Duct piece transport carrier and application method thereof

A bracket and segment technology, applied in the field of tunnel shield segment transportation device, can solve the problems of waste of materials, mutual collision of segments, low cost, etc., and achieve the effects of reduced use cost, high transportation safety and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

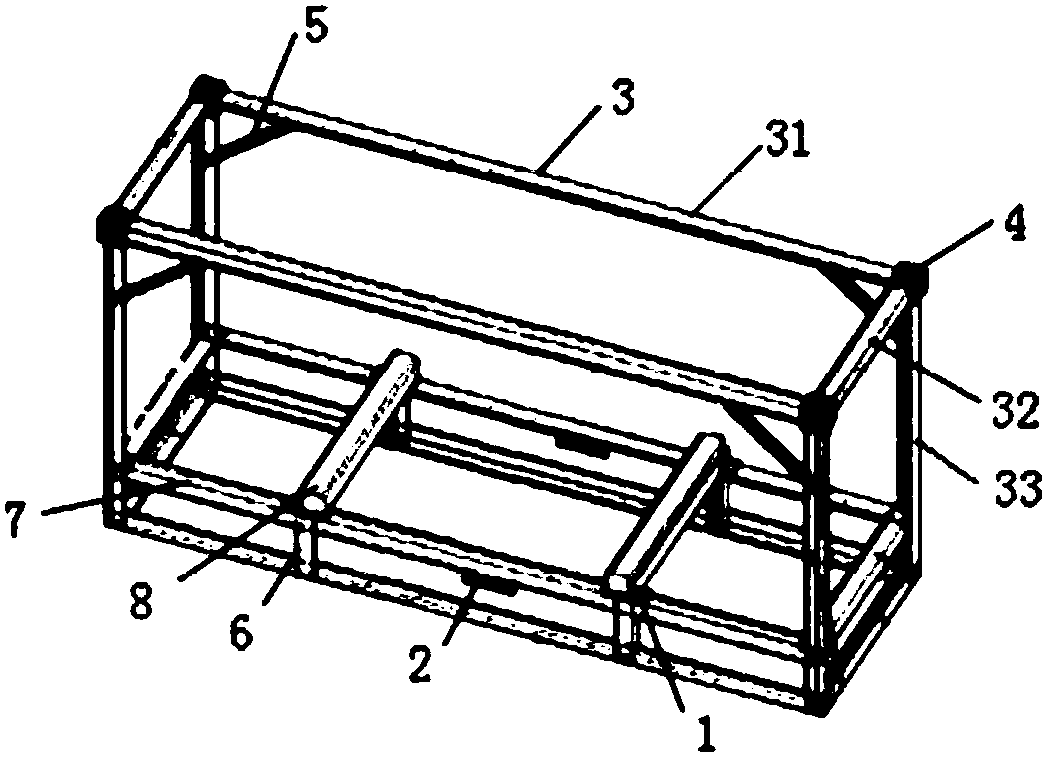

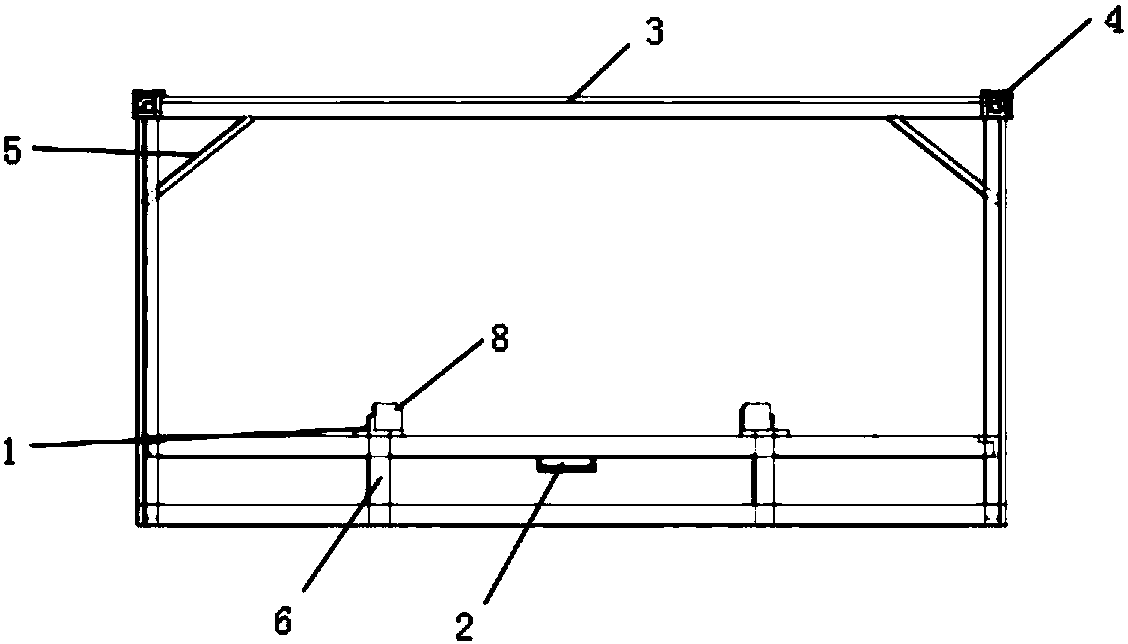

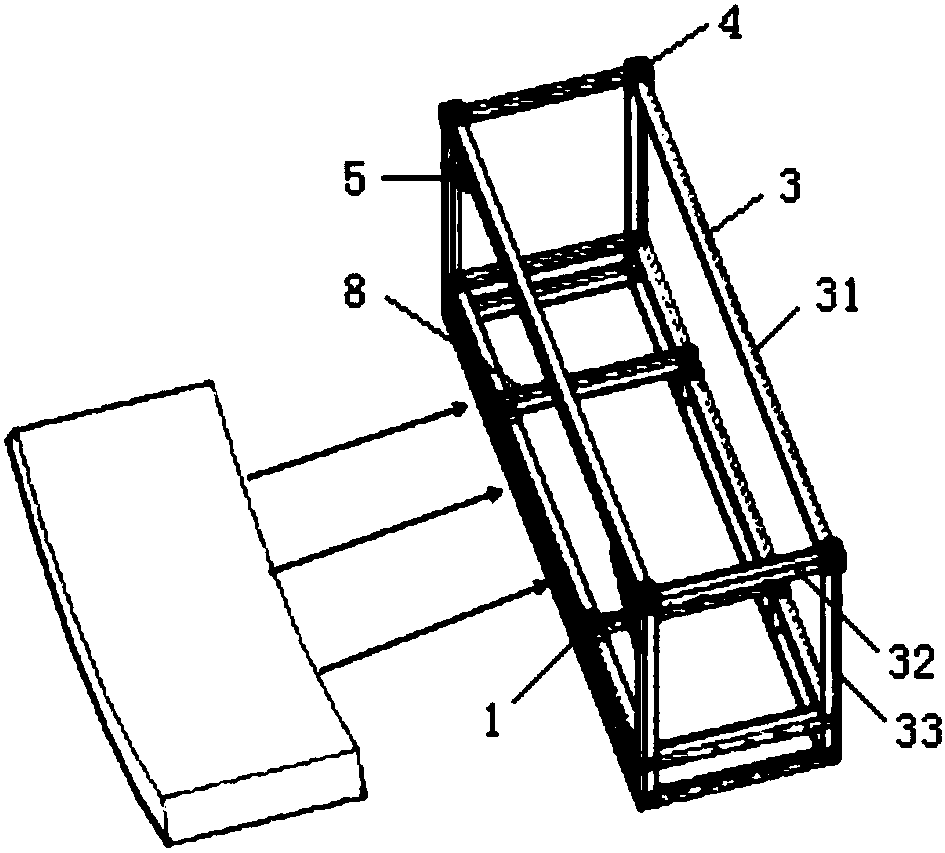

[0023] Such as figure 1 As shown, the segment transport bracket includes a cuboid frame 3 with container-specific lifting lugs 4 on the top around it. The cuboid frame 3 is welded by the first section steel 31, the second section steel 32 and the third section steel 33; The rectangular bracket 7 in the frame 3 is welded by the first steel 31 and the second steel 32; two angle steels 1 are placed in parallel and symmetrically by bolts, and are fixed in the rectangular bracket 7 by bolts; two sleepers 8 is placed on the corresponding angle steel 1; a steel support 6 is fixed vertically below the angle steel 1 to improve the bearing capacity of the bracket; the reinforcing rib 5 is welded on the top of the cuboid frame 3 to increase the overall stability of the frame.

[0024] After the segment is moved laterally onto the bracket by a forklift, the wire rope or binding strap is passed through the buckle 2 on the bracket 7 to fix the segment. The maximum load capacity of the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com