Prefabricated partition wall construction method

A construction method and partition wall panel technology, which is applied to building structures, walls, buildings, etc., can solve the problems of low connection strength, low work efficiency, and poor integrity between prefabricated columns and prefabricated partition panels, and achieve simple installation and work. High efficiency and good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, prefabricated partition wall construction method of the present invention will be further described:

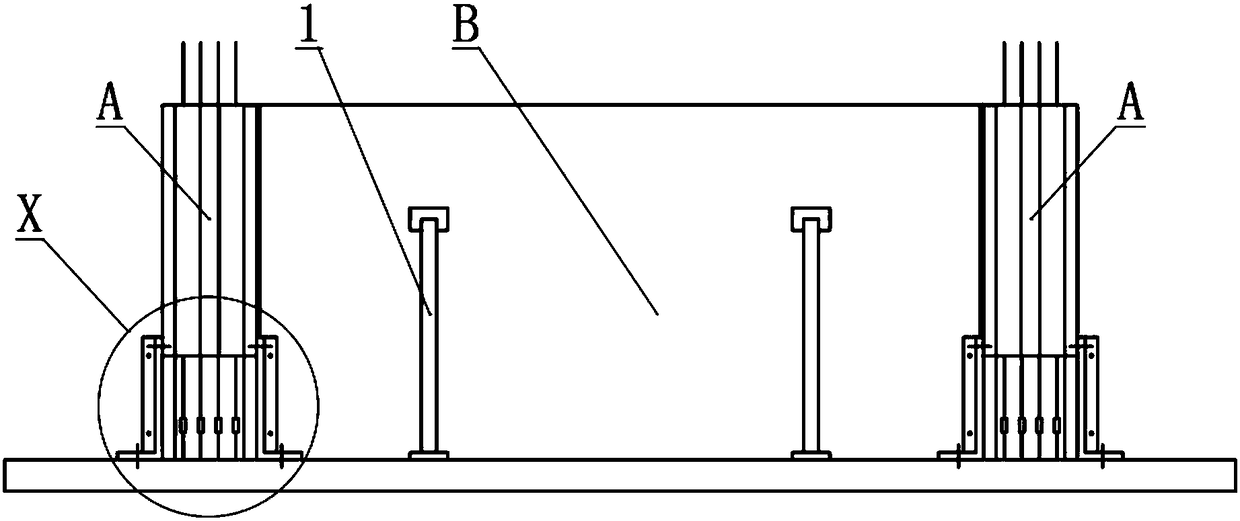

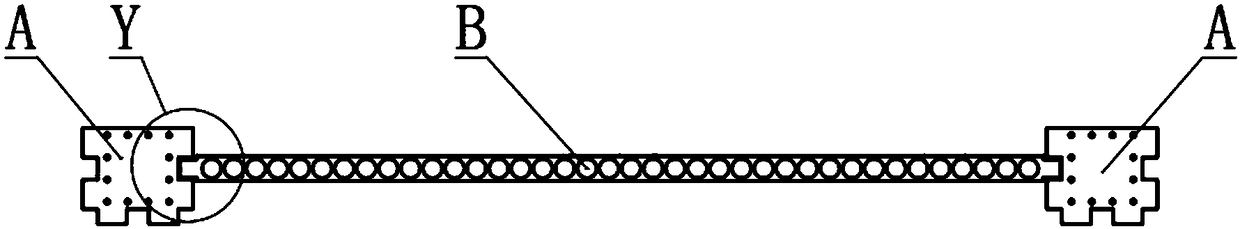

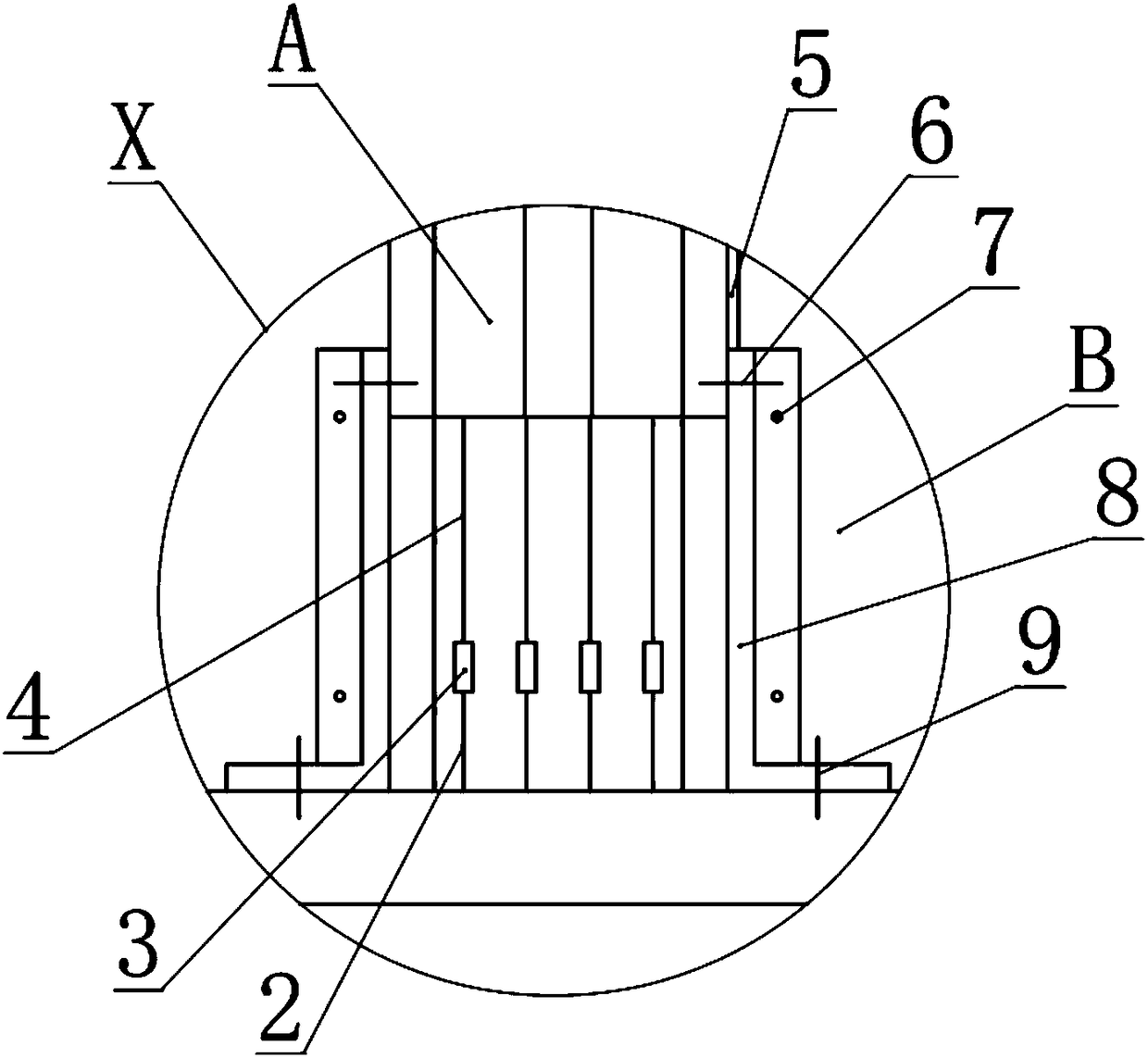

[0035] Such as figure 1 with figure 2 As shown, the prefabricated partition wall construction method of the present invention is mainly composed of several prefabricated pillars, several fast prefabricated partition wall panels and several prefabricated floor slabs. The two ends of the pillar A are provided with outstretched steel bars 4 protruding from the outside, and the outer surface of the pillar A is Mounting lugs 10 and mounting grooves 11 are provided on the top, and mounting flanges 12 are provided at both ends of the partition board B to facilitate the installation and connection with the column A.

[0036] Such as image 3 with Figure 4 As shown, first install the column A, and then install the partition wall board B. After the extended steel bar 4 at the bottom of the column A is connected and fixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com