Brush retainer for motor

A retainer and brush technology, which is applied in the direction of current collectors, rotating current collectors, circuits, etc., can solve the problems of low accuracy and achieve the effects of reducing noise formation, improving commutation accuracy, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

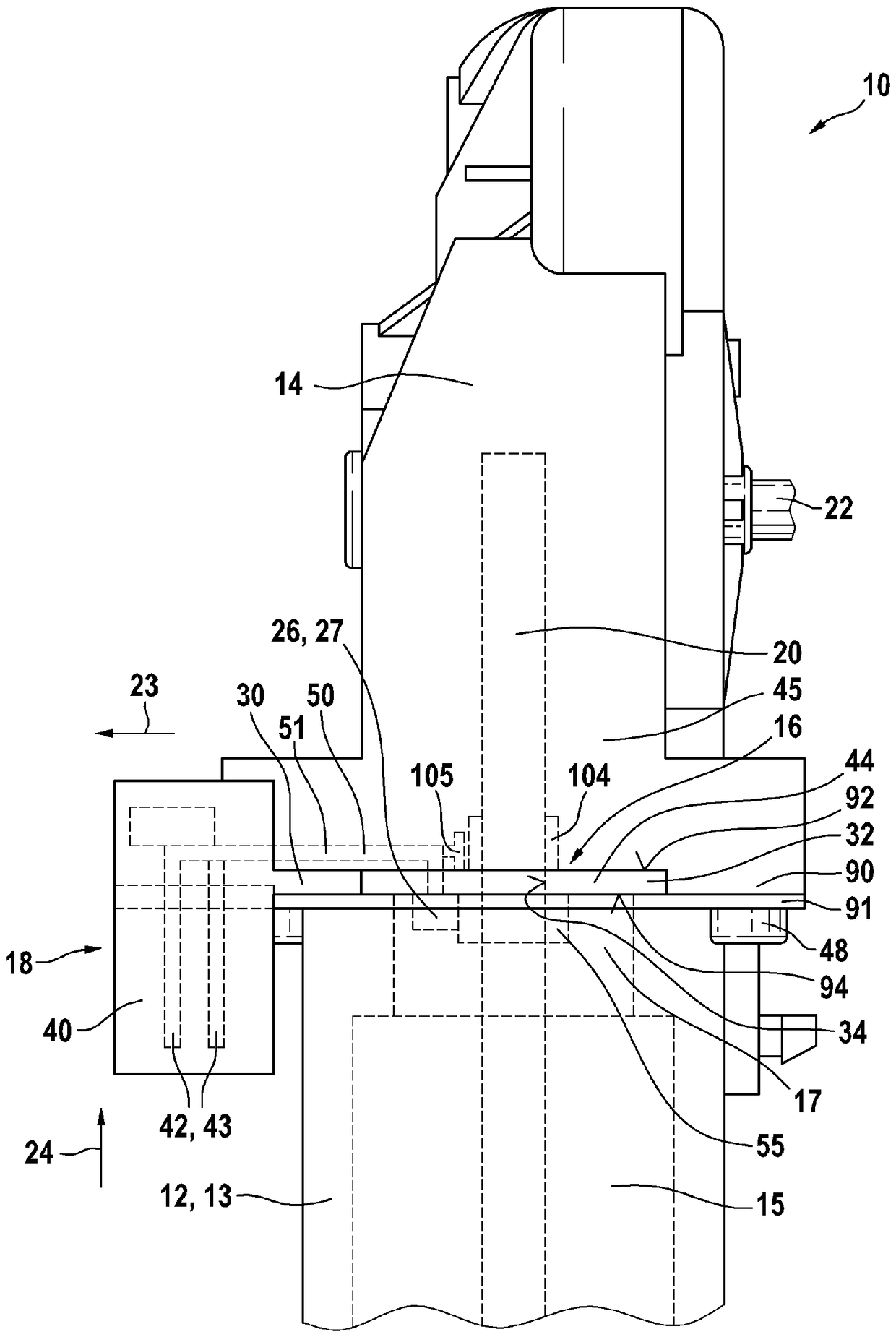

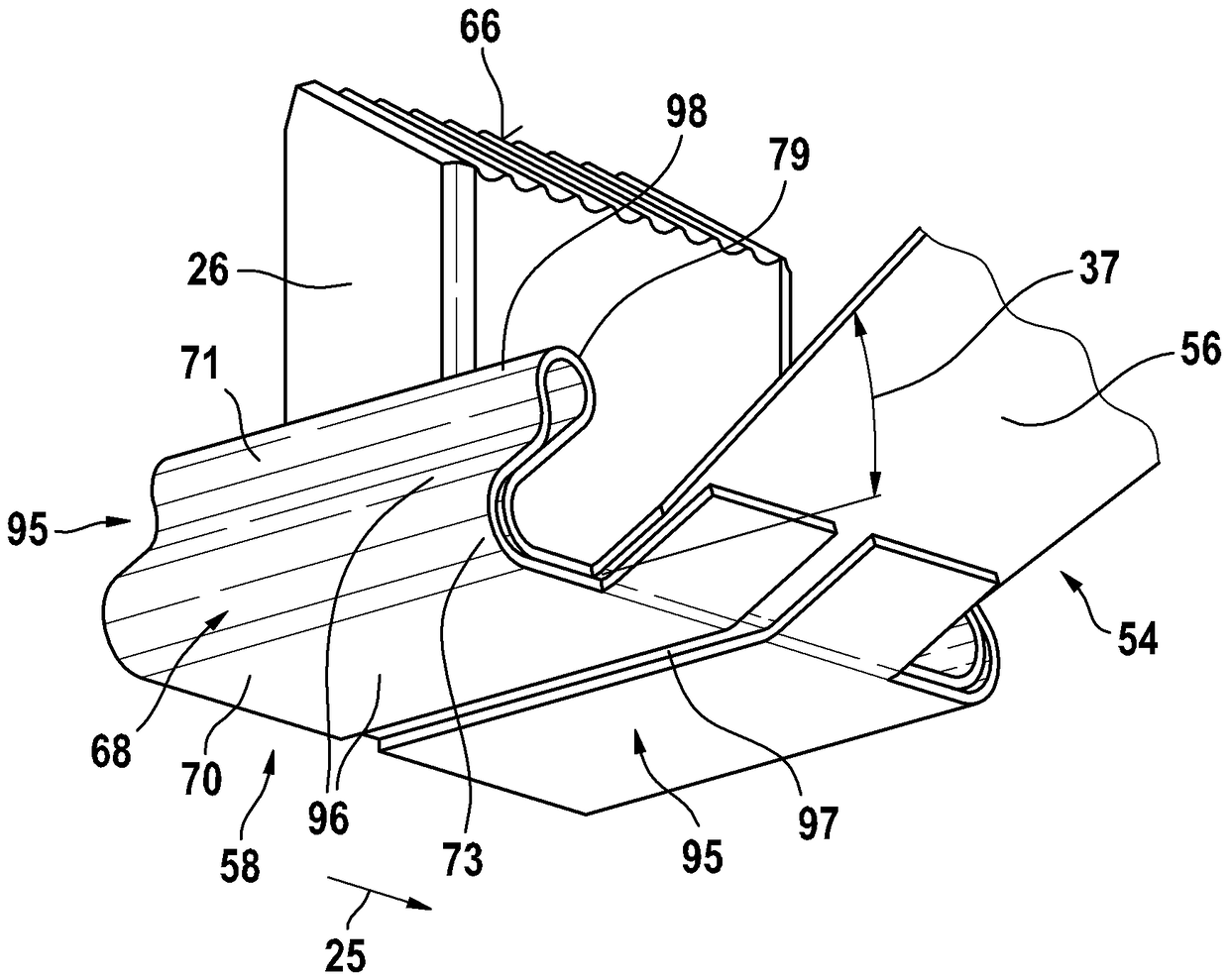

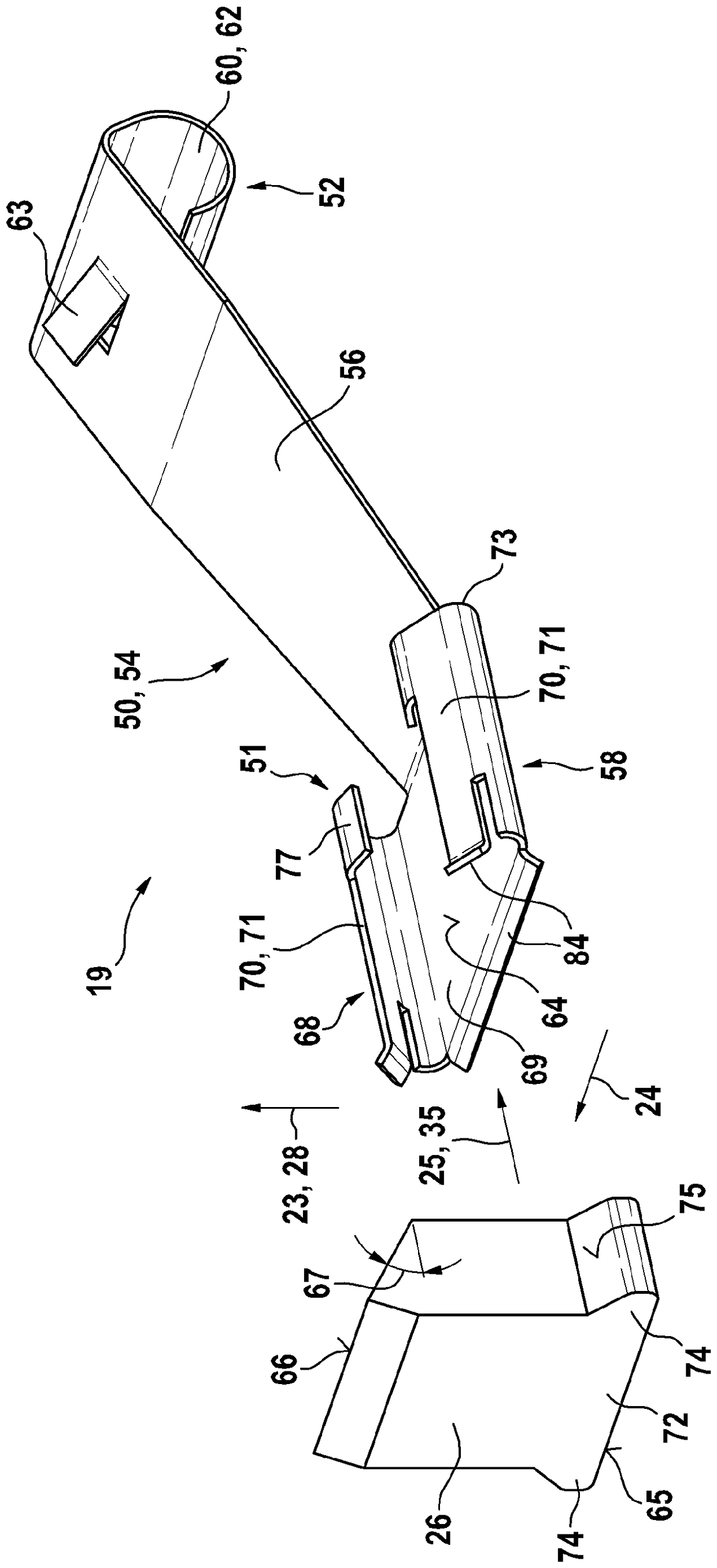

[0025] figure 1 The electric motor 10 is shown, as it is used, for example, to adjust movable components in a motor vehicle, preferably a window pane, a sunroof or seat components. In this case, a stator 13 is arranged in the pole shoe 12 , inside which a rotor 15 is arranged, the rotor shaft 20 of which extends in the axial direction 24 from the pole shoe 12 into the axially adjoining gear housing 14 . In this case, the drive torque of the rotor shaft 20 is transmitted to a transmission arranged in the transmission housing 14 , which has an output element 22 which cooperates with a mechanism not shown, which The resulting mechanism moves, for example, parts of a vehicle seat or a window pane in a motor vehicle. In the axial direction 24 , between the pole piece 12 and the transmission housing 14 is arranged a plug-in module 16 , which is electrically connected to the brushes 26 of the brush carrier component 17 for electrical contacting arranged on the rotor shaft 20 The comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com