Reflow oven cooling module with flat plate type coil pipe

A technology of reflow soldering furnace and cooling mold, applied in welding equipment, auxiliary devices, metal processing equipment, etc., can solve the problems of large volume, high cost, occupying equipment space, etc., and achieves large contact area, high wind speed, and convenient maintenance and cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

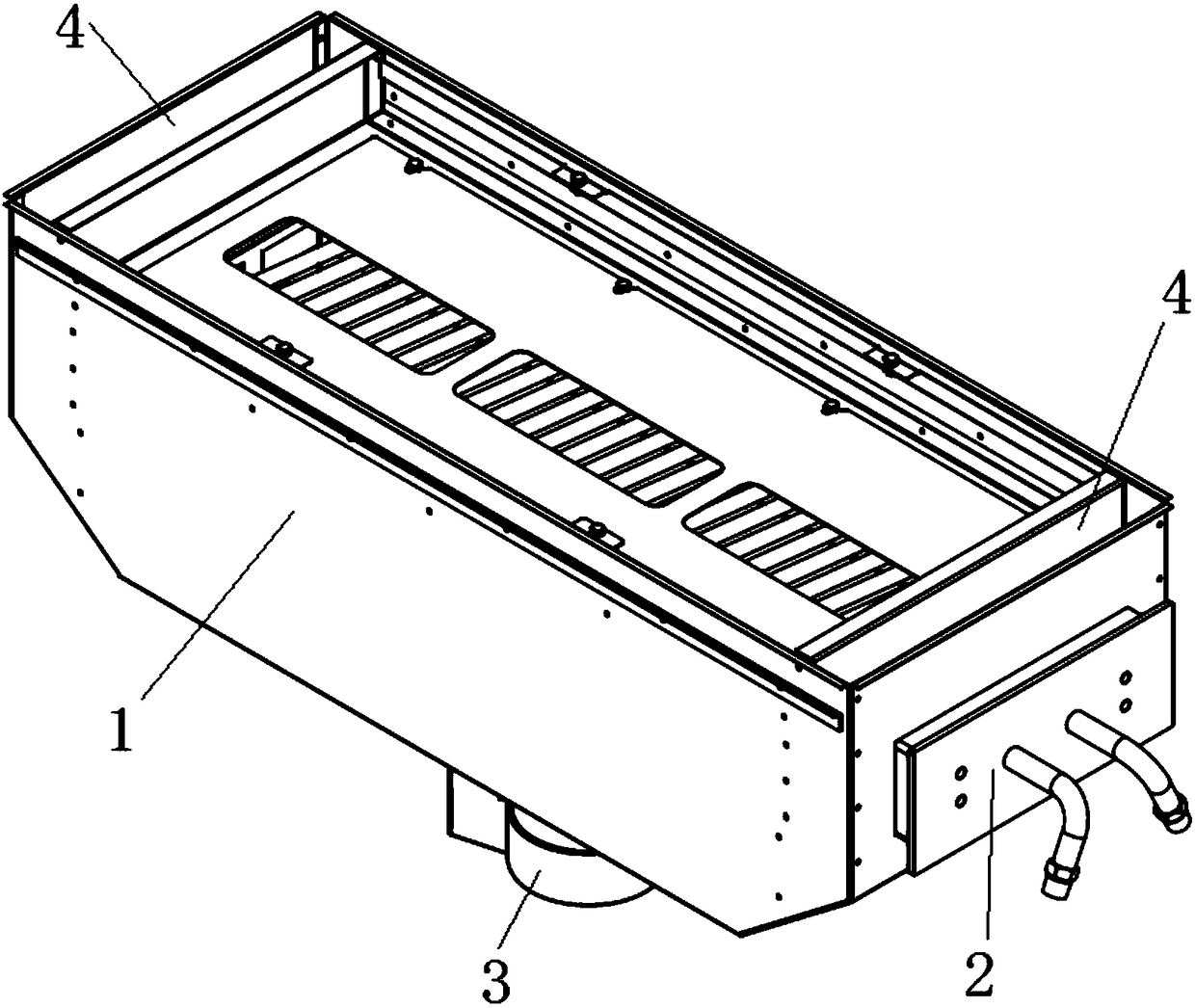

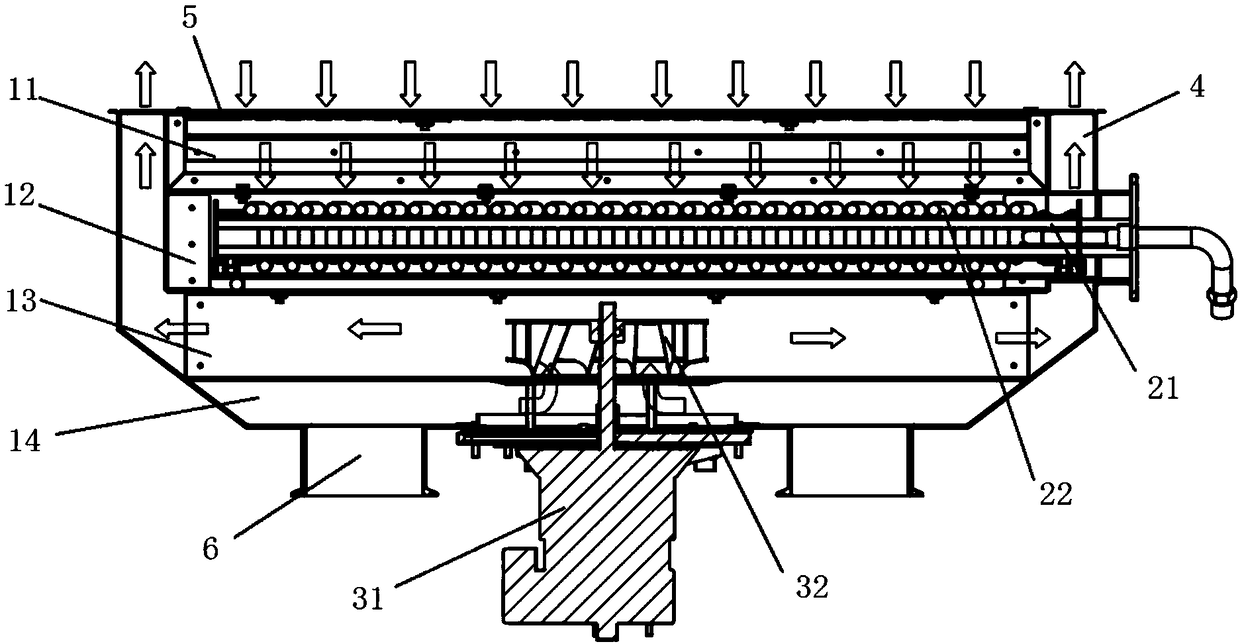

