Vertical plastic assistant screening machine

A screening machine, plastic technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of long screening time, poor screen effect, etc., to achieve the effect of reducing accumulation, strong practicability, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

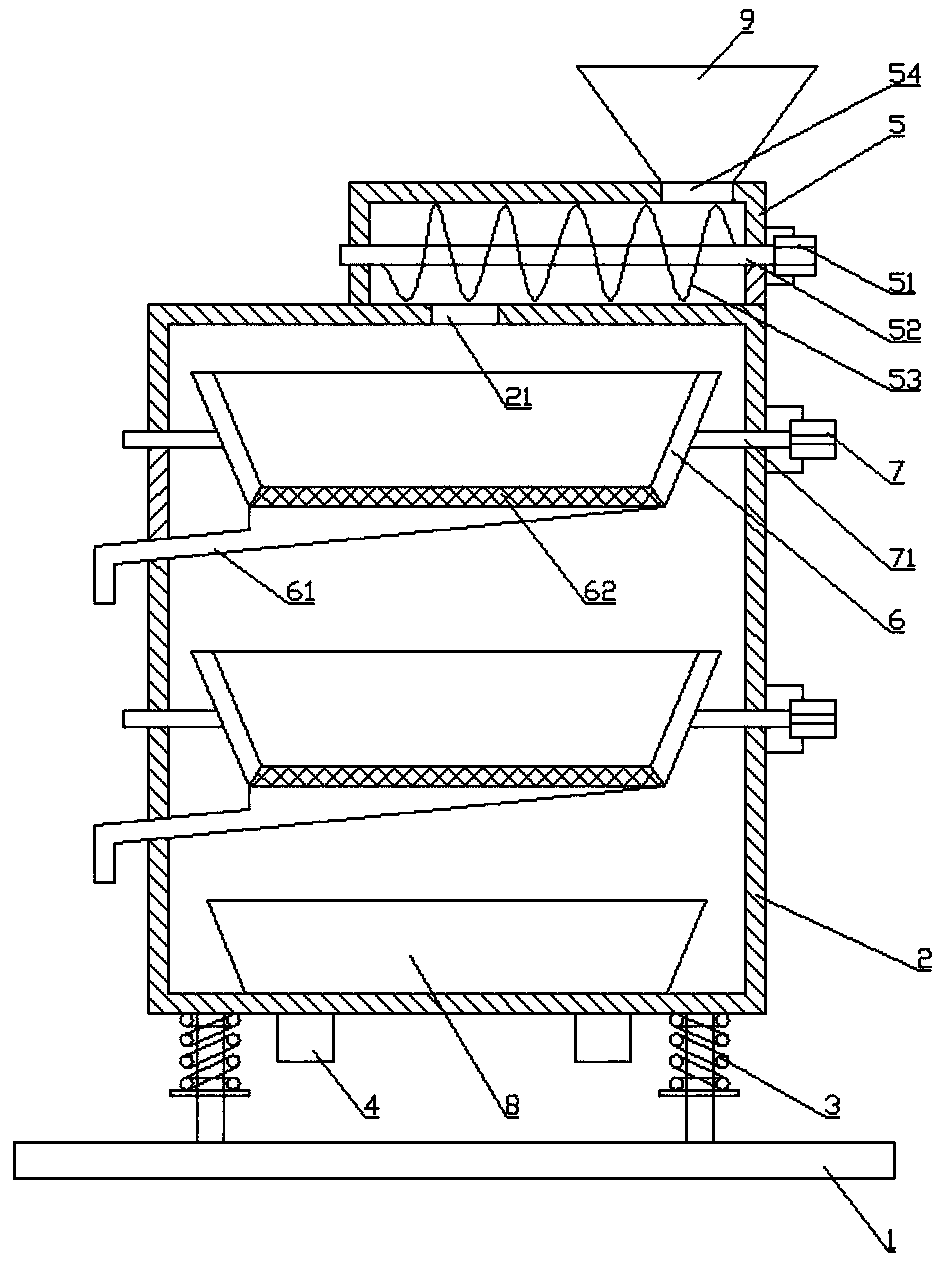

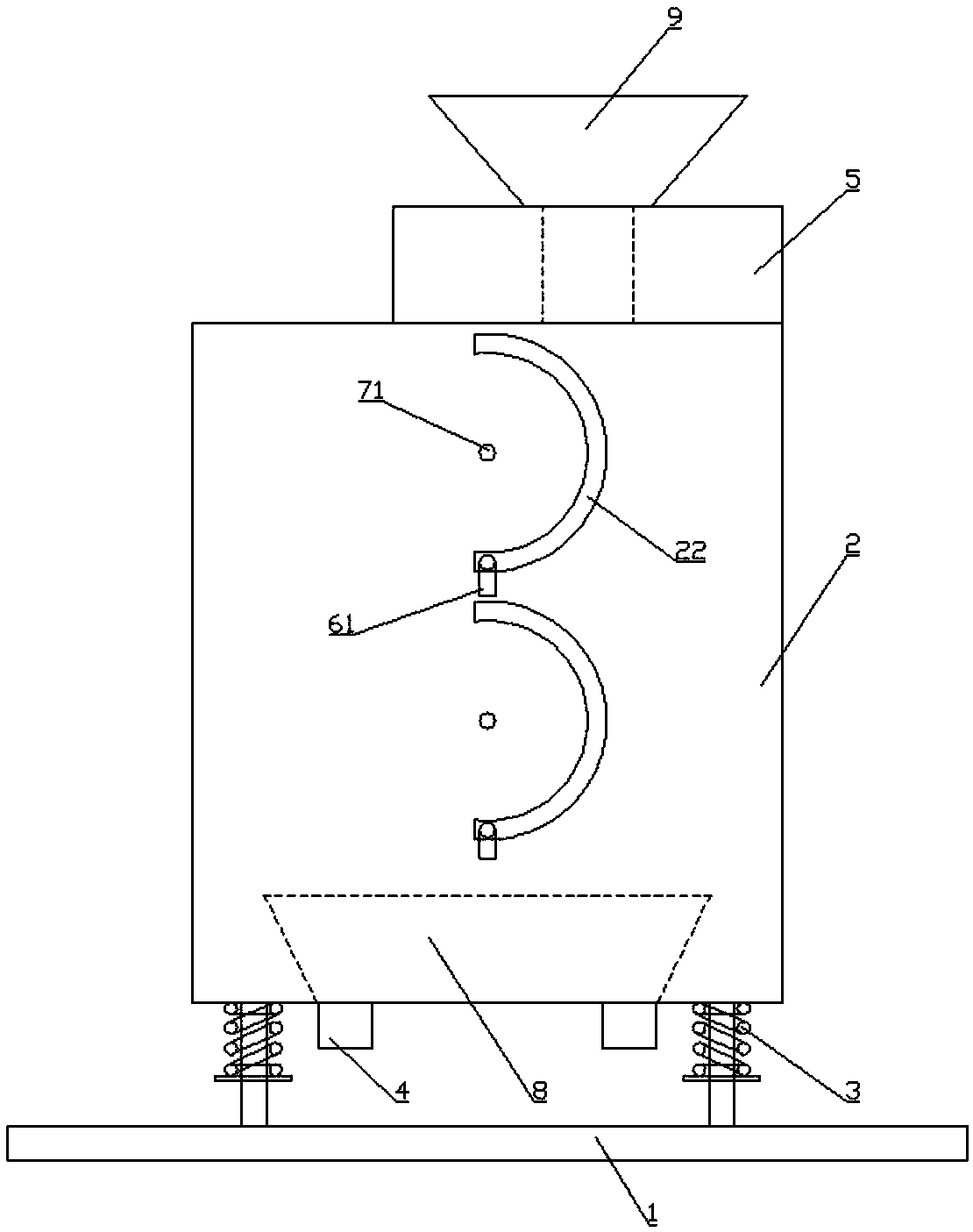

[0014] as attached figure 1 , 2 Shown is a vertical plastic auxiliary screening machine according to the present invention, including a screening box 2 and a bracket 1; the screening box 2 and the bracket 1 are connected by springs 3; the four corners of the bottom of the screening box 2 are provided with springs 3; 2. There is a vibration motor 4 at the bottom; there are two vibration motors 4, which are symmetrically distributed at the bottom of the screening box 2 to provide a vibration source for the screening box 2; a feeding box 5 is arranged above the screening box 2; the feeding box 5 and the screening box 2 is communicated through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com