Pumps for temperature circulation circuits in automobiles

A temperature cycle and loop technology, which is applied to the components, pumps, and pump devices of pumping devices for elastic fluids, can solve the problems of surface pressure wear, loss, high surface compressive stress, etc., and achieve a compact structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

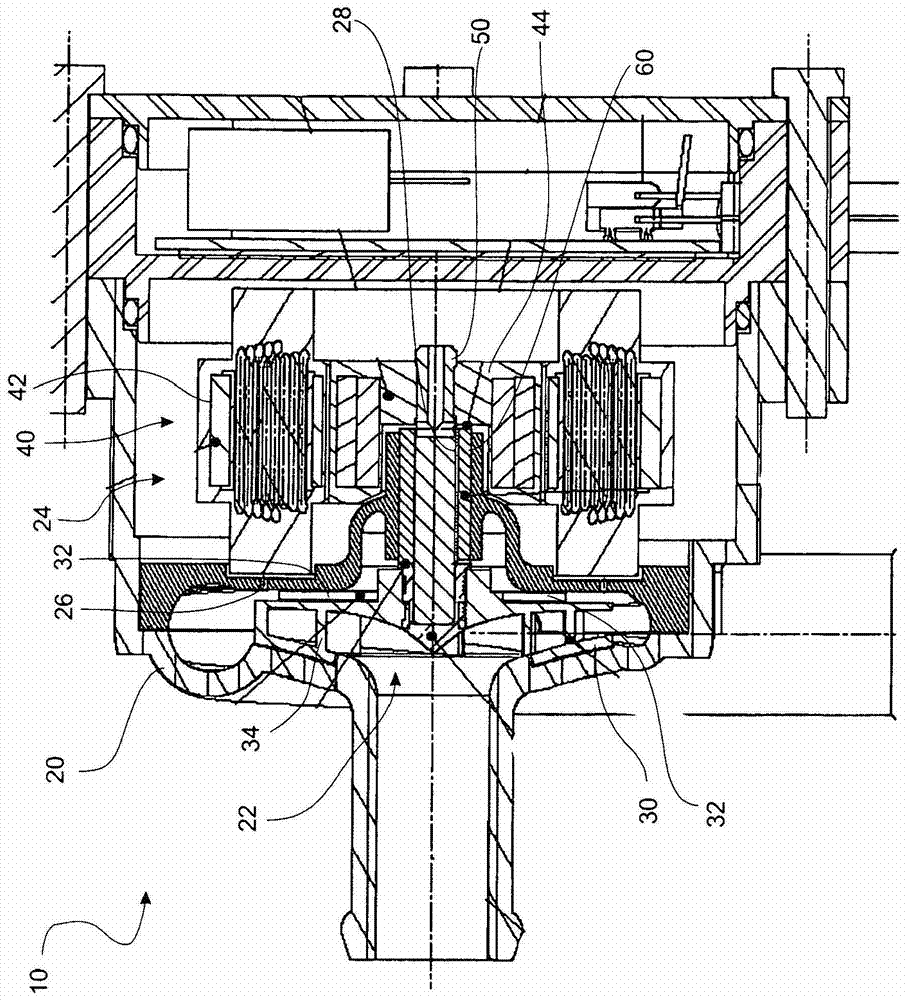

[0028] exist figure 1 An embodiment of a pump 10 according to the invention is schematically shown in . The pump 10 is provided with a housing 20 which has a pump chamber 22 and a motor chamber 24 formed in its interior. A motor 40 is formed in the motor chamber 24 , which is formed in the form of an electric motor in the present embodiment. The motor 40 is provided with a stator 42 inside which a rotor 44 rotates. The rotor 44 is connected rotationally torque-fittingly to the impeller 30 via a drive shaft 50 .

