A vertical two-stage blast furnace pulverized coal injection method

A two-stage, pulverized coal technology, applied in blast furnaces, blast furnace details, furnaces, etc., to achieve the effects of increasing coal ratio, improving gas utilization rate, and reducing fuel ratio and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

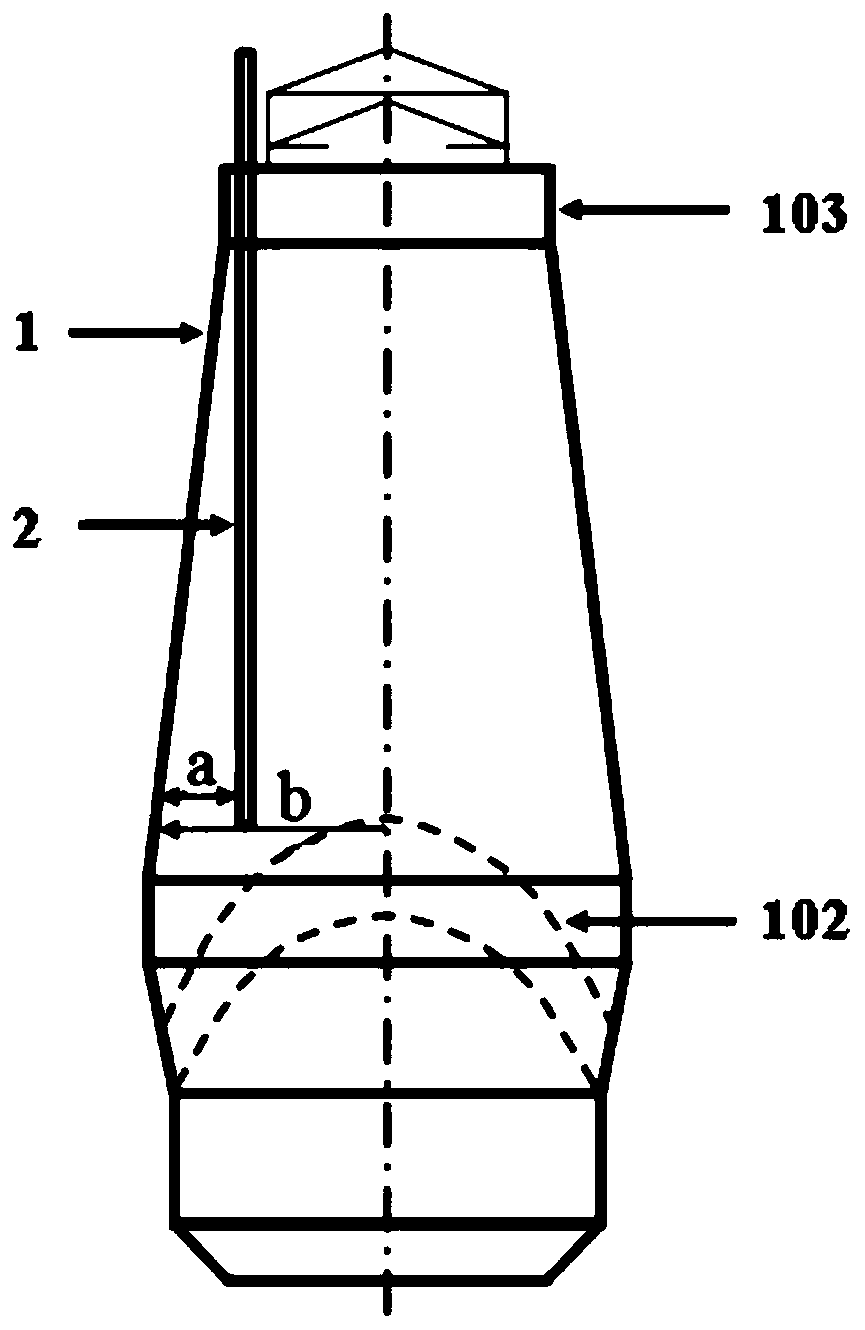

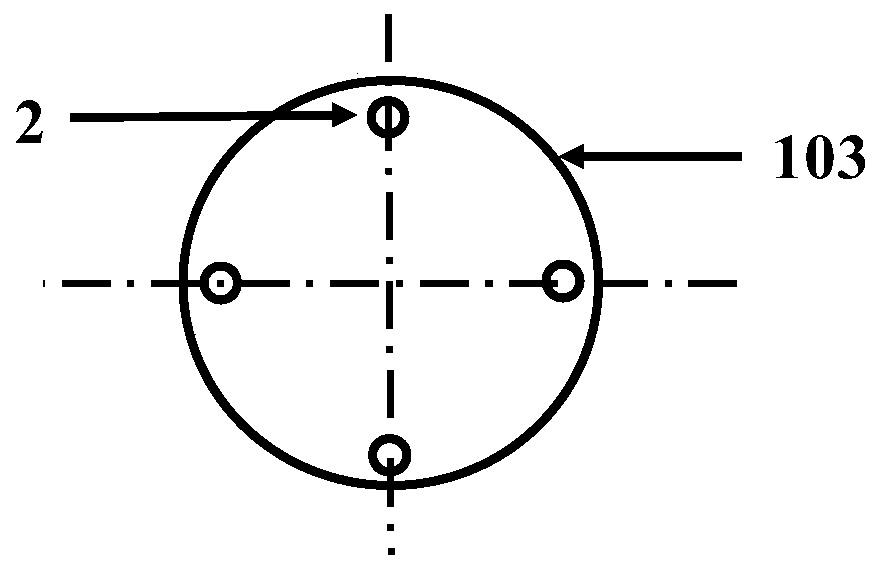

[0038] This embodiment provides a vertical two-stage blast furnace pulverized coal injection method, specifically as follows:

[0039] The pulverized coal is injected into the blast furnace from the outside through a plurality of pulverized coal spray guns from the throat of the blast furnace from top to bottom driven by the high pressure of the carrier gas.

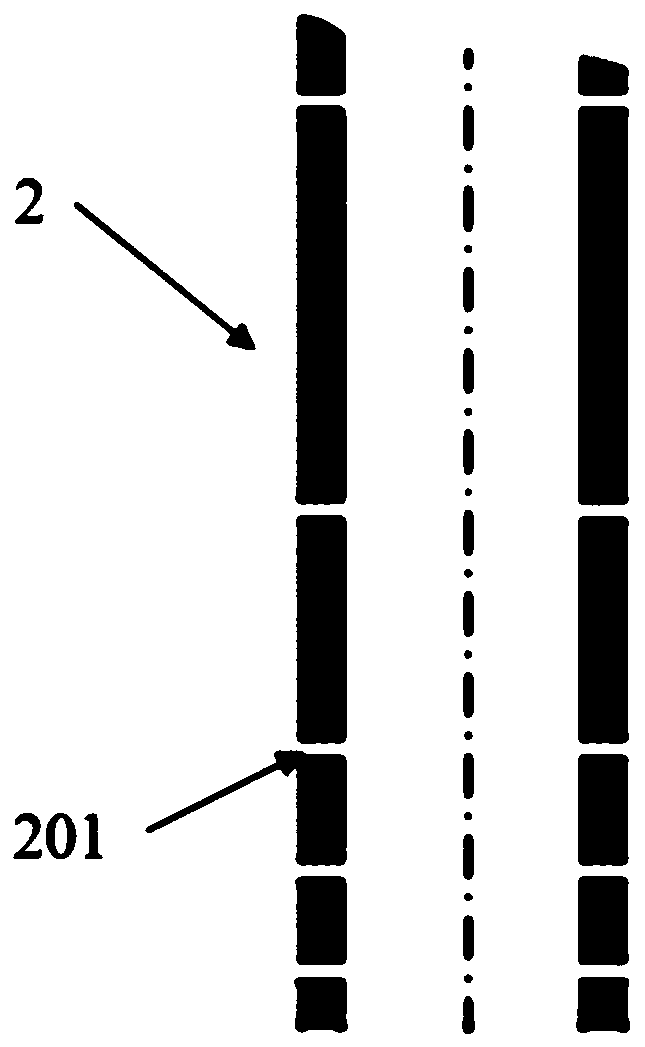

[0040] In this embodiment, the injection amount of the pulverized coal in each pulverized coal spray gun is 3-5 kg / tHM, and the mass ratio of the pulverized coal to the carrier gas is less than or equal to 20 kg / kg.

[0041] The injection pressure P of the pulverized coal at the mouth of the pulverized coal spray gun in this embodiment 喷 , the P 喷 It meets the following mathematical relationship:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com