Cast aluminum alloy material with high strength and high yield-tensile ratio, and preparation method thereof

A technology for casting aluminum alloys and aluminum alloy materials, which is applied in the field of metal materials, can solve the problems of unsatisfactory structural optimization design, low performance of die castings, and hindering the application of alloys, etc., achieve good self-strengthening characteristics, improve mold life, and reduce heat loss. cracking tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

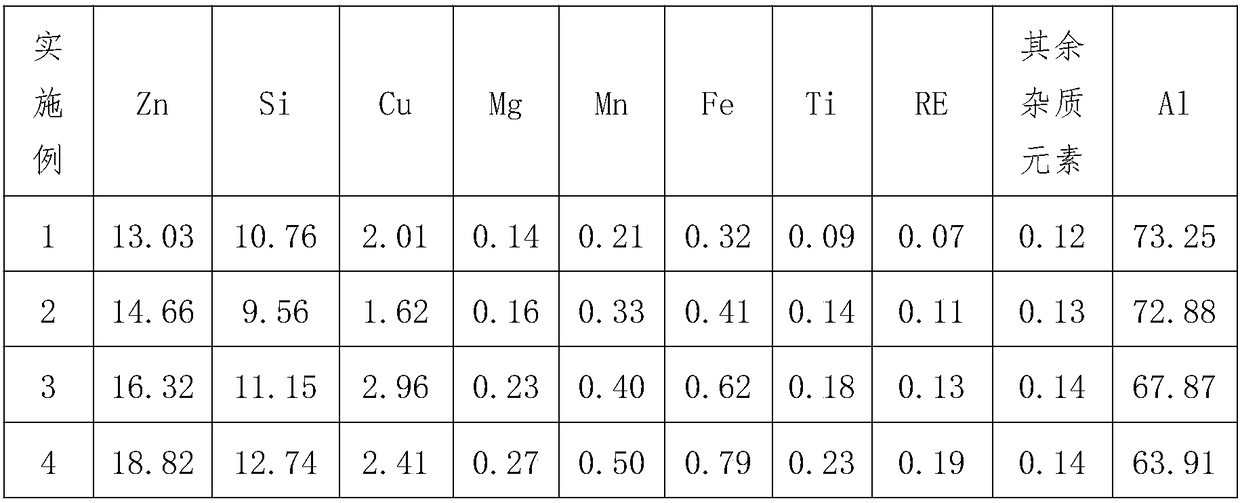

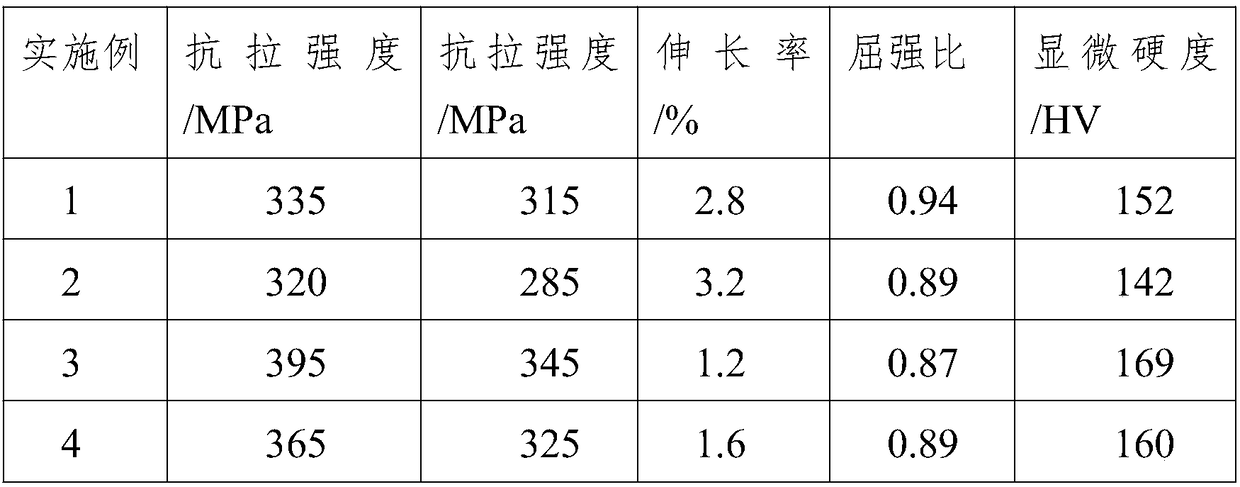

Embodiment 1

[0027] According to the ratio of Al-13.1Zn-10.5Si-2.0Cu-0.15Mg-0.2Mn-0.3Fe-0.1Ti-0.06RE as an example, the mass of raw materials required for 15t alloy is calculated and prepared.

[0028] (1) Clean the furnace and prepare raw materials according to the above composition ratio of the alloy.

[0029] (2) Put the aluminum ingot into the furnace and raise the temperature to 750°C. After the aluminum ingot is completely melted, add the prepared metal Si, red copper and electrolytic manganese into the molten aluminum;

[0030] (3) After the metal is completely melted, cool down to 710°C and add the prepared Zn ingot, Mg ingot and Al-Fe master alloy;

[0031] (4) After the metal is completely melted, adjust the temperature of the molten aluminum to 720°C to keep warm, use a refining spoon to press the special refining agent for aluminum alloy into the melt, and stir it up and down fully, or use high-purity inert gas as a carrier to spray the refining agent into the melt Melt, degas...

Embodiment 2

[0036] According to the ratio of Al-14.8Zn-9.5Si-1.6Cu-0.18Mg-0.3Mn-0.4Fe-0.15Ti-0.10RE as an example, calculate the mass of elemental and master alloy required for 15t alloy, and prepare the materials.

[0037] (1) Clean the furnace and prepare raw materials according to the above composition ratio of the alloy.

[0038] (2) Put the aluminum ingot into the furnace and heat up to 760°C. After the aluminum ingot is completely melted, add the prepared Al-Si master alloy, Al-Cu master alloy and Al-Mn master alloy into the molten aluminum;

[0039] (3) After the metal is completely melted, cool down to 720°C and add the prepared Zn ingot, Mg ingot and Al-Fe master alloy;

[0040] (4) After the metal is completely melted, adjust the temperature of the molten aluminum to 720°C to keep warm, use a refining spoon to press the special refining agent for aluminum alloy into the melt, and stir it up and down fully, or use high-purity inert gas as a carrier to spray the refining agent int...

Embodiment 3

[0045] According to the ratio of Al-16.60Zn-11.0Si-2.9Cu-0.25Mg-0.36Mn-0.6Fe-0.18Ti-0.15RE as an example, the mass of raw materials required for 15t alloy is calculated and prepared.

[0046] (1) Clean the furnace and prepare raw materials according to the above composition ratio of the alloy.

[0047] (2) Put the aluminum ingot into the furnace and raise the temperature to 780°C. After the aluminum ingot is completely melted, add the prepared metal Si, Al-Cu master alloy and electrolytic manganese into the molten aluminum;

[0048] (3) After the metal is completely melted, cool down to 720°C and add the prepared Zn ingot, Mg ingot and Al-Fe master alloy;

[0049] (4) After the metal is completely melted, adjust the temperature of the molten aluminum to 730°C to keep warm, use a refining spoon to press the special refining agent for aluminum alloy into the melt, and stir it up and down fully, or use high-purity inert gas as a carrier to spray the refining agent into the melt Me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com