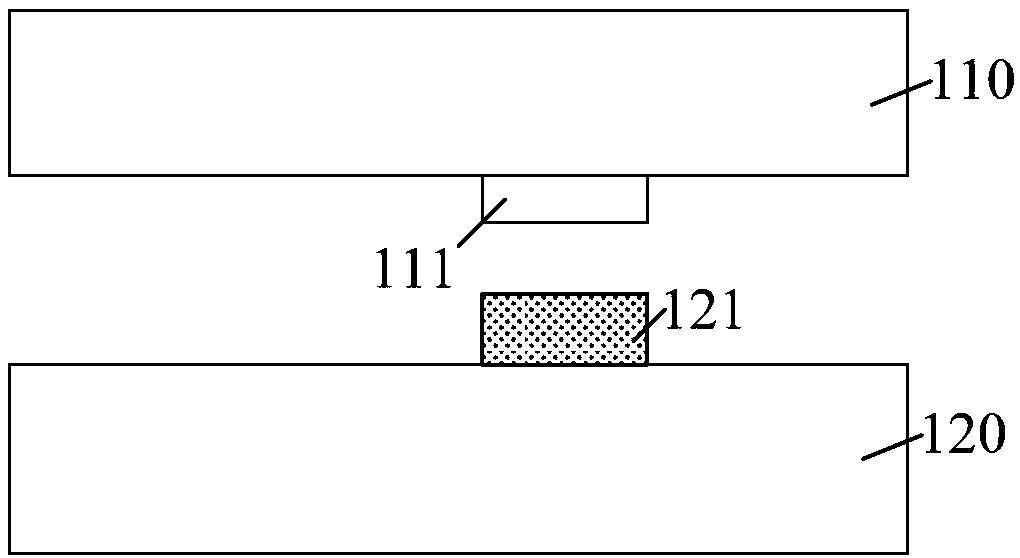

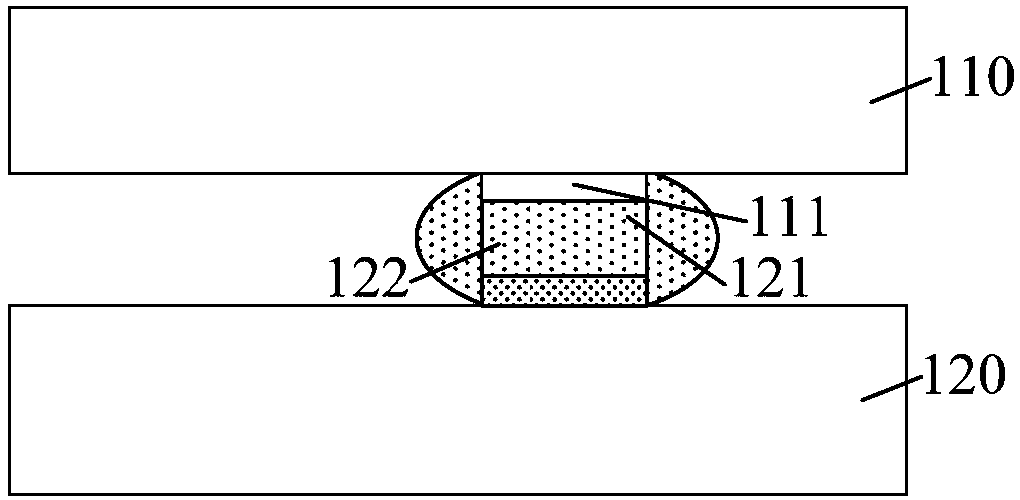

[0024] figure 1 with figure 2 It is a schematic diagram of the structure of each step of a wafer bonding method.

[0025] Please refer to figure 1 , Provide a CMOS wafer 110 and a MEMS wafer 120, the CMOS wafer 110 includes a first bonding surface, the MEMS wafer 120 includes a second bonding surface; a first bonding surface is formed on the surface of the first bonding surface Interconnection layer 111; a second interconnection layer 121 is formed on the surface of the second bonding surface.

[0026] Please refer to figure 2 , The first interconnection layer 111 is bonded to the second interconnection layer 121; the first interconnection layer 111 and the second interconnection layer 121 are bonded to make the first interconnection layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com