Pneumatic tire

A technology for pneumatic tires and treads, applied in tire parts, tire treads/tread patterns, transportation and packaging, etc., can solve problems such as failure to suppress partial partial wear of main ribs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

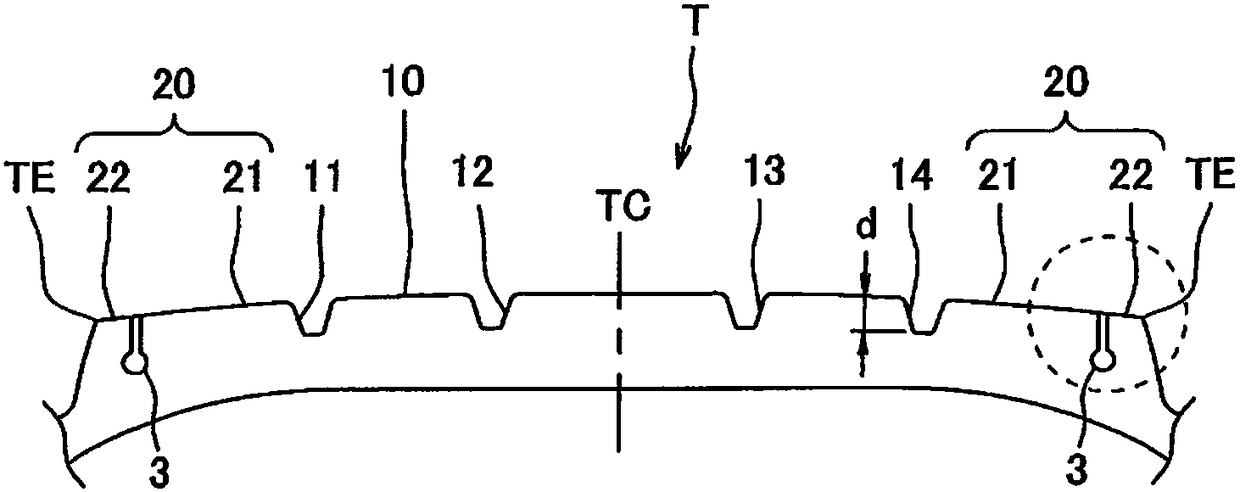

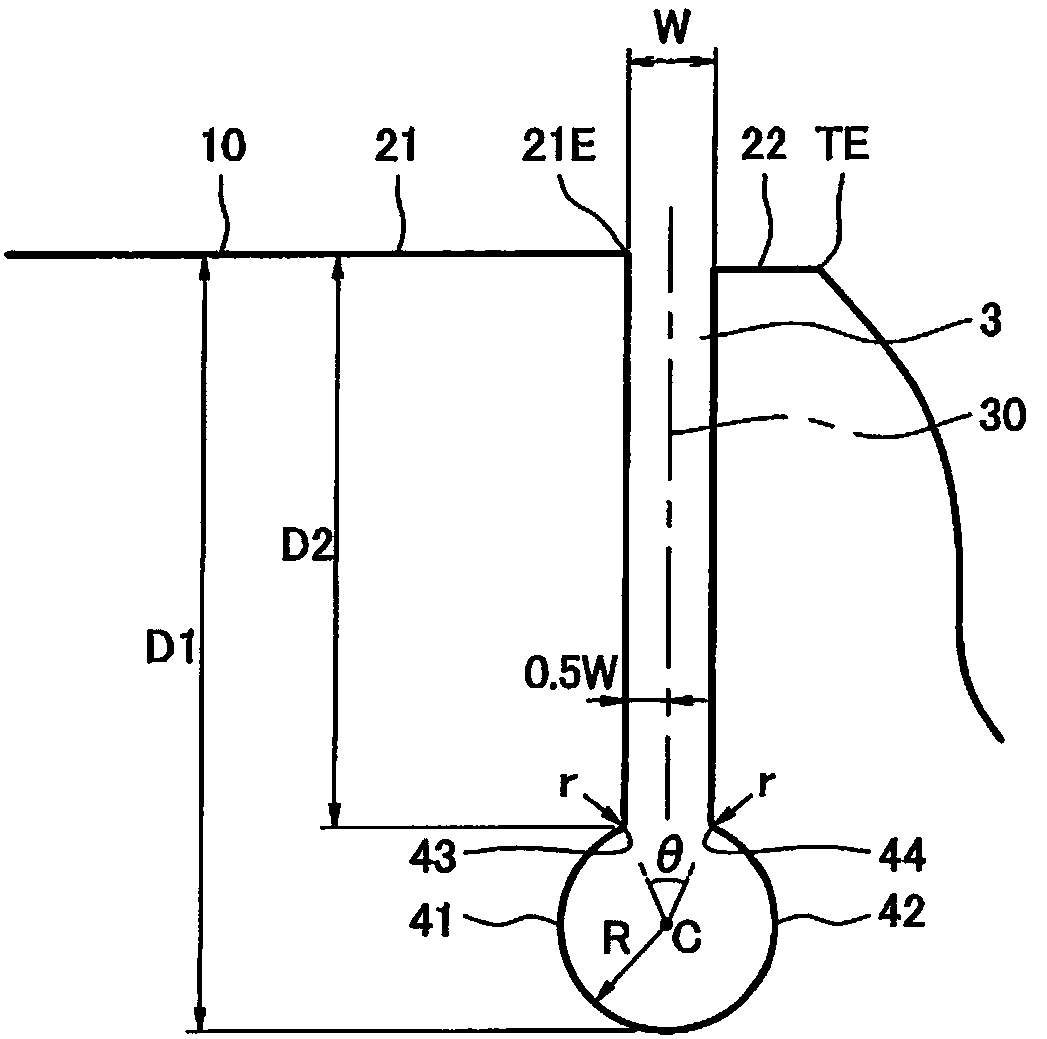

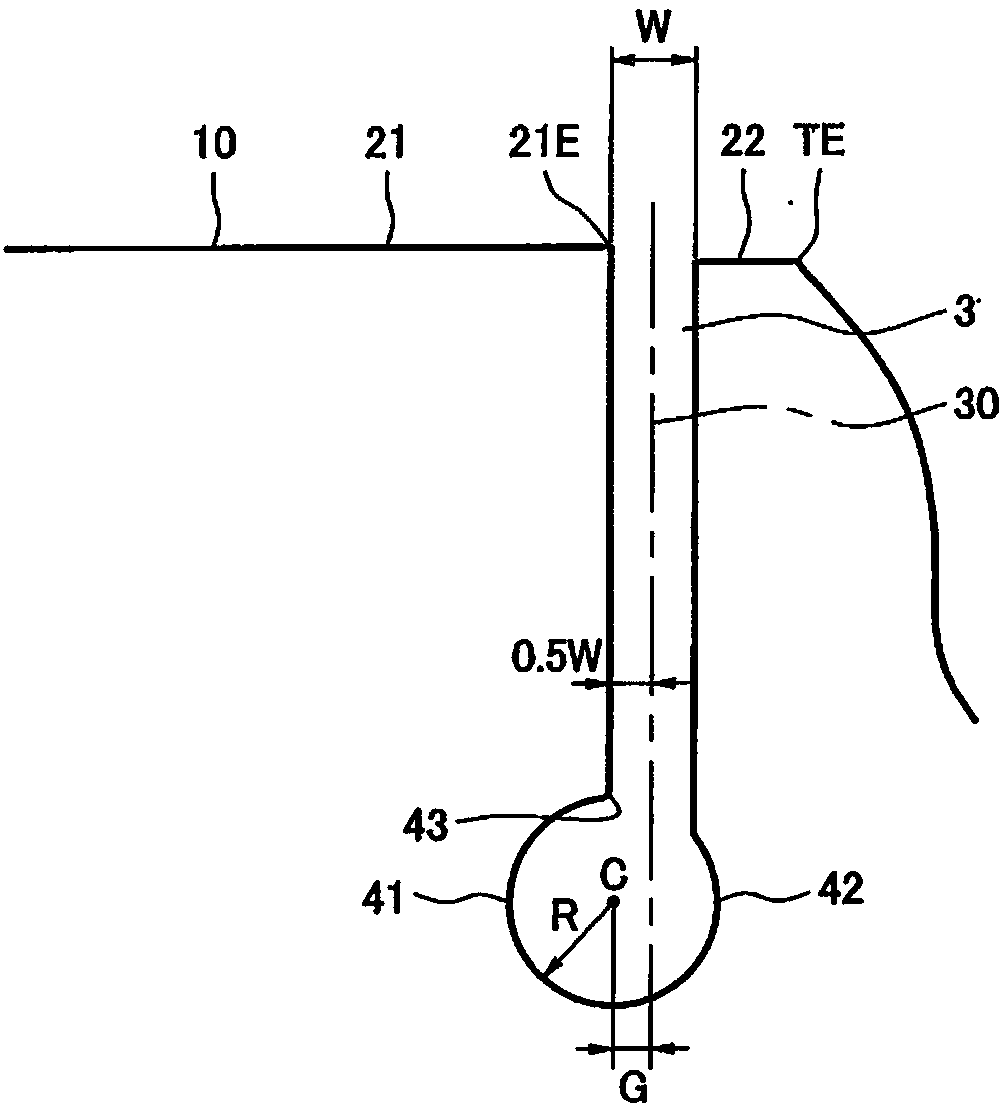

[0023] Embodiments of the present invention will be described with reference to the drawings. figure 1 The tread 10 of the pneumatic tire T of this embodiment is schematically shown. figure 2 Enlarged to show figure 1 The main part of the is surrounded by a dotted box.

[0024] This pneumatic tire T has, like a normal pneumatic tire, a pair of beads not shown and a pair of sidewalls extending radially outward from the beads, and the tread 10 is provided on each of the sidewalls. The radially outer ends of the tires are connected. In addition, a carcass extending in an annular shape is provided between a pair of beads, and reinforcing members such as a belt for reinforcing the carcass are embedded in the tread 10 , but illustration of these is omitted.

[0025] A plurality of main grooves extending in the tire circumferential direction are formed on the tread 10 , and in the present embodiment, four main grooves 11 to 14 are formed. The tread 10 is divided into a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com