Mechanical device for resistance spot welding

A mechanical device, resistance spot welding technology, applied in resistance welding equipment, resistance electrode bases, electrode features, etc., can solve the problems of rising construction costs and material costs, damage to the signal line of the servo motor, and adjustment of the upper and lower moving and static arms. Achieve the effect of improving the standardized design of the clamp body, improving the design efficiency and manufacturing efficiency, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

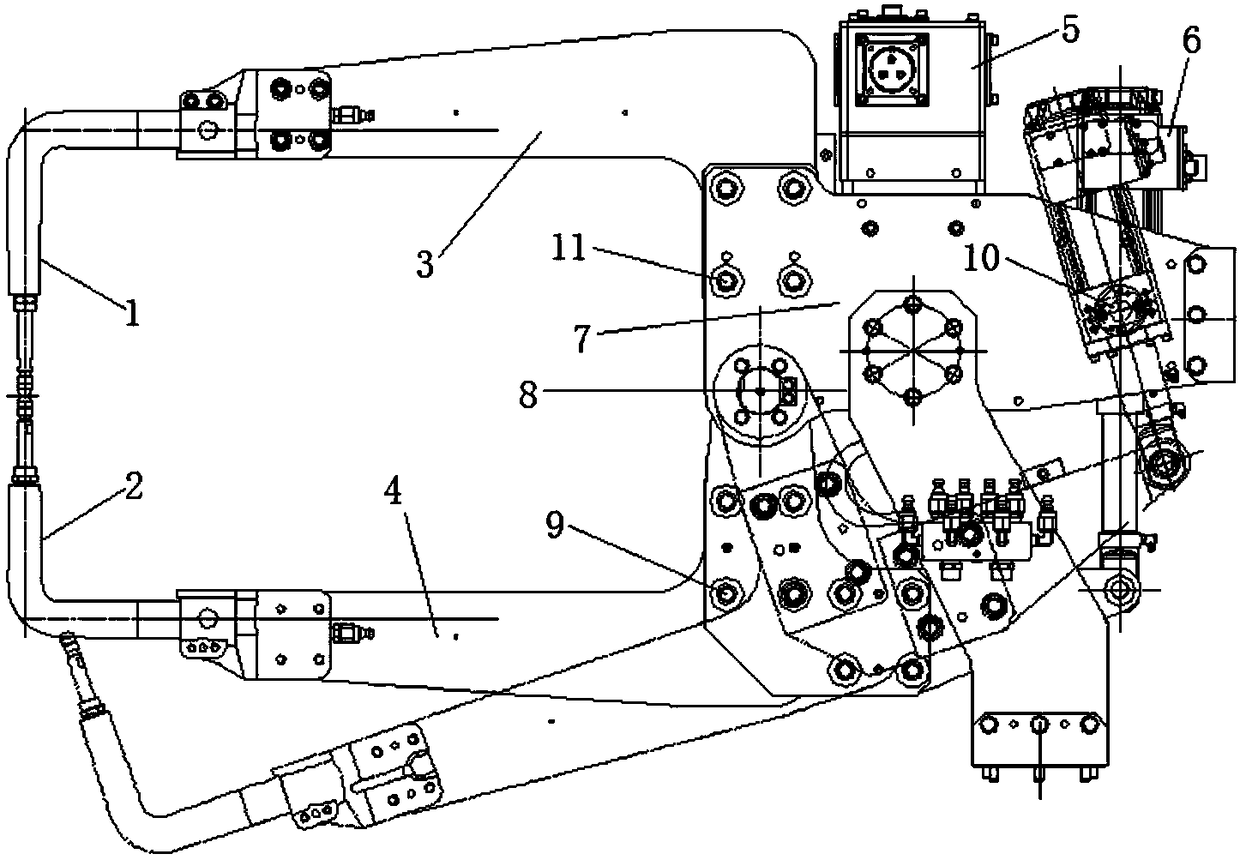

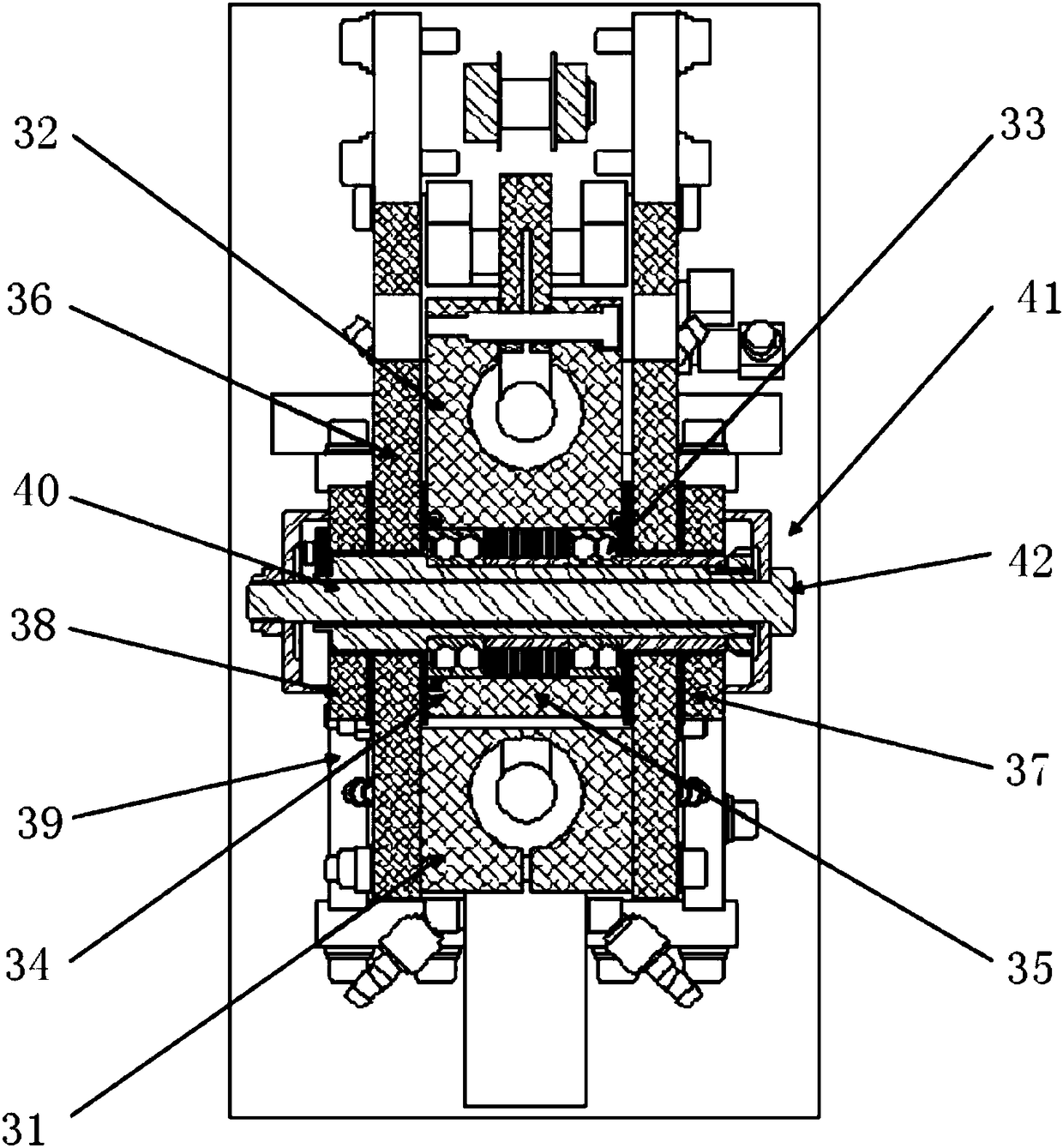

[0016] According to attached figure 2 As shown, the present invention discloses a mechanical device for resistance spot welding, which includes a welding tongs body, an integrated servo motor 16 connected to the welding tongs body, and a transformer 26 connected to the welding tongs body. The welding tongs body includes an upper electrode 12. The lower electrode 13, the boom 14, the static arm 15, the boom seat 19, the clamp body 23 and the clamp body support shaft 27, the upper electrode 12 and the lower electrode 13 are set up and down relative to the working position, and the upper electrode 12 is set on the swing arm 14, the lower electrode 13 is set on the static arm 15, the mounting hole 29 is reserved on the movable arm base 19, and the mounting hole 30 is also reserved on the static arm base. The servo motor 16 is connected to the clamp through the servo fixing screws 25 on both sides. body 23, the end of the servo motor 16 is provided with a flange 24, the push rod o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com