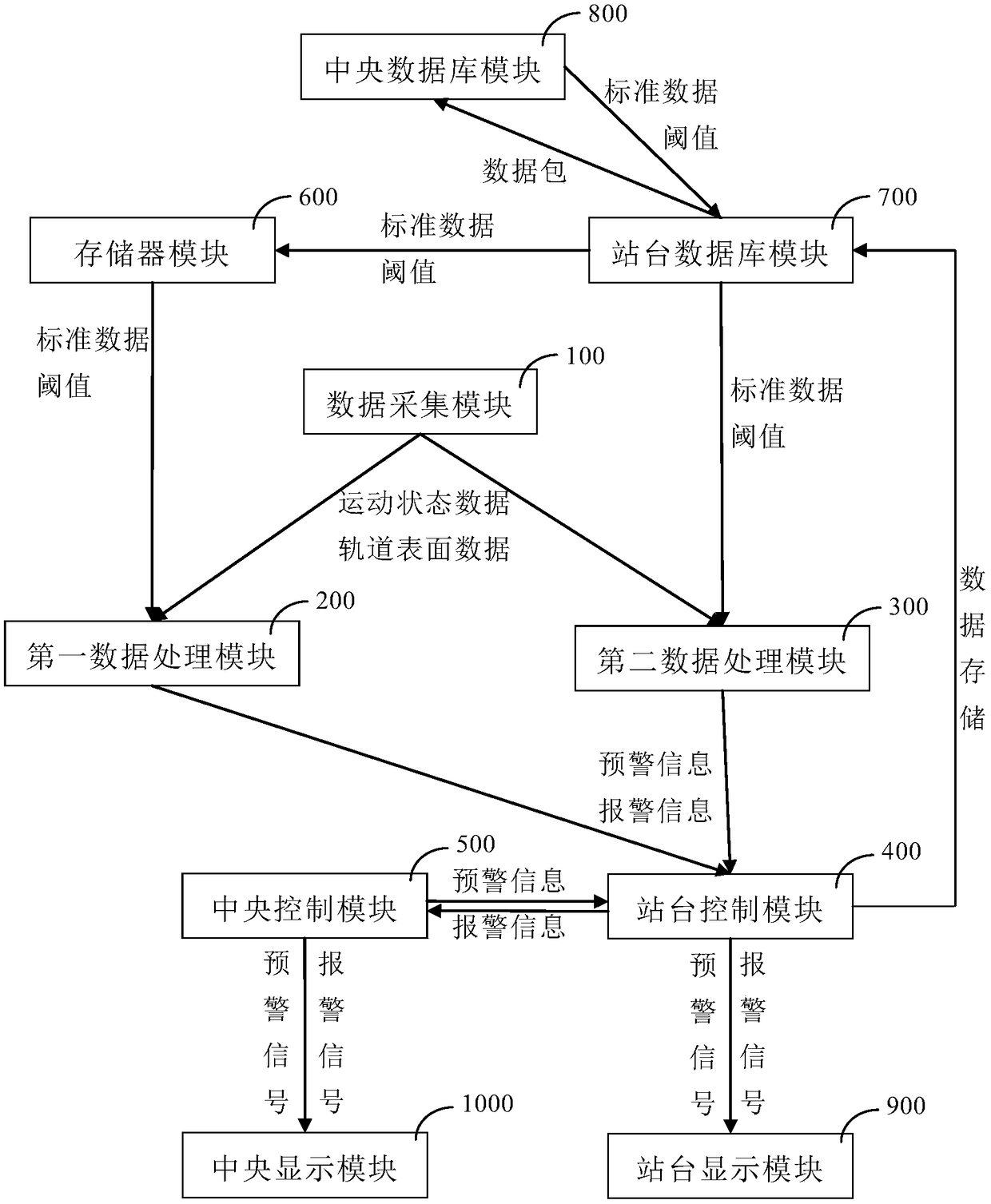

Self-inspection system for rail traffic intelligent routing inspection robot

An intelligent inspection and rail transit technology, applied in railway traffic management, transportation center control system, manipulators, etc., can solve the problem that the track cannot be detected by itself, and achieve strong anti-electromagnetic interference ability, easy connection, and guaranteed timeliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] When a foreign object appears on the track 2 running on the intelligent inspection robot 1, such as Figure 4 shown, perform the following steps:

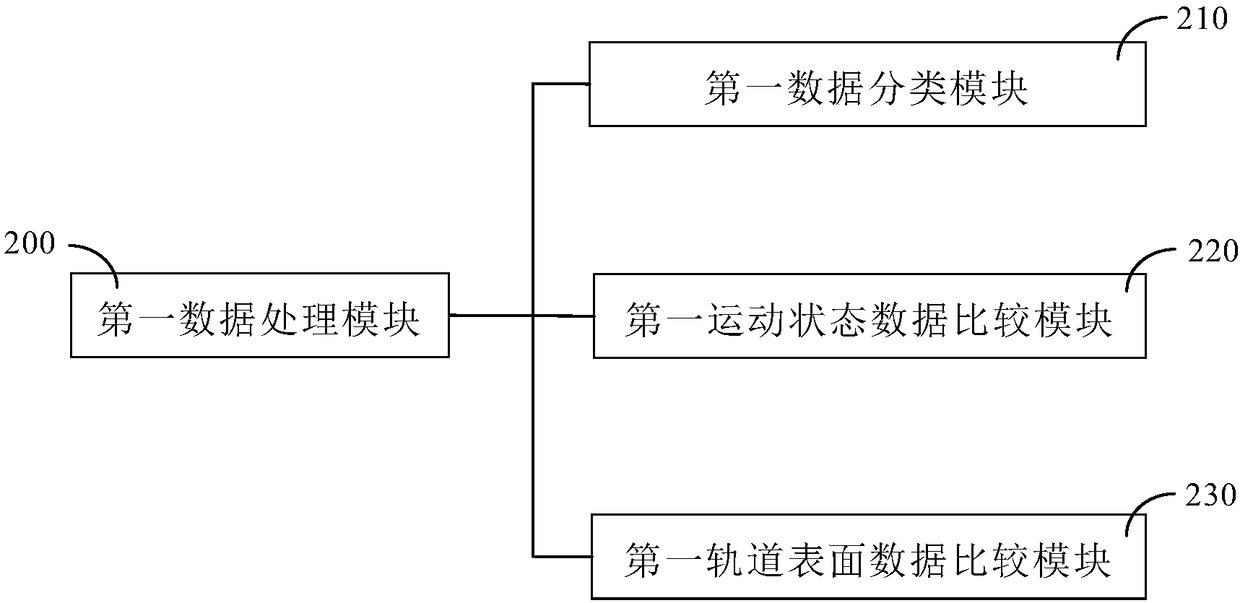

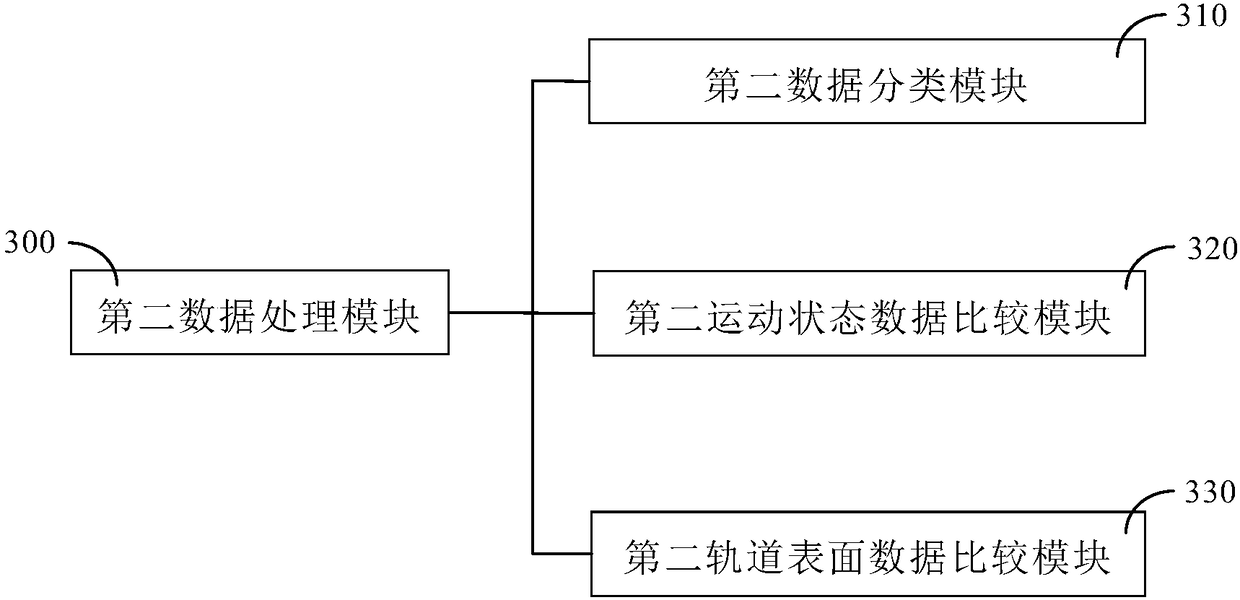

[0071] S11, data collection: the optical fiber sensor 3 collects track surface data in real time and transmits it to the data classification module 210 in the first data processing module 200;

[0072] S12, data classification: the data classification module 210 transmits the track surface data to the track surface data comparison module 220;

[0073] S13, early warning judgment: the track surface data comparison module 230 compares the track surface data with the standard data transmitted by the memory module 600, when the size and shape of the foreign matter exceed the early warning threshold, generate early warning information and enter step S14, when the size and shape of the foreign matter When the warning threshold is not exceeded, go to step S17;

[0074] S14, alarm judgment: the track surface data comparison module...

Embodiment 2

[0082] When cracks appear on the track 2 running on the intelligent inspection robot 1, such as Figure 5 shown, perform the following steps:

[0083] S21, data acquisition: the optical fiber sensor 3 collects track surface data in real time and transmits it to the data classification module 210 in the first data processing module 200;

[0084] S22, data classification: the data classification module 210 transmits the track surface data to the track surface data comparison module 230;

[0085] S23, early warning judgment: the track surface data comparison module 230 compares the track surface data with the standard data transmitted by the memory module 600, when the size of the crack exceeds the early warning threshold, generates early warning information and enters step S24, when the size of the crack does not exceed the early warning threshold , enter step S27;

[0086] S24, alarm judgment: the track surface data comparison module 230 compares the track surface data with t...

Embodiment 3

[0094] When the intelligent inspection machine 1 moves too fast, such as Figure 6 shown, perform the following steps:

[0095] S31, data collection: the optical fiber sensor 3 collects the motion speed of the intelligent inspection robot 1 in real time and transmits it to the data classification module 210 in the first data processing module 200;

[0096] S32, data classification: the data classification module 210 transmits the motion speed of the intelligent inspection robot 1 to the motion state data comparison module 220;

[0097] S33, early warning judgment: the motion state data comparison module 220 compares the motion speed of the intelligent inspection robot 1 with the standard speed transmitted by the memory module 600, and when the motion speed of the intelligent inspection robot 1 exceeds the early warning threshold, generate early warning information and enter the step S34, when the motion speed of the intelligent inspection robot 1 does not exceed the warning t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com