LCD (liquid crystal display) quality check method and device, CIM (computer integrated manufacturing) system and computer storage medium

A computer storage and quality inspection technology, applied in the field of LCD quality inspection, can solve the problems of easy misjudgment and other problems, achieve the effect of improving the detection rate, saving labor and time costs, and reducing the misjudgment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

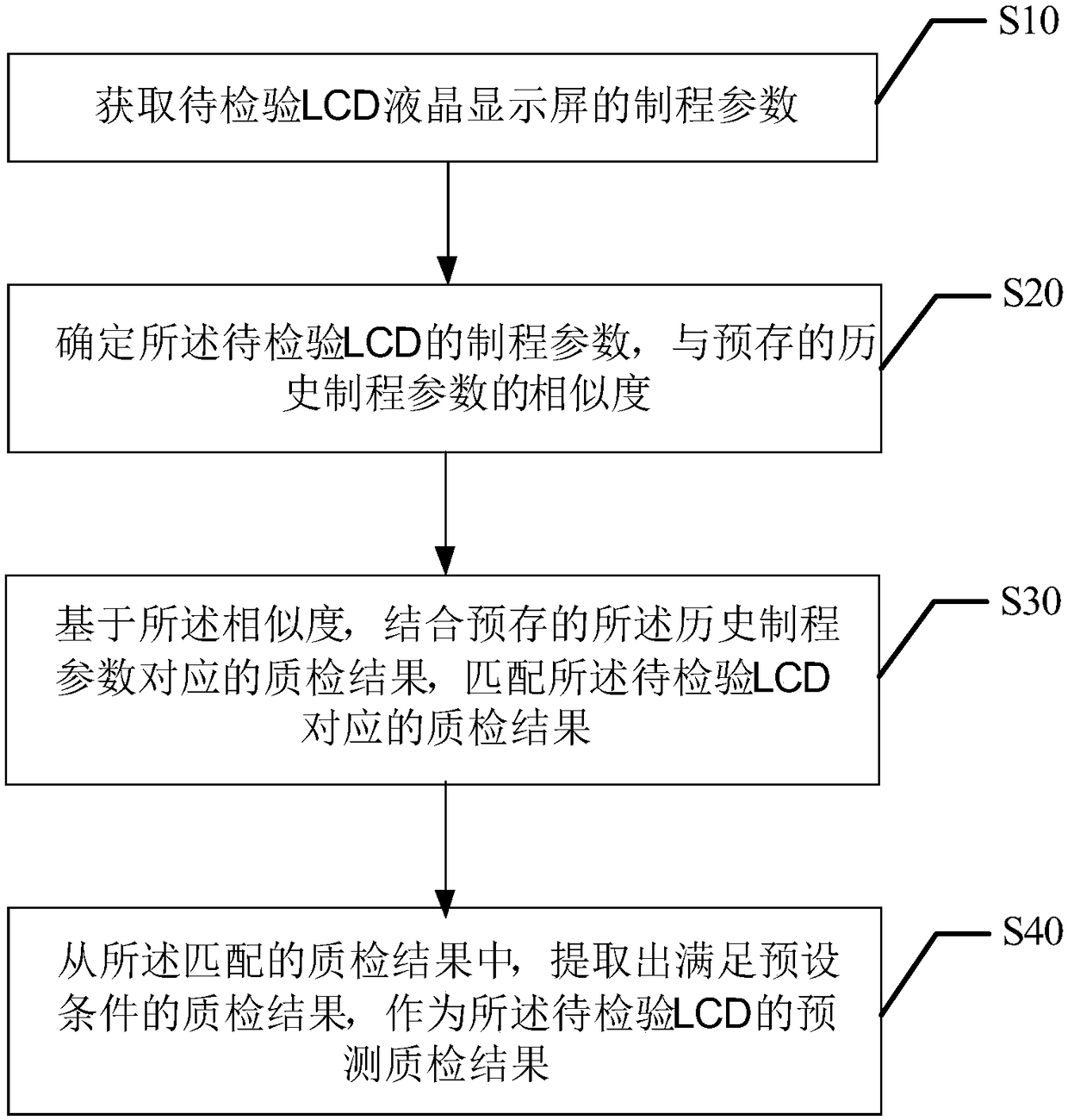

[0039] The main solutions of the embodiments of the present invention are: to obtain the process parameters of the LCD to be inspected; to determine the similarity between the process parameters of the LCD to be inspected and the pre-stored historical process parameters; based on the similarity, combined with the pre-stored The quality inspection results corresponding to the historical process parameters are matched with the quality inspection results corresponding to the LCD to be inspected; from the matched quality inspection results, the quality inspection results that meet the preset conditions are extracted as the LCD to be inspected predicted quality inspection results.

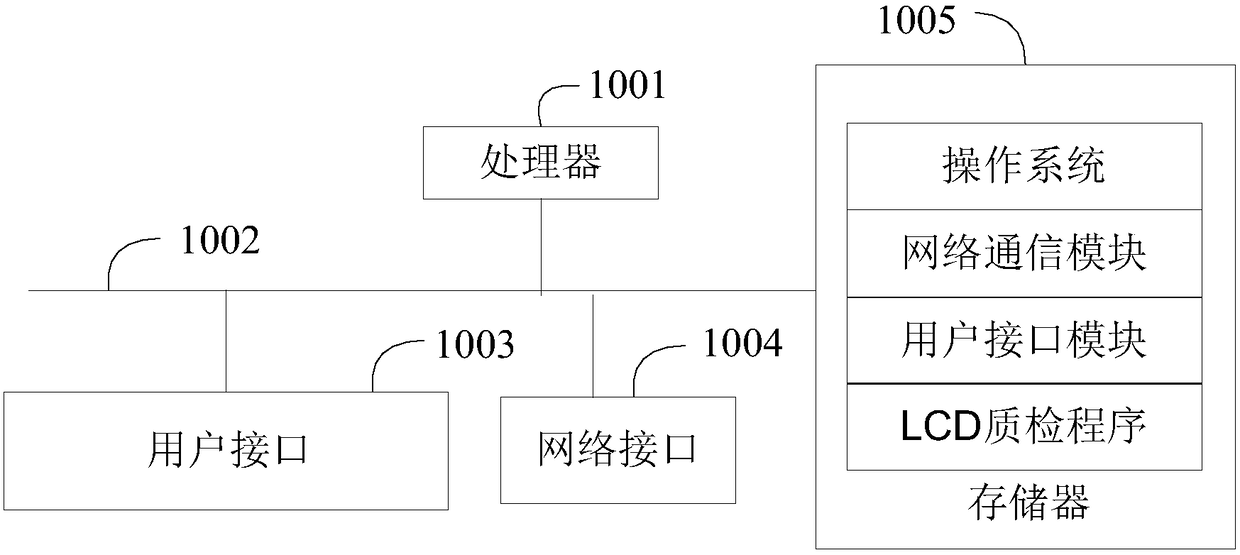

[0040] Such as figure 1 as shown, figure 1 It is a schematic diagram of the structure of the terminal to which the device of the hardware op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com