Gas stove windproof combustor

A technology of burners and gas furnaces, applied in the field of gas furnaces, can solve the problems of reducing work efficiency and quality, reducing the service life of ignition switches, and increasing use costs, so as to achieve the effects of improving work quality, preventing combustion, and saving use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

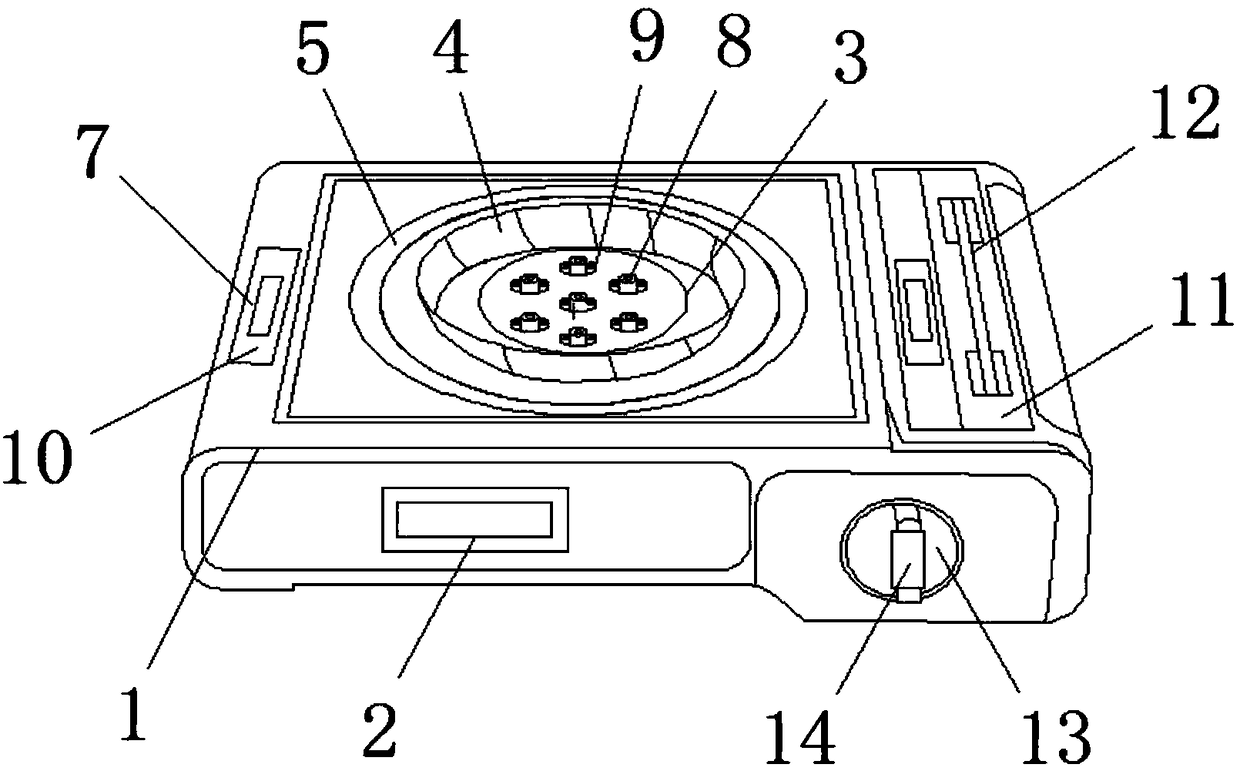

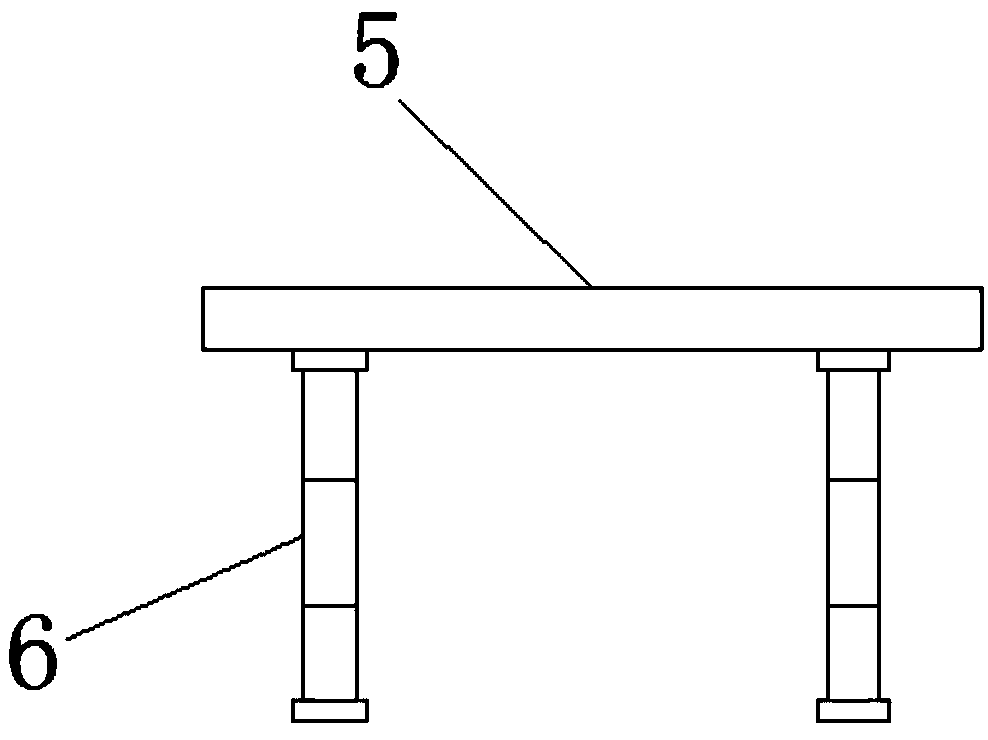

[0019] see Figure 1-Figure 2 , the present invention provides a windproof burner for a gas stove, comprising a casing 1, a controller 2 is arranged outside the casing 1, the controller 2 and the casing 1 are embedded and fixedly connected, and the casing 1 is internally provided with a The combustion seat 3 is provided with a support seat 4 on the outside of the combustion seat 3, and a wind shield 5 is arranged outside the support seat 4, and the wind shield 5 is located inside the casing 1. The wind shield 5 and the casing 1 for sliding connection, the upper surface of the windshield 5 is in an arc shape, the lower part of the windshield 5 is provided with a hydraulic rod 6, the windshield 5 and the hydraulic rod 6 are fixedly con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap