Photovoltaic welded strip straightening device

A straightening device and a technology for photovoltaic welding ribbons, which are applied to belts, other household appliances, household appliances, etc., can solve the problems of easy bending of welding ribbons, achieve smooth surface of welding ribbons, improve straightness, and reduce relative sliding friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them.

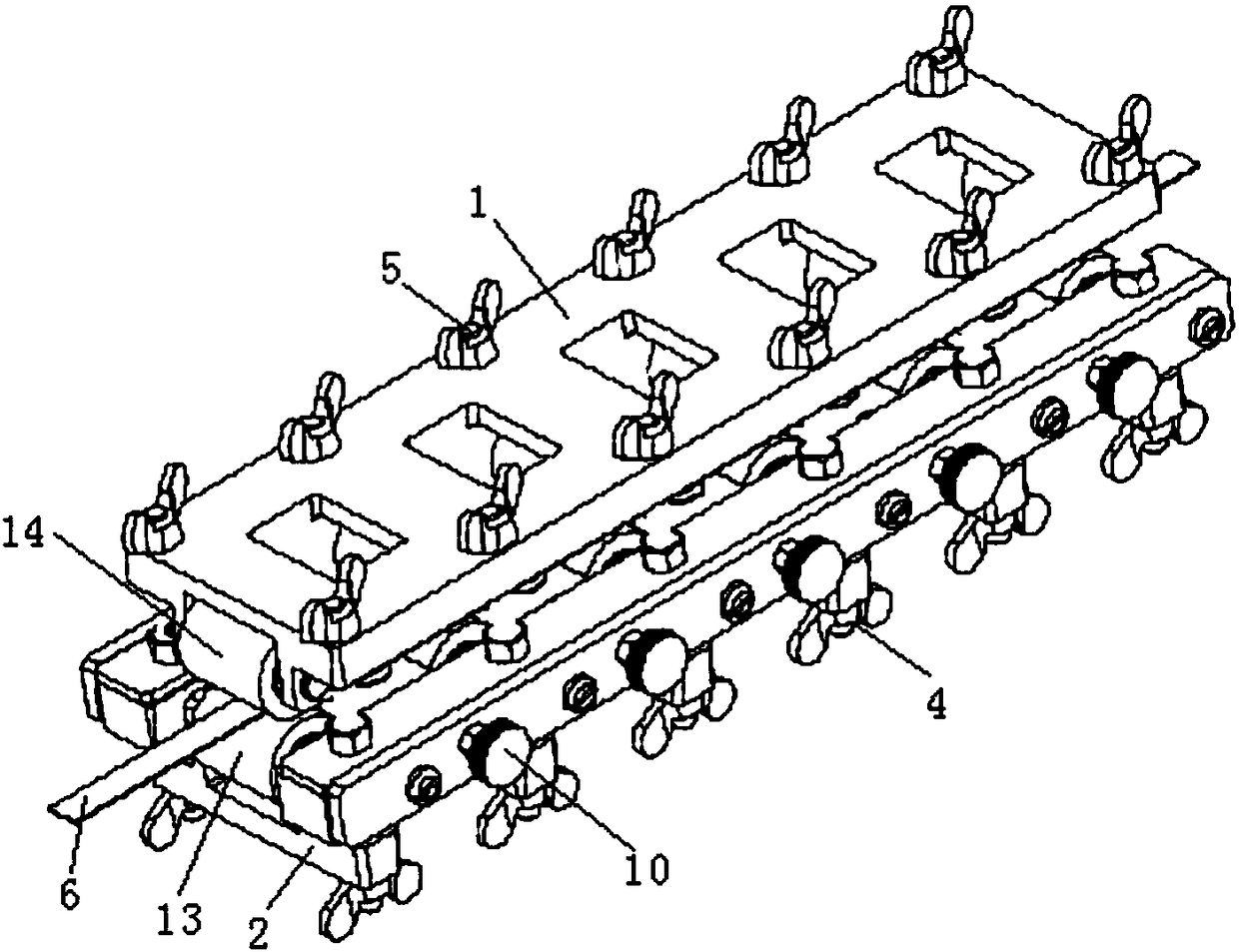

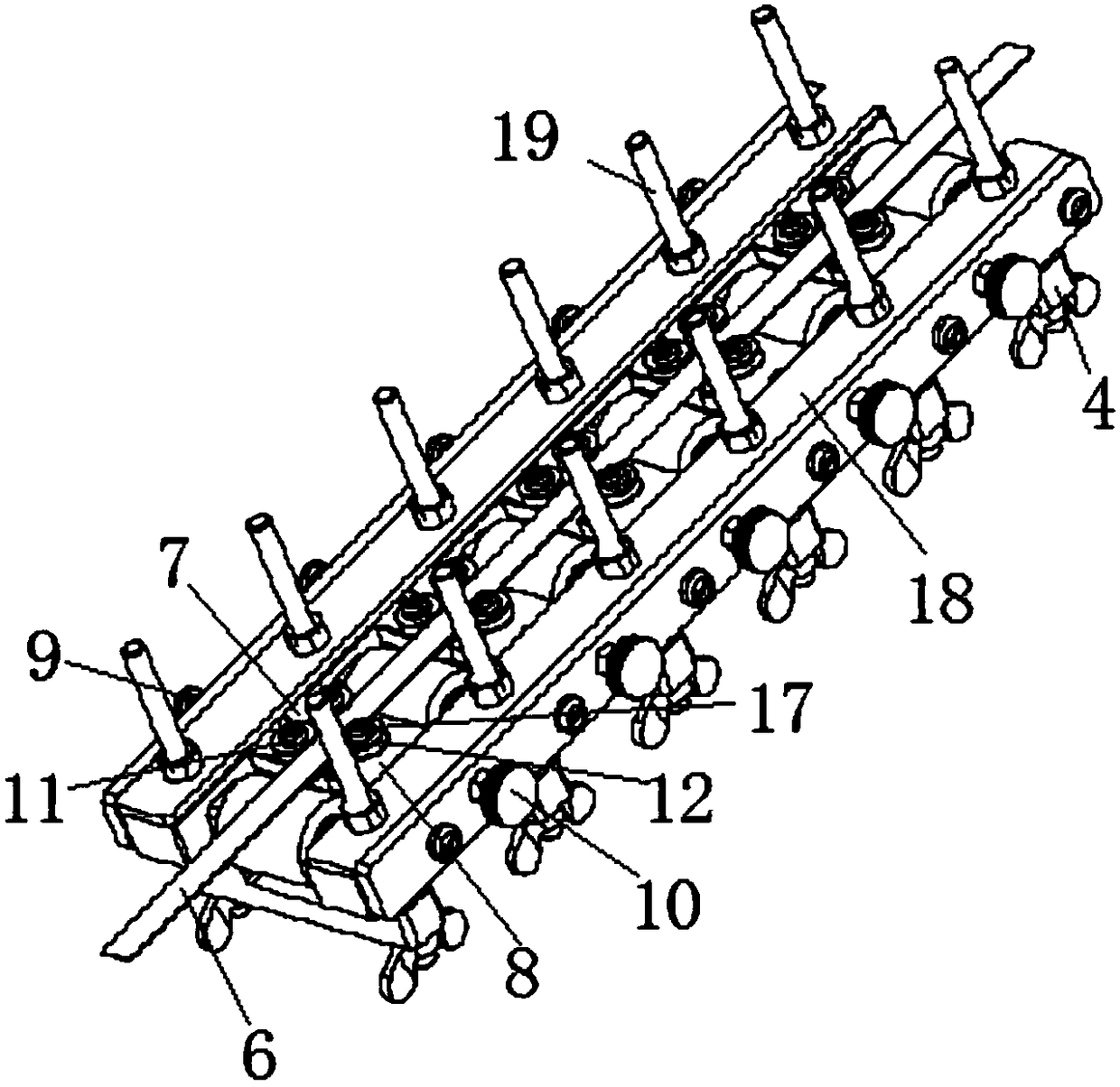

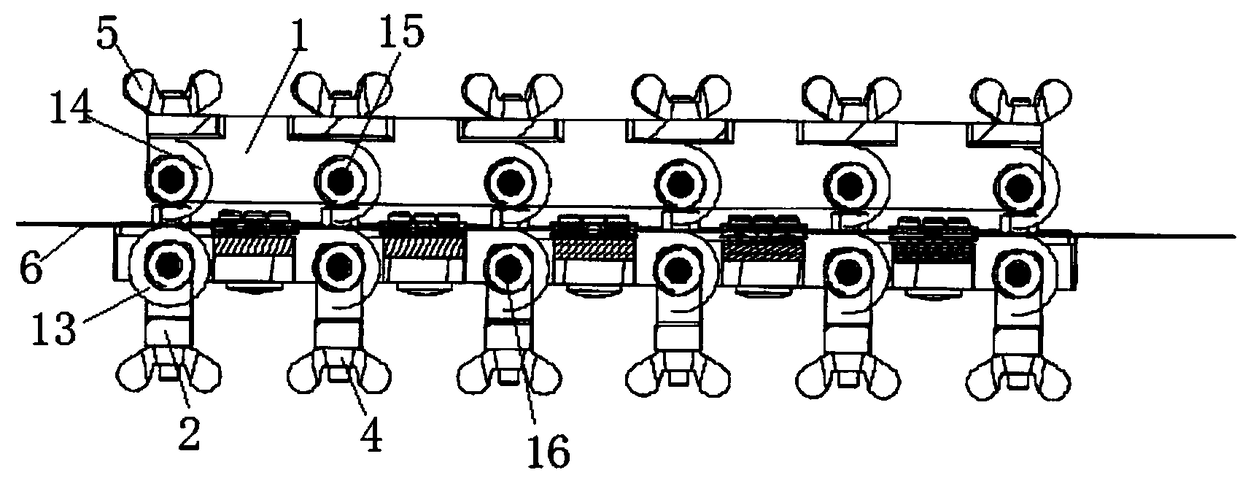

[0015] refer to Figure 1-3 , a photovoltaic ribbon straightening device, comprising a frame 18 and a ribbon 6, a plurality of equidistantly arranged adjustment parts 2 are arranged below the frame 18, and a plurality of adjusting parts 2 arranged at equal distances are arranged above the frame 18, corresponding to the position of the frame 18. The compression part 1, the compression part 1 and the adjustment part 2 are all connected with the frame 18 through a plurality of screw rods 19, and the end of the screw rod 19 located under the adjustment part 2 is threadedly connected with the first adjustment nut 4, and the screw rod 19 is located in the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com