Novel single-punch tablet press

A new type of punching technology, applied in material forming presses, presses, magnetic separation, etc., can solve the problems of low yield and affect the quality of tableting, improve quality and yield, and create economic benefits and competition. force, ensuring uniform and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

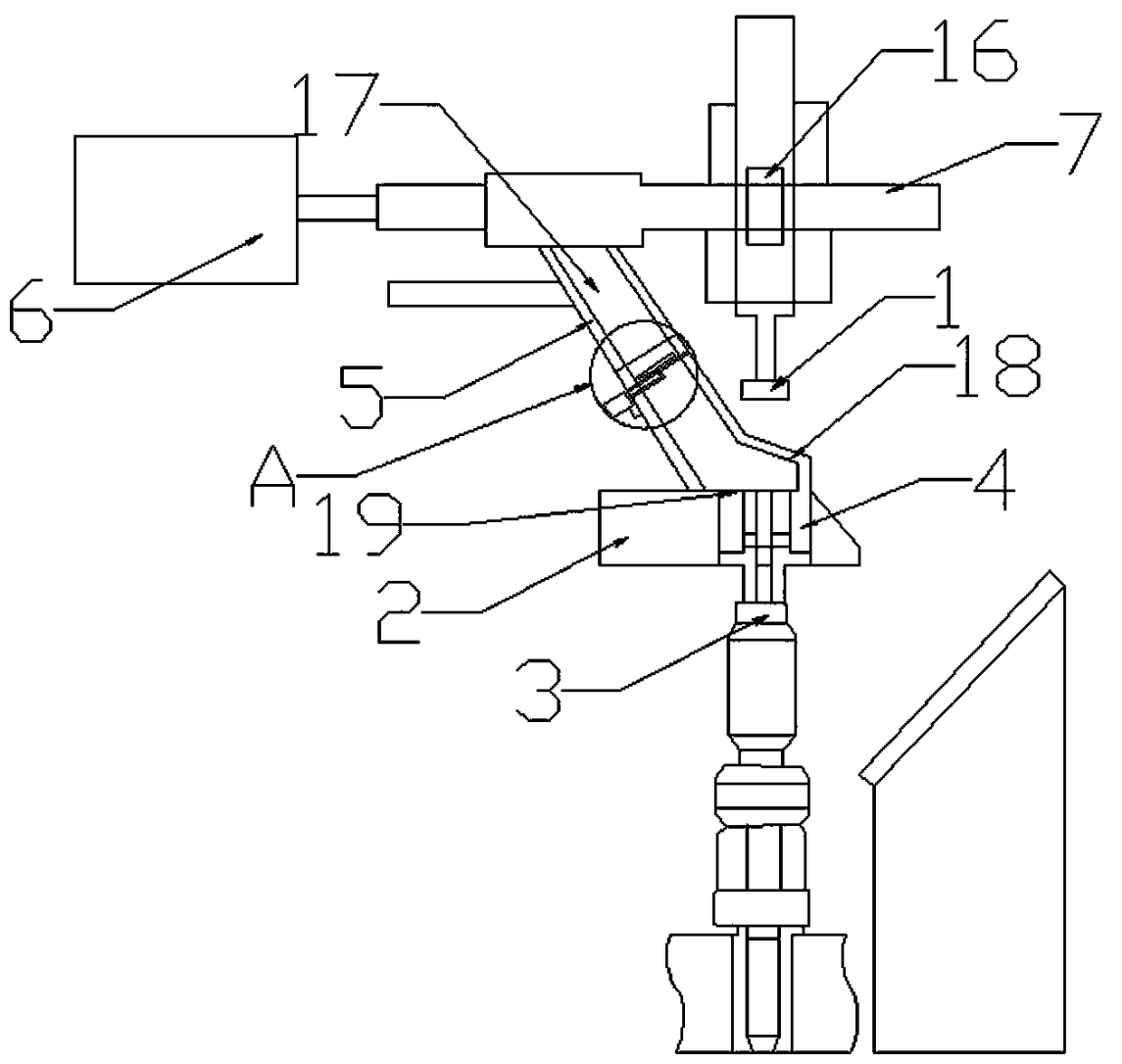

[0016] A kind of novel single-punch tablet press provided by the invention, such as figure 1 As shown, it includes an upper punch 1, a middle plate 2, a lower punch 3, a middle die hole 4, a hopper 5 and a drive motor 6, the middle die hole 4 is set on the middle plate 2, and the upper punch 1 is set on the Right above the middle die hole 4, the lower punch 3 is set directly below the middle die hole 4, the output end of the driving motor 6 is connected with a screw 7, the screw 7 is connected to the feeding hopper 5, and the middle section of the feeding hopper 5 is connected with a detachable Advanced magnetic separation and homogenization device, the magnetic separation and homogenization device can further magnetically separate and evenly divide the powder material to ensure the uniformity and stability of the powder.

