Active and semi-active electromagnetic vibration suppression system

An electromagnetic vibration, semi-active technology, applied in vibration suppression adjustment, non-rotation vibration suppression, spring/shock absorber, etc., can solve problems such as no data collected, no explanation or report found, etc., to achieve rich functions and save power The effect of resources, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

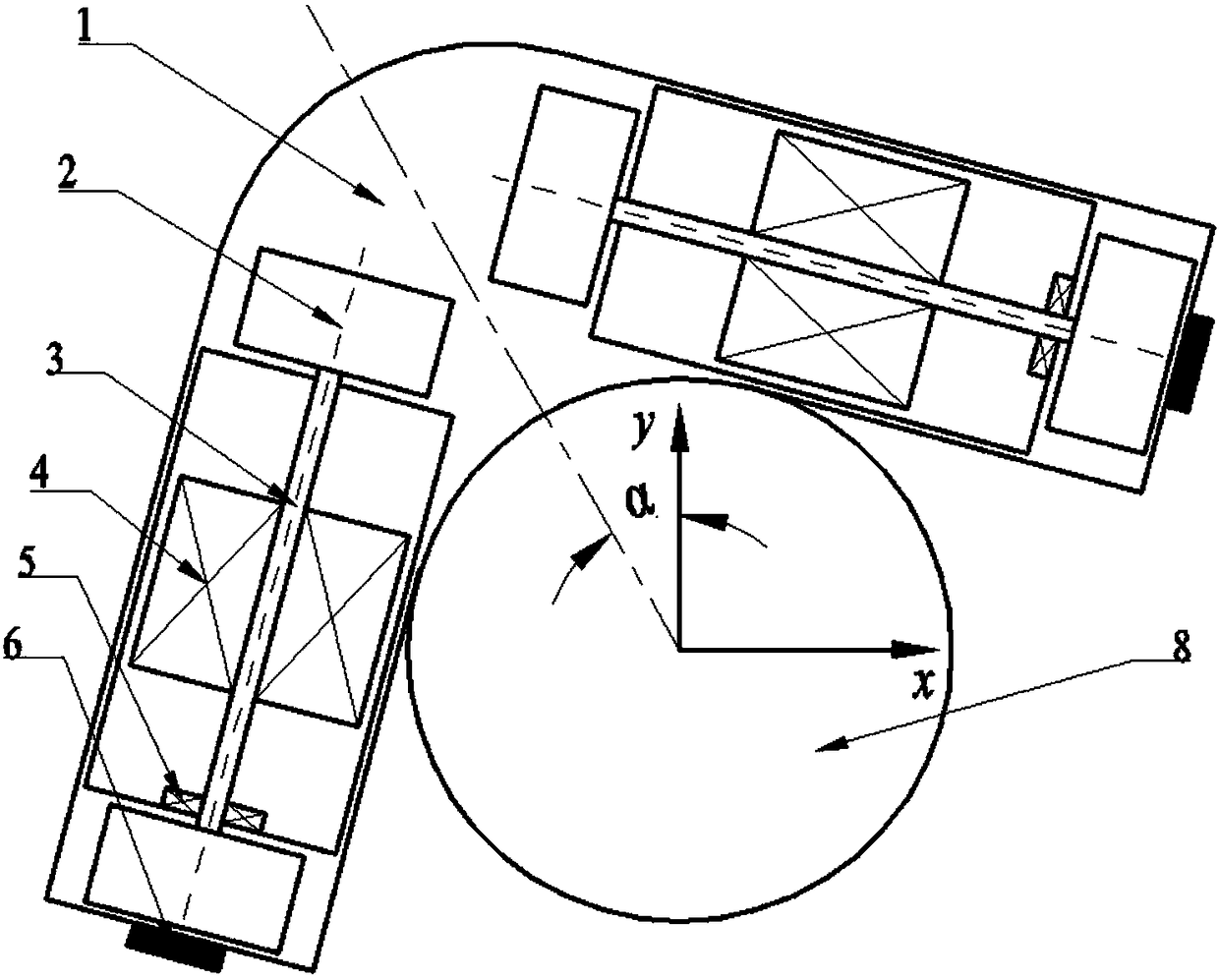

