Autonomous bulldozing robot

A bulldozer and robot technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the randomness and unevenness of filling in the working environment, no autonomous bulldozer robot, etc. problems, to achieve the effect of improving construction quality, avoiding omissions, and accurate autonomous navigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The technology and method of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. The following examples and drawings are used to illustrate the technical structure of the present invention, but are not intended to limit the scope of the present invention.

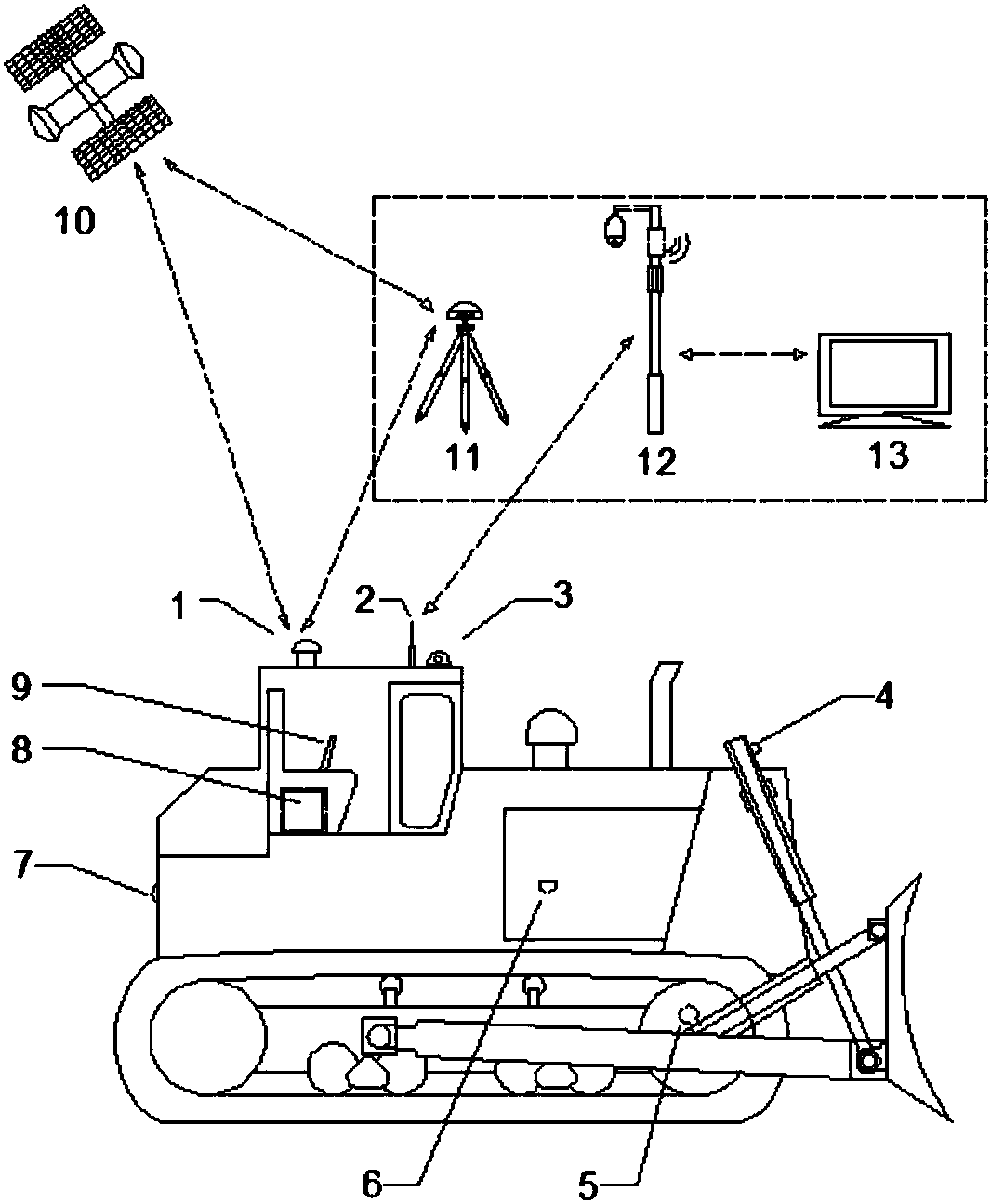

[0065] figure 1 Shown is a structural diagram of an embodiment of the invention applicable to a bulldozing robot, which mainly includes a bulldozer, a bulldozer-borne autonomous measurement and control device, a remote scheduling management device, and a satellite positioning device.

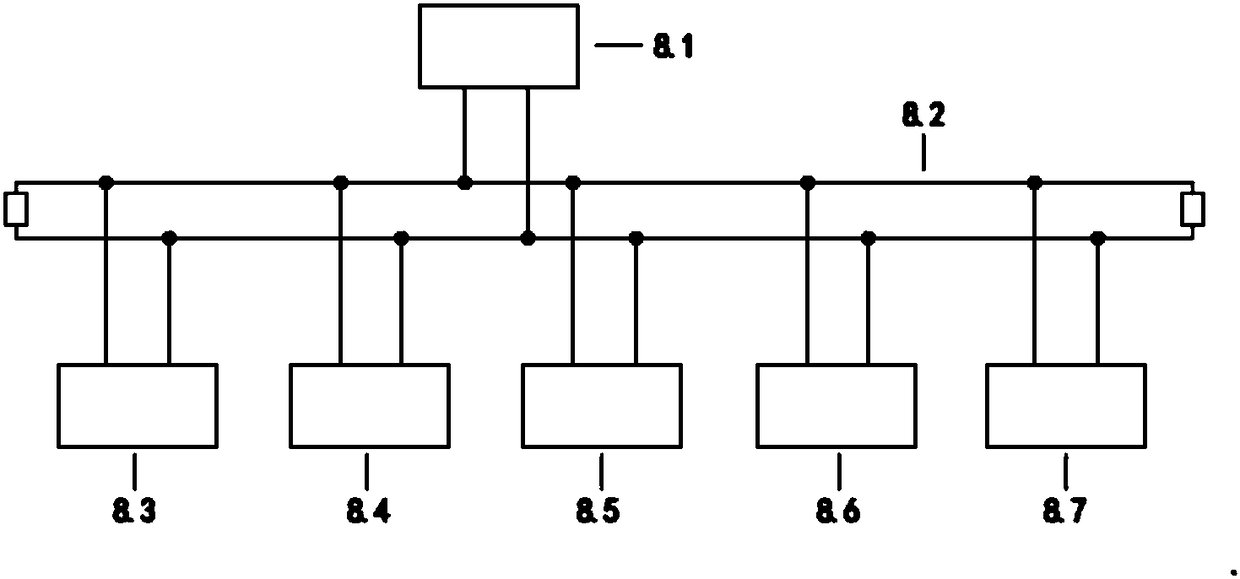

[0066] The bulldozer-borne autonomous measurement and control device includes satellite positioning receiver group 1, communication transceiver antenna 2, camera pair 3, blade lift sensor 4, blade tilt sensor 5, engine speed control driver 6, reversing collision avoidance radar 7, integrated controller 8 and Travel electromagnetic drive 9;

[0067] The rem...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap