A new type of support isolation structure and its installation method

A seismic isolation and bearing technology, applied in the direction of earthquake resistance, building type, building components, etc., can solve the problems of difficult installation, easy aging of components, poor seismic isolation effect, etc., to avoid excessive pressure and good seismic isolation effect. , the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

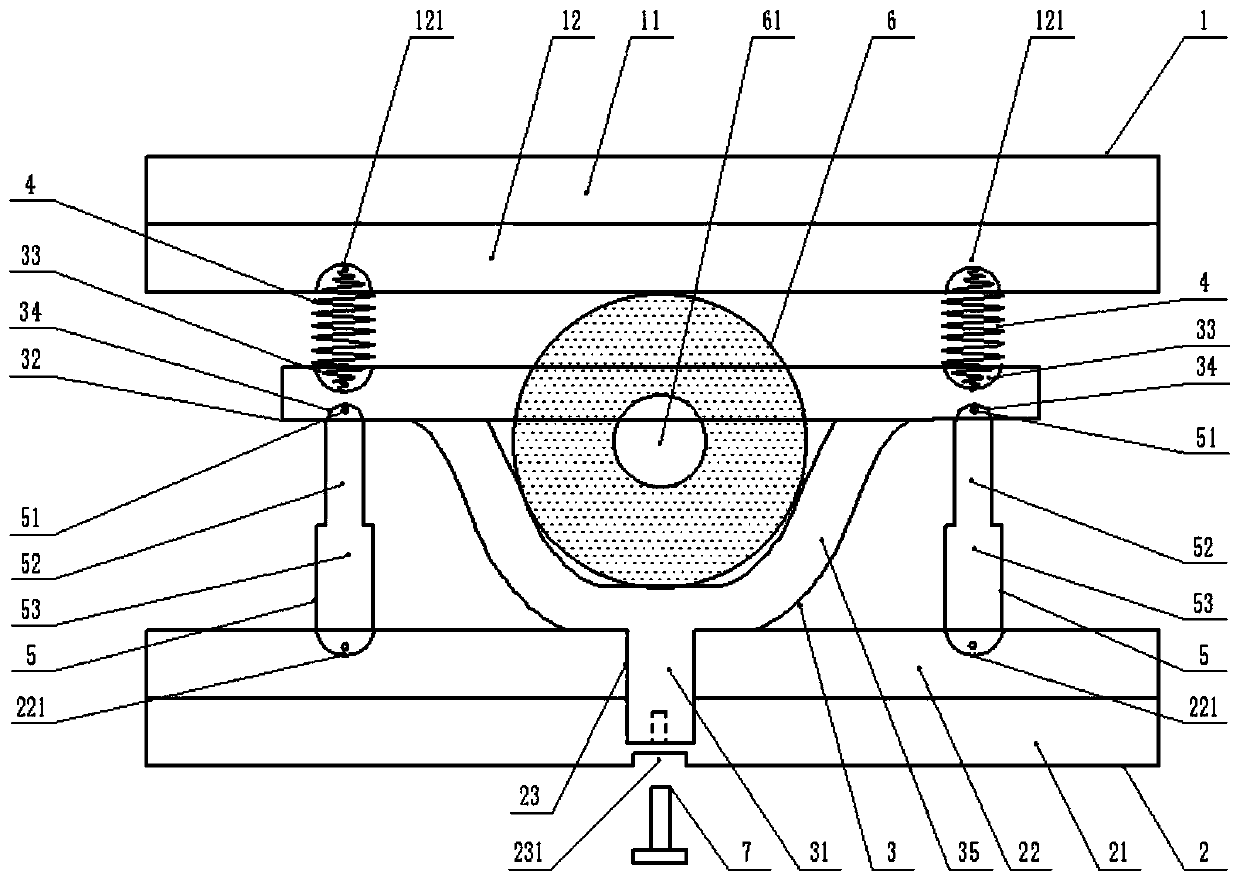

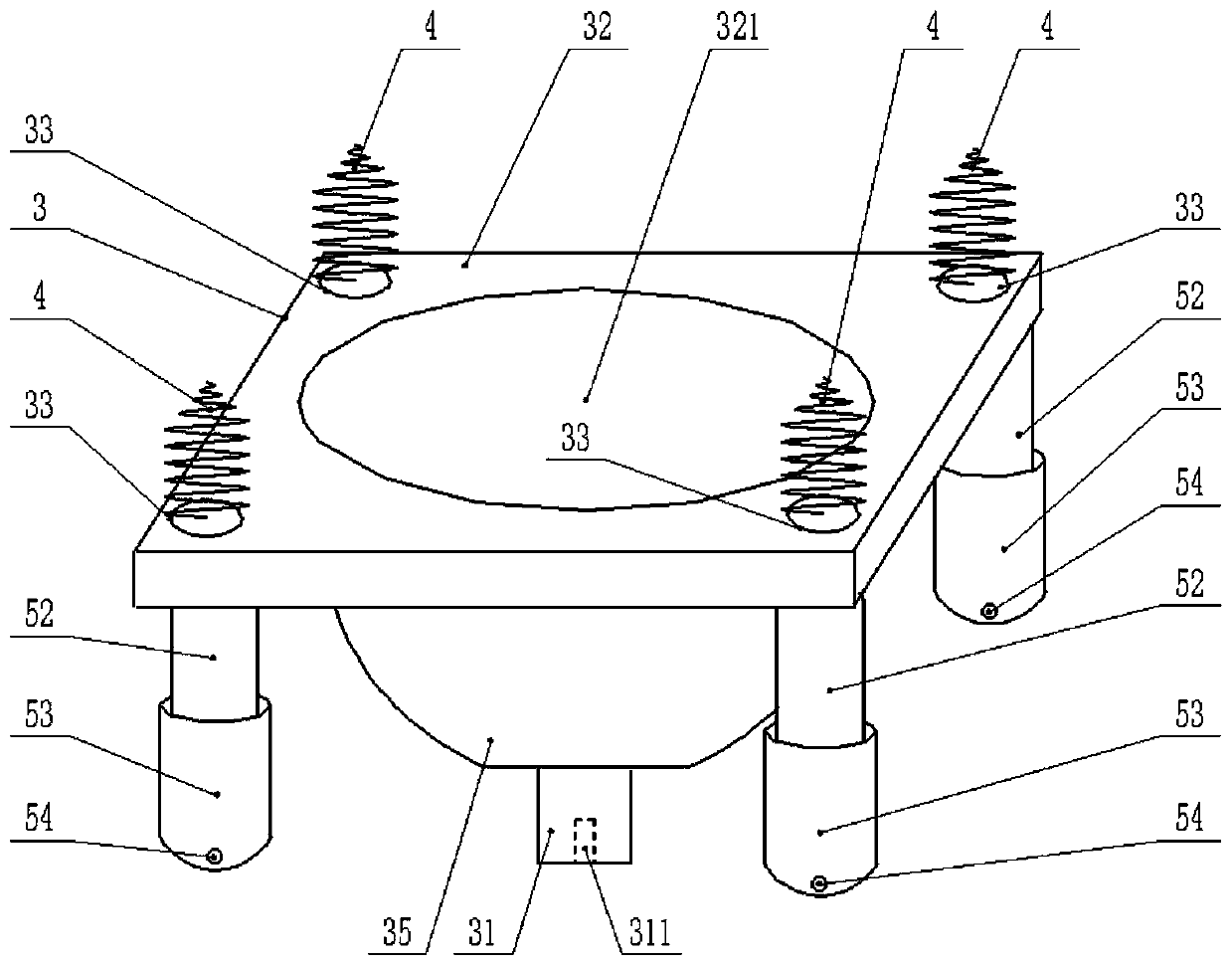

[0029] Such as Figure 1-2As shown, a new type of support isolation structure mainly includes a top plate 1, a bottom plate 2, a shock isolation member 3 and an elastic ball 6. The top plate 1 is divided into two layers, the upper layer is a fireproof layer-11, the lower layer is a steel plate-12, and the steel plate Spring fixing holes 121 are arranged at the four vertices of the lower surface of —12; the vibration isolation member 3 is arranged below the top plate 1, and the vibration isolation member 3 includes a fixed rod 31, an upper panel 32 and a groove 35, and the upper panel 32 is arranged on the vibration isolation unit. On the upper surface of the component 3, a circular hole 321 is provided at the center of the upper panel 32, the groove 35 is hemispherical and the mouth of the groove 35 is fixedly connected below the circular hole 321, and the four corners of the upper surface of the upper panel 32 are respectively provided with springs to fix Hole 2 33, spring fi...

Embodiment 2

[0031] Such as Figure 1-2 As shown, a new type of support isolation structure mainly includes a top plate 1, a bottom plate 2, a shock isolation member 3 and an elastic ball 6. The top plate 1 is divided into two layers, the upper layer is a fireproof layer-11, the lower layer is a steel plate-12, and the steel plate The lower surface of —12 is in a square matrix and is provided with spring fixing holes —121; the vibration isolation member 3 is arranged under the top plate 1, and the vibration isolation member 3 includes a fixed rod 31, an upper panel 32 and a groove 35, and the upper panel 32 is arranged on the vibration isolation unit. On the upper surface of the member 3, the upper panel 32 has a circular hole 321, the groove 35 is hemispherical and the mouth of the groove 35 is fixedly connected with the circular hole 321, and the four corners of the upper surface of the upper panel 32 are respectively provided with two spring fixing holes. 33. Spring fixing hole 2 33 cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com