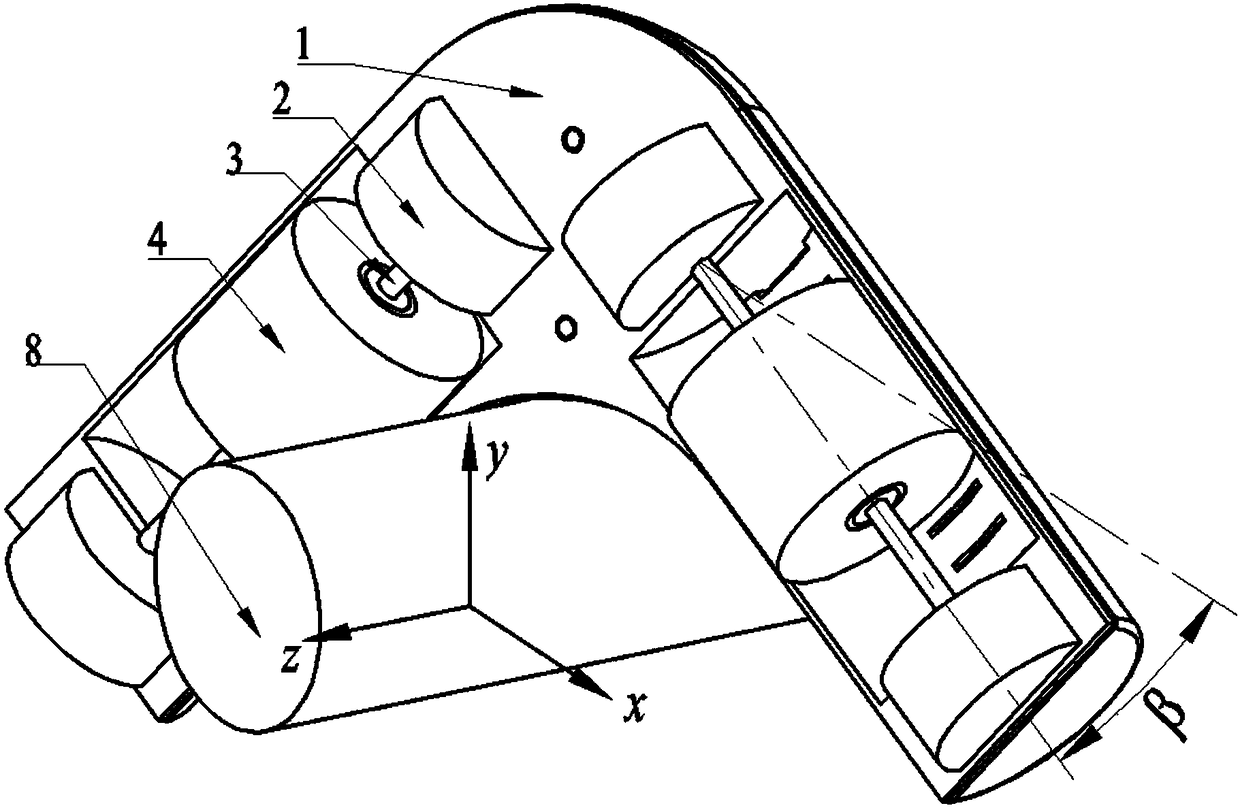

[0060] figure 2 is a modification based on the basic embodiment. The vibration suppression device is deflected by a certain angle β around the y-axis. Since the electromagnetic spring also has a stiffness component in the z-direction, the vibration in the 8-axis direction of the isolated object can also be suppressed, so that the device can decompose the vibration from any direction in space. Vibration suppression is performed for the three directions of x, y, and z.

specific Embodiment 2

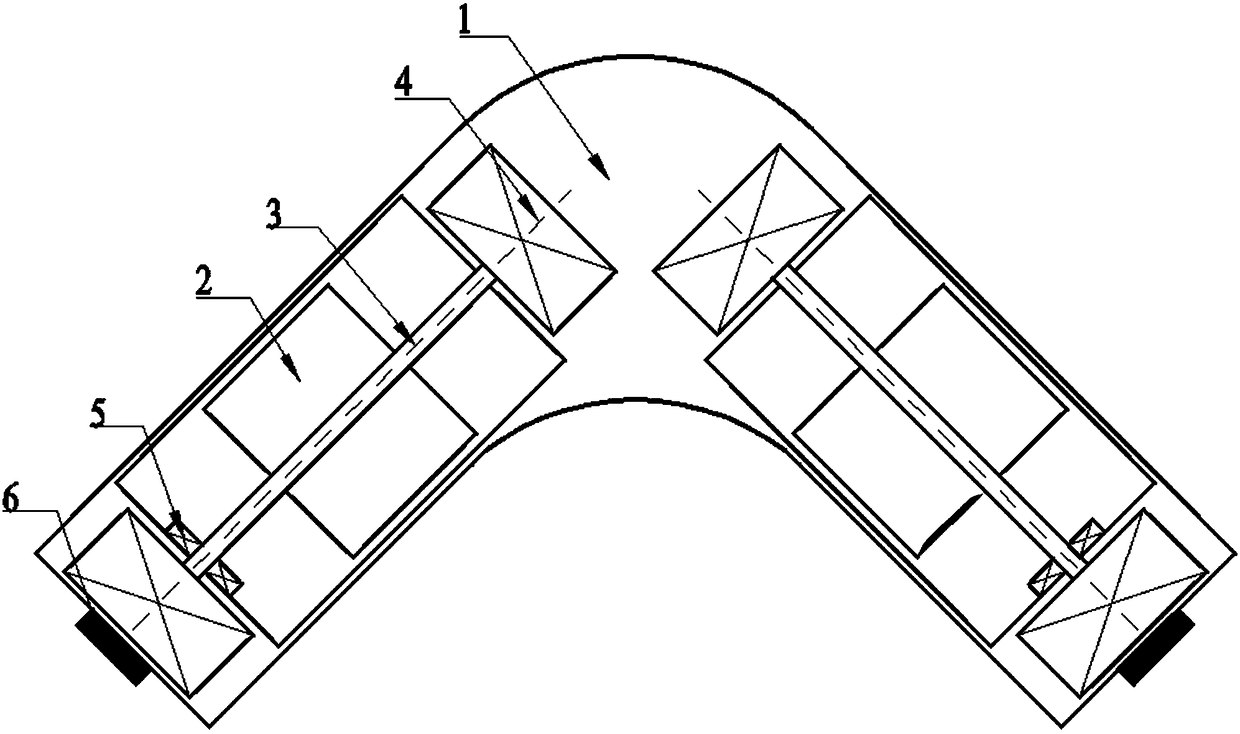

[0062] image 3 It is a semi-active electromagnetic vibration suppression combination device for permanent magnet movement, similar to the basic embodiment, but the positions of the electromagnetic coil 4 and the permanent magnet 2 are interchanged, the electromagnetic coil is fixed, and the permanent magnet 2 can slide freely on the shaft and connect with the energized electromagnetic coil 4 forms an electromagnetic spring, and the driving principle is similar to that of the basic embodiment, except that the induced voltage in the magnetoelectric sensor 5 is generated by the motion of the permanent magnet.

specific Embodiment 3

[0064] Figure 4 It is a deformation of the specific embodiment 2, and it is also a semi-active electromagnetic vibration suppression combination device for permanent magnet movement. The difference is that there are only two symmetrically arranged electromagnetic coils 4 in the device, and the permanent magnet 2 is sleeved in the electromagnetic coil 4. There is a small gap with the inner wall of the electromagnetic coil 4, so that the permanent magnet can move in the axial direction. After the electromagnetic coil 4 is energized, an electromagnetic spring is formed between the electromagnetic coil 4 and the permanent magnet. The permanent magnet can be a whole permanent magnet or a plurality of permanent magnets spliced together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com