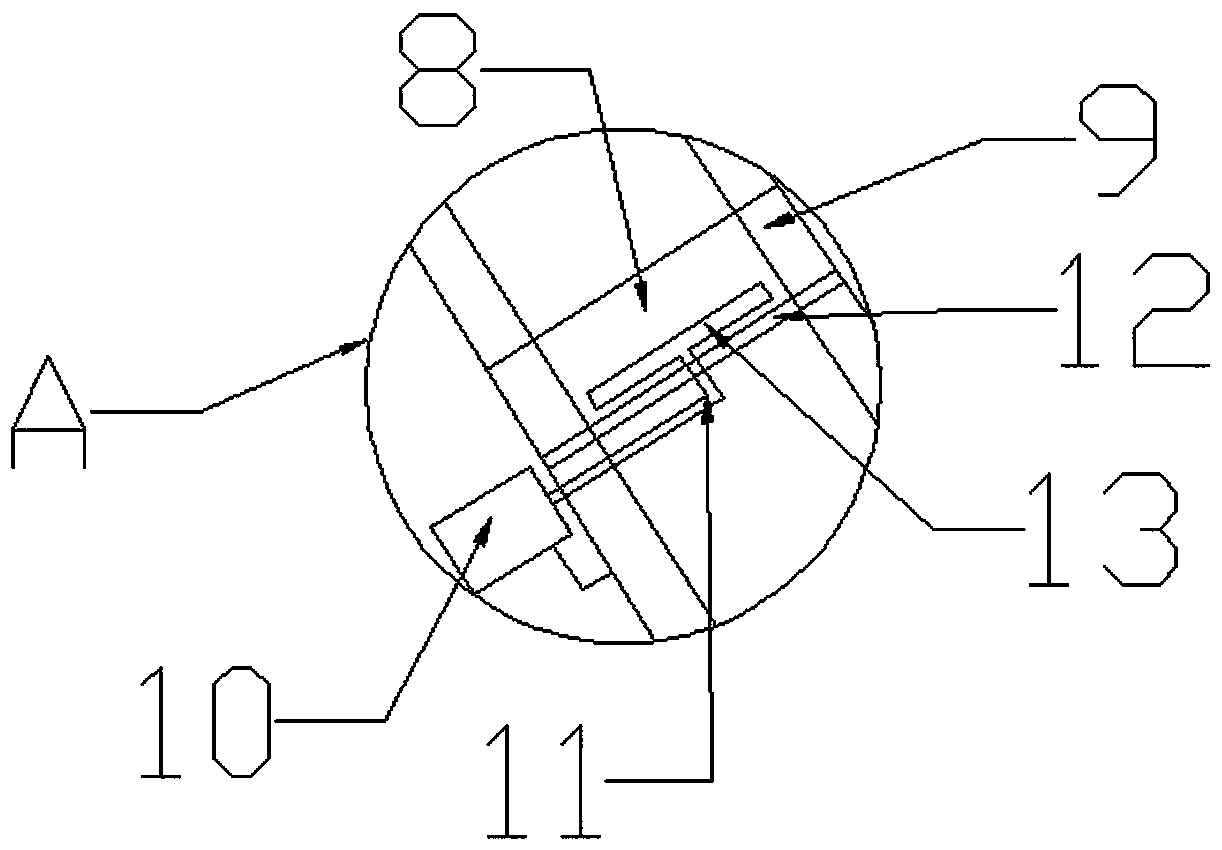

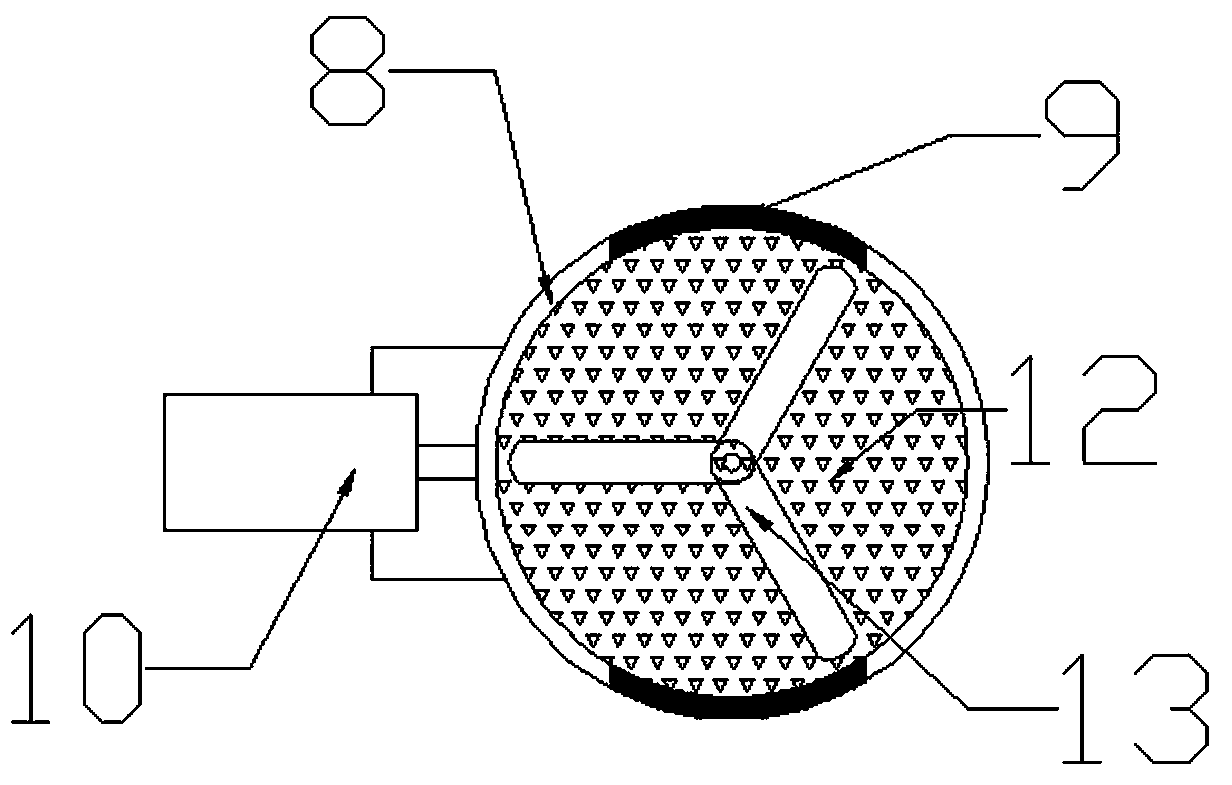

[0017] like figure 2 and image 3 As shown, the magnetic separation uniform material device includes a pipe body 8, a magnet 9, a motor 10, a connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com