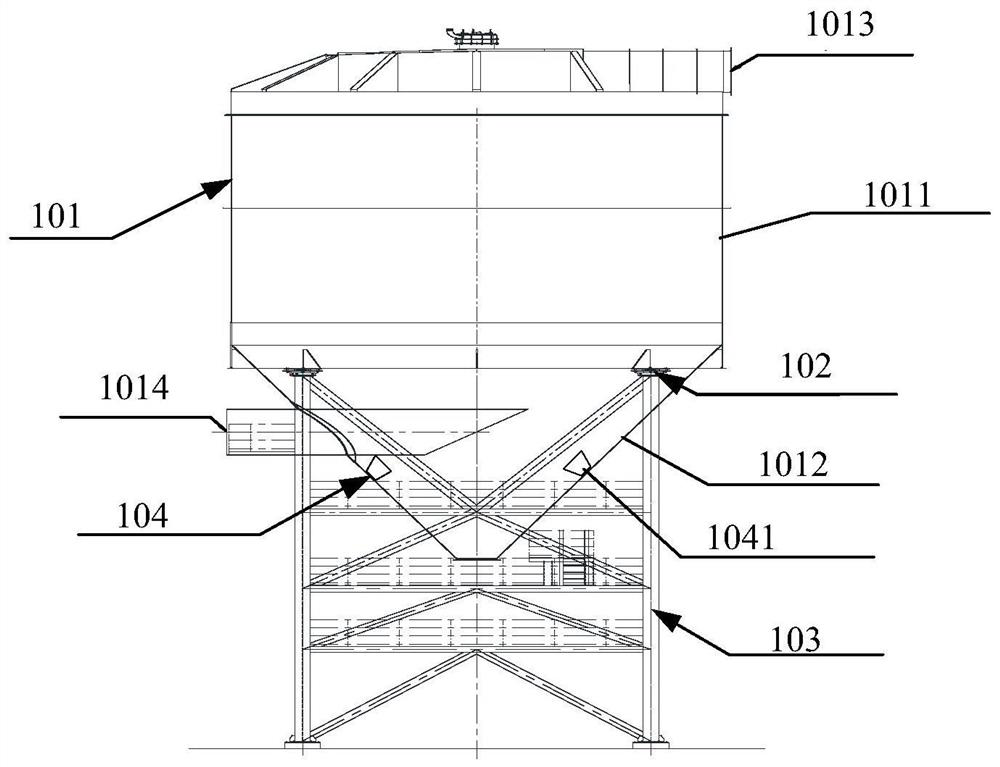

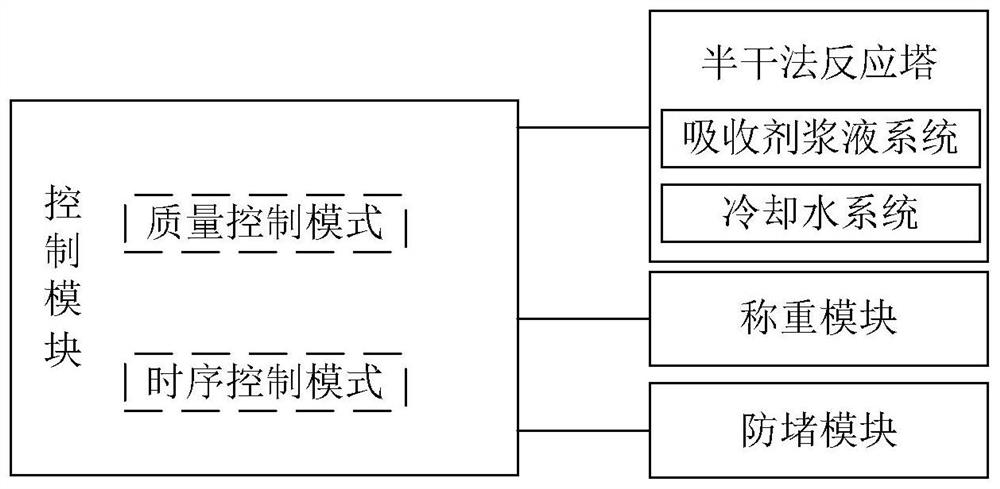

A semi-dry reaction tower control system

A control system and reaction tower technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of failure to guarantee the safety, reliability and economy of reaction tower operation, flattening of flue gas outlets, ash hoppers, etc. Load increase and other problems can be avoided to avoid excessive internal dust accumulation, reduce safety risks, and reduce energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

[0037] In order to thoroughly understand the present invention, a detailed description will be provided in the following description to illustrate the semi-dry reaction tower control system of the present invention. Obviously, the practice of the invention is not limited to specific details familiar to those skilled in the field of waste incineration. Preferred embodiments of the present invention are described in detail below, however, the present invention may have other embodiments besides these detailed descriptions.

[0038] It should be noted that the te...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap