Wall space troweling machine

A plastering machine and ash block technology, which is applied in the direction of construction and building construction, can solve the problems of easy falling off of slurry, low quality and efficiency of plastering, and easy overflow of slurry, etc., so as to improve the efficiency and effect of plastering , reduce the spalling of gray materials, and improve the effect of plastering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

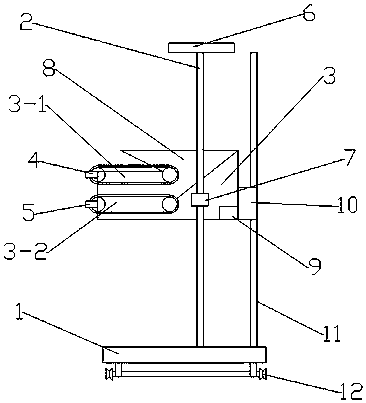

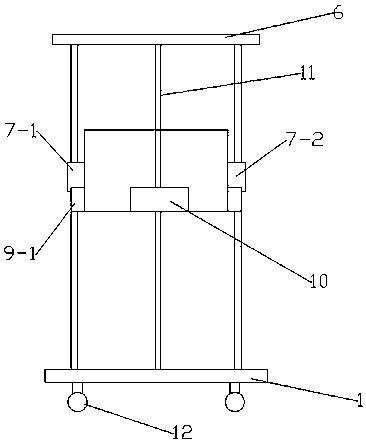

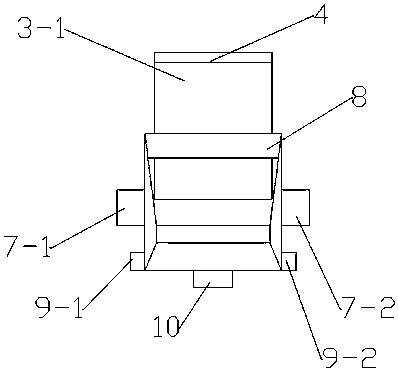

[0026] A wall plastering machine, mainly comprising a frame 1, a transmission rod 2, and a plastering device 3, characterized in that: the plastering device 3 contains two plastering conveyor belts, respectively No. 1 plastering conveyor belt 3-1 and No. 2 plastering conveyor belt 3-2, No. 1 plastering conveyor belt 3-1 front end with No. 1 plastering block 4, No. 2 plastering conveyor belt 3-2 with No. 2 plastering block 5, No. 1 plastering block 4 And No. 2 plastering block 5 has a heating function; wherein the upper end of the device is a limit frame 6, and the lower end of the limit frame 6 is a transmission rod 2, and the transmission rod 2 is connected with the plastering device 3 through the transmission device 7, and the plastering device 3 There is a feeding port 8, there is a transmission motor 9 under the feeding port 8, the right end of the transmission motor 9 is a fixing device 10, the fixing device 10 is fixed on the fixed frame 11, and the left end of the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com