Design method for 9Ni large forge piece construction forming

A design method and technology for large forgings, applied in the field of forging, can solve the problems of low cost, macrosegregation, coarse central loose grains, and difficulty in guaranteeing metallurgical quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

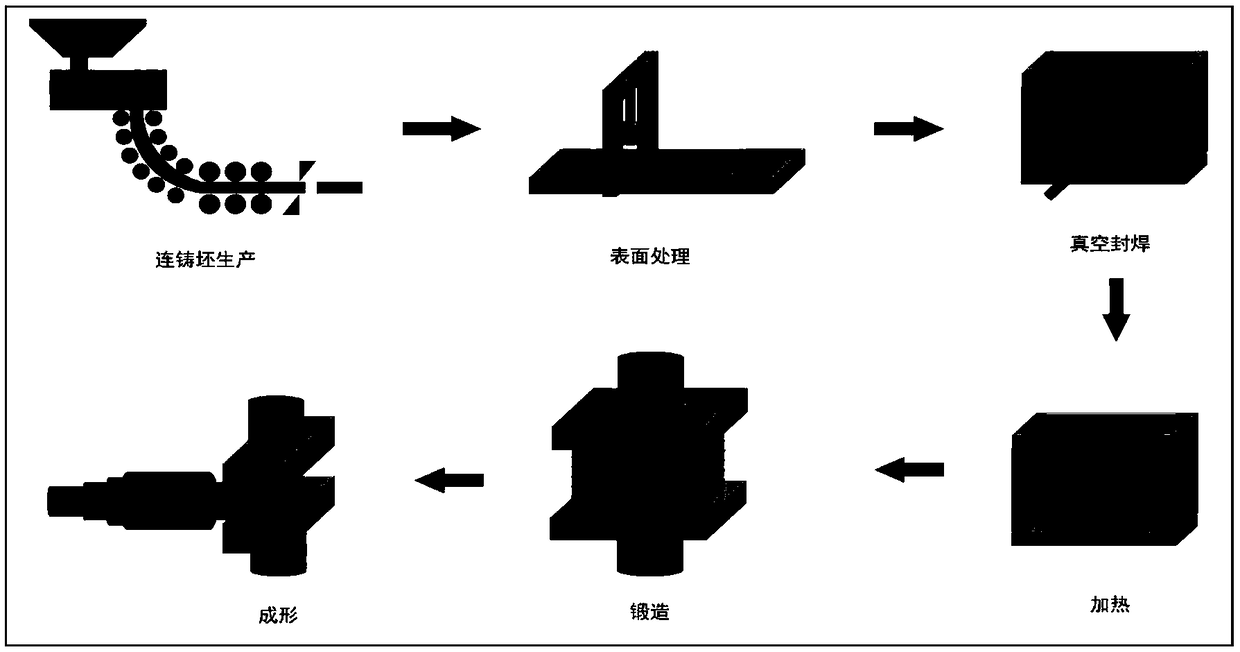

Method used

Image

Examples

Embodiment

[0053] The construction technology of the present invention has been successfully applied in thermal power rotors ( Figure 10 ), tube sheets, large turbine runner shafts and stainless steel support ring forgings for sodium-cooled fast reactors. Such as Figures 11-16 As shown, the manufacturing process of the sodium-cooled fast reactor support ring is constructed by the construction method. It can be seen that the present invention cleans the surface of multiple homogenized base materials and encapsulates them in vacuum, realizes metal solid-state connection under high temperature with large deformation, fully heals the interface, changes the homogeneous preparation technology of large components, and breaks through component manufacturing Limit, improve the quality and reliability of large forgings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com