Torque optimization method based on dual-motor layout and convex optimization algorithm for pure electric vehicles

A pure electric vehicle, convex optimization algorithm technology, applied in the direction of electric power unit, constraint-based CAD, power unit, etc., can solve the problems of high cost of pure electric vehicles, low efficiency of motor, large calculation burden, etc., and improve energy utilization Efficiency, saving vehicle cost, fast calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, the preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

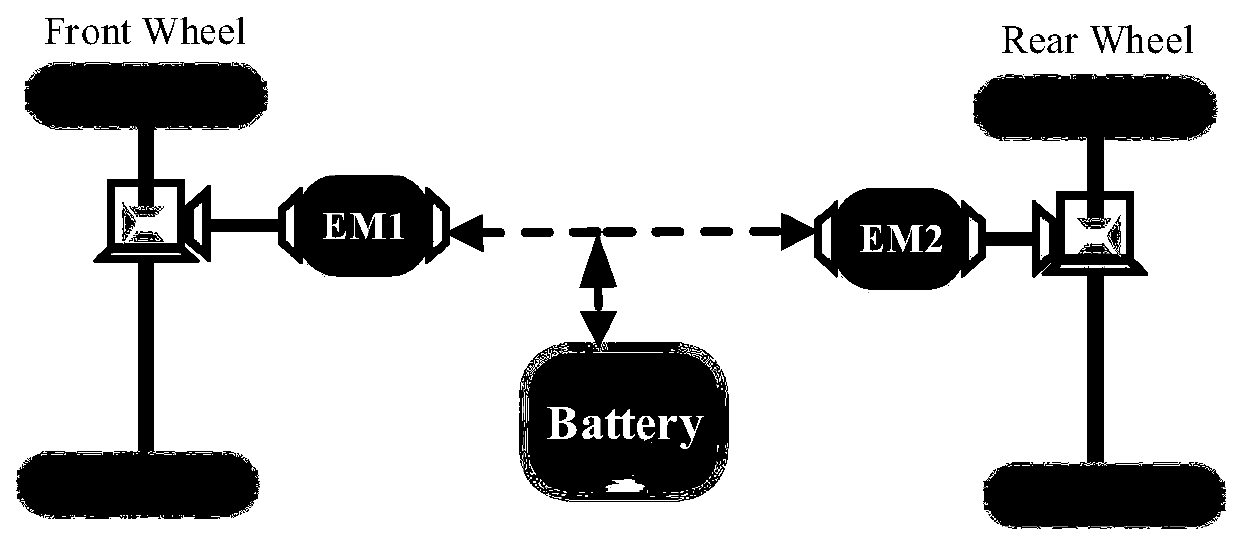

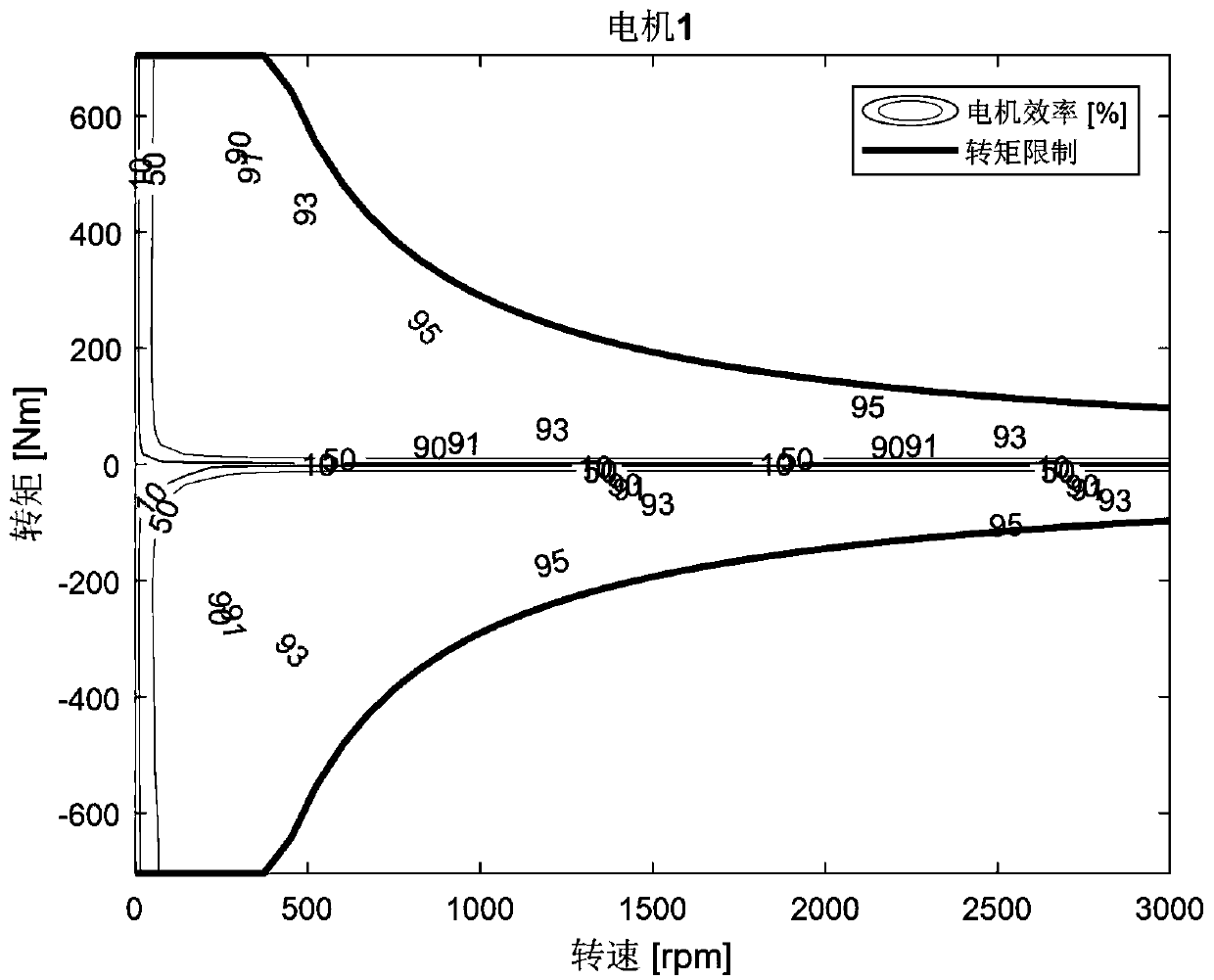

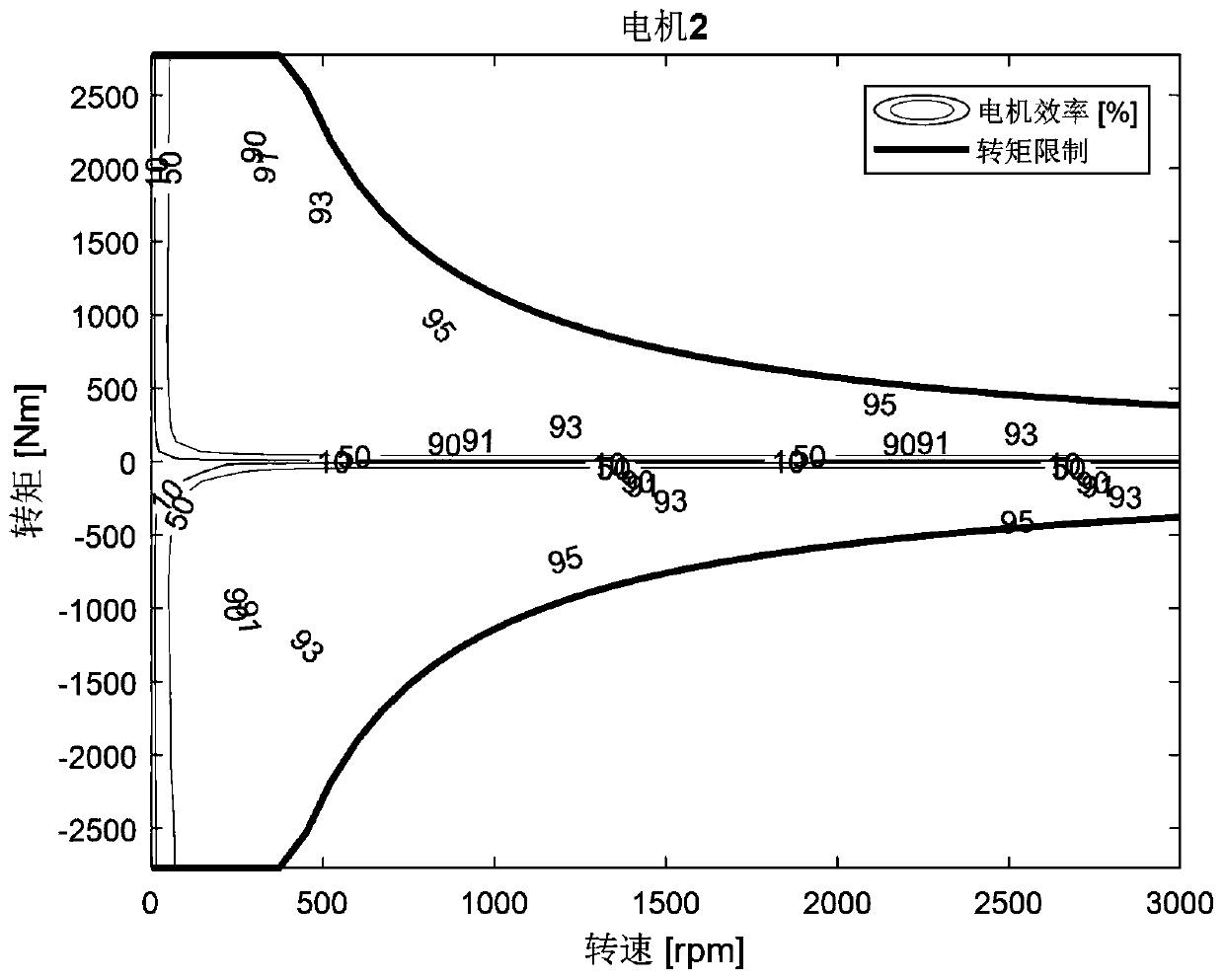

[0055] The implementation of the present invention can be realized by a pure electric bus model, such as figure 1 As shown, the electric vehicle model is equipped with two drive motors, which are respectively arranged on the front axle and the rear axle. The rear axle adopts a larger motor 2, and its maximum output torque and output power are both greater than that of the front axle motor 1. The efficiency diagram of the motor is as figure 2 , image 3 As shown, due to the different initial dimensions, the high efficiency regions of the two motors are also different. The high efficiency region of motor 1 is in the low torque (400N*m-800N*m) and high speed region, while the motor 2 is in high efficiency. Torque (600N*m-1000N*m), medium speed range. Because it is driven by two motors, the power of the car can be satisfied. In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com