Chip package substrate and chip package structure

A chip packaging structure and chip packaging technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as electrical short circuits, and achieve the effects of avoiding electrical short circuits, good quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

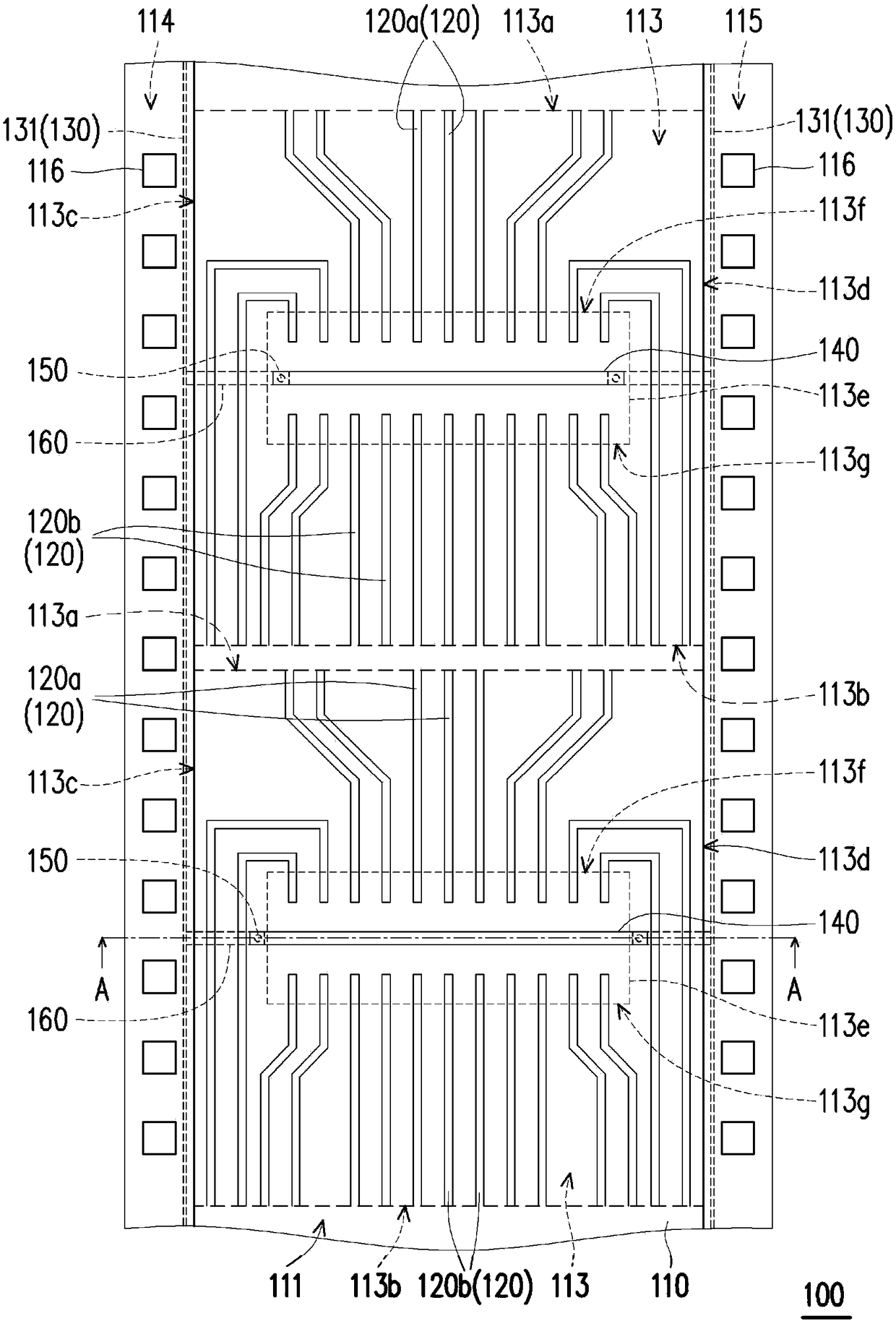

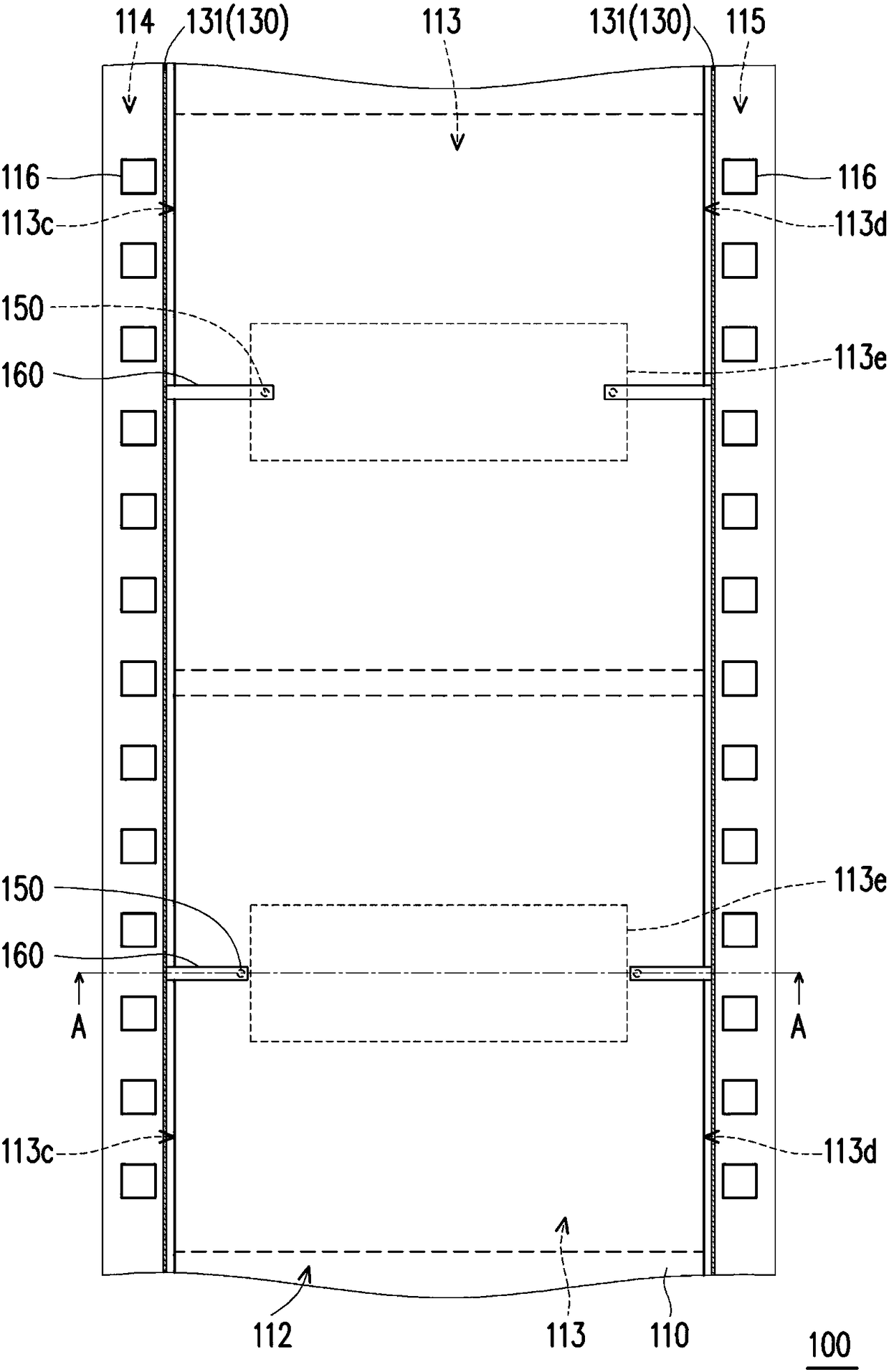

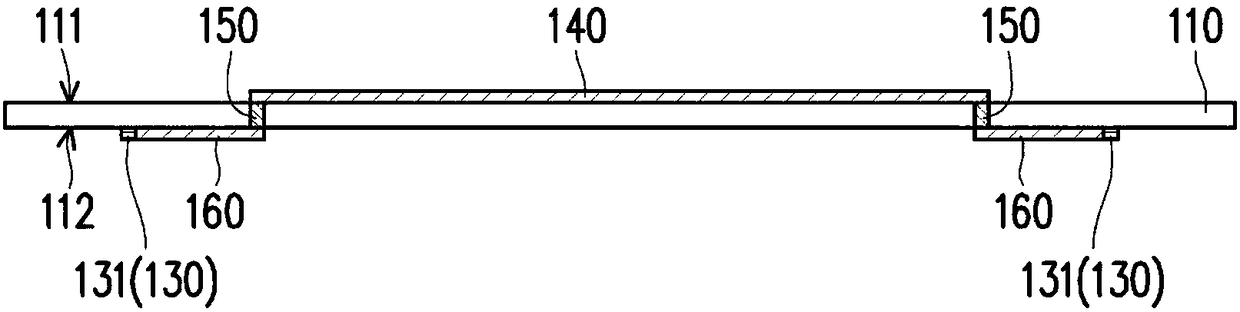

[0047] figure 1 It is a schematic partial top view of a chip package substrate according to an embodiment of the present invention. figure 2 yes figure 1 A partial bottom view of the chip package substrate. image 3 yes figure 1 The schematic cross-sectional view of the chip packaging substrate along the line segment A-A, where image 3 Some pins are omitted from the illustration. Please refer to Figure 1 to Figure 3 , in this embodiment, the chip packaging substrate 100 includes a flexible film 110, a plurality of pins 120, a conductive layer 130, a plurality of first lines 140, a plurality of conductive members 150 and a plurality of second lines 160, wherein The material of the flexible film 110 can be polyimide (PI) or polyester resin (PET), and has a first surface 111 and a second surface 112 opposite to each other, a plurality of packaging areas 113 and the The transmission areas 114 and 115 on opposite sides. The pins 120 are disposed on the first surface 111 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com