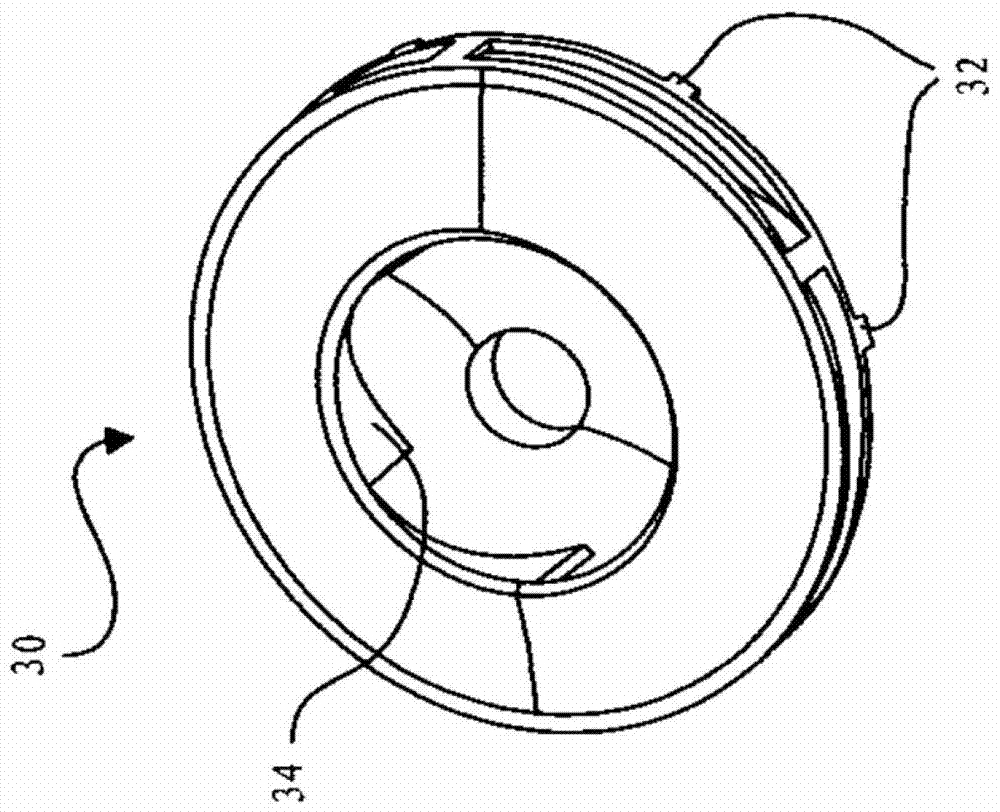

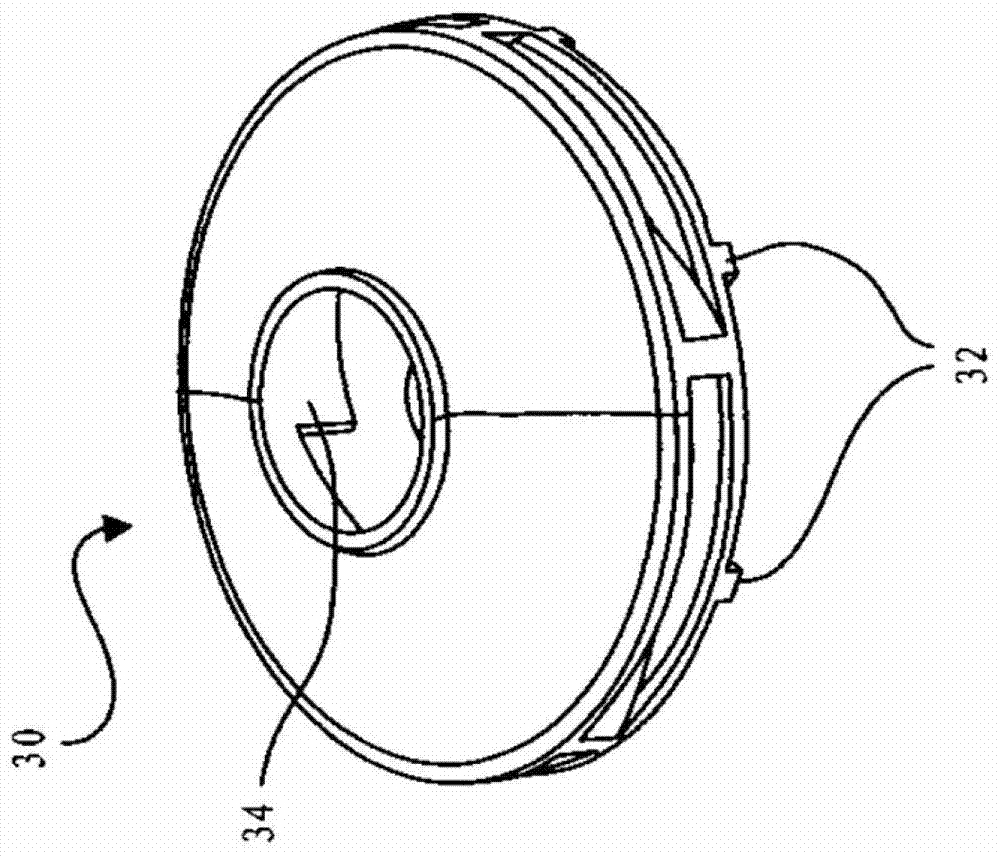

[0029] The impeller 30 is for example according to figure 2 , image 3 , Figure 4 or Figure 5 structure, which will be described in detail later. also, figure 1 The pump 10 according to the invention according to an embodiment of the present invention also has a suction connection which connects from the left to the suction side of the impeller 30 . Visible tangentially around the impeller 30 is a surrounding annular channel which serves for the output and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com