Double-closed-loop direct current motor control circuit

A technology for controlling circuits and DC motors, applied in the direction of DC motor rotation control, excitation or armature current control, etc., which can solve problems such as high energy consumption, low control accuracy, and high requirements for chip computing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

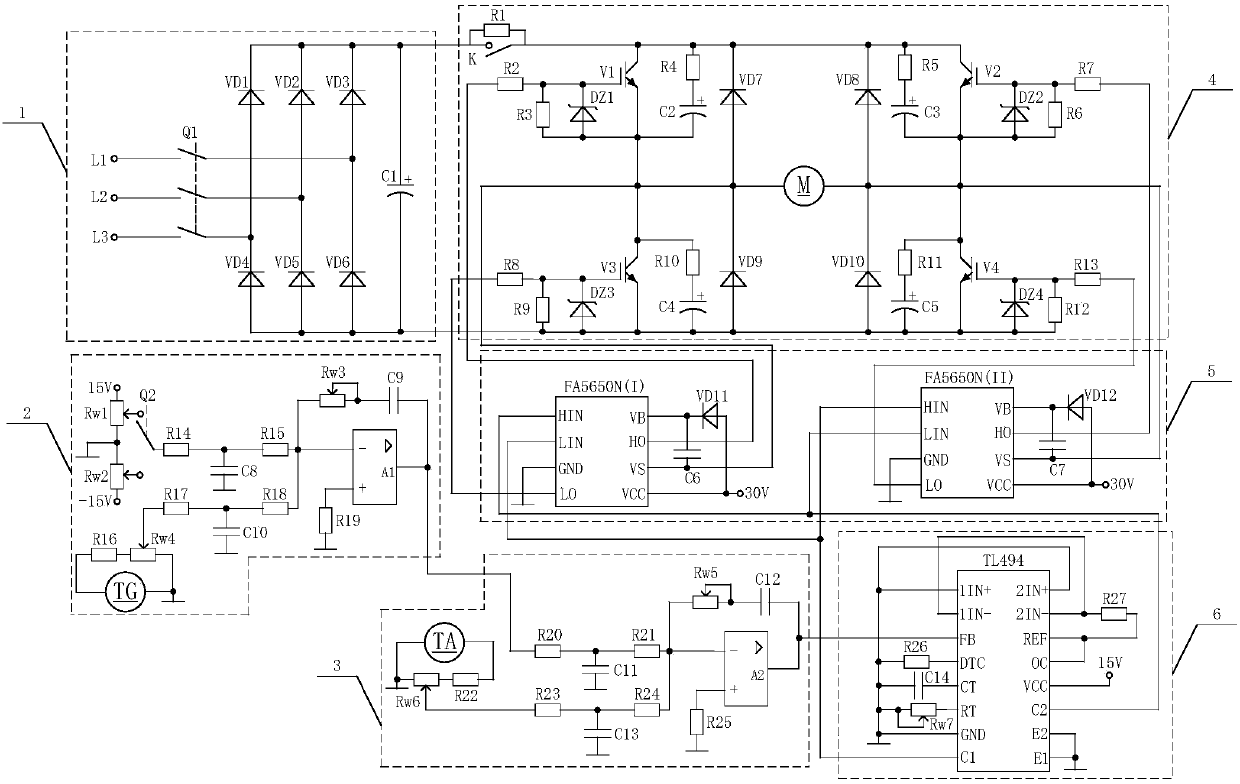

[0017] Embodiment 1: as figure 1 As shown, a double-closed-loop DC motor control circuit includes an uncontrollable rectification circuit 1, a speed setting and proportional integral circuit 2, a current loop proportional integral circuit 3, a motor H-bridge control circuit 4, and a high-power thyristor drive circuit 5 , PWM generating circuit 6; the speed setting and proportional integral circuit 2, current loop proportional integral circuit 3, PWM generating circuit 6, high-power thyristor drive circuit 5, motor H-bridge control circuit 4 are connected in sequence, uncontrollable rectification The circuit 1 is connected with the motor H bridge control circuit 4;

[0018] The uncontrollable rectification circuit 1 includes connection terminals L1, L2, L3, single-pole three-throw switch Q, diodes VD1, VD2, VD3, VD4, VD5, VD6, and capacitor C1; The throw switch is respectively connected to the anodes of diodes VD3, VD2, VD1, meanwhile, the anodes of diodes VD3, VD2, VD1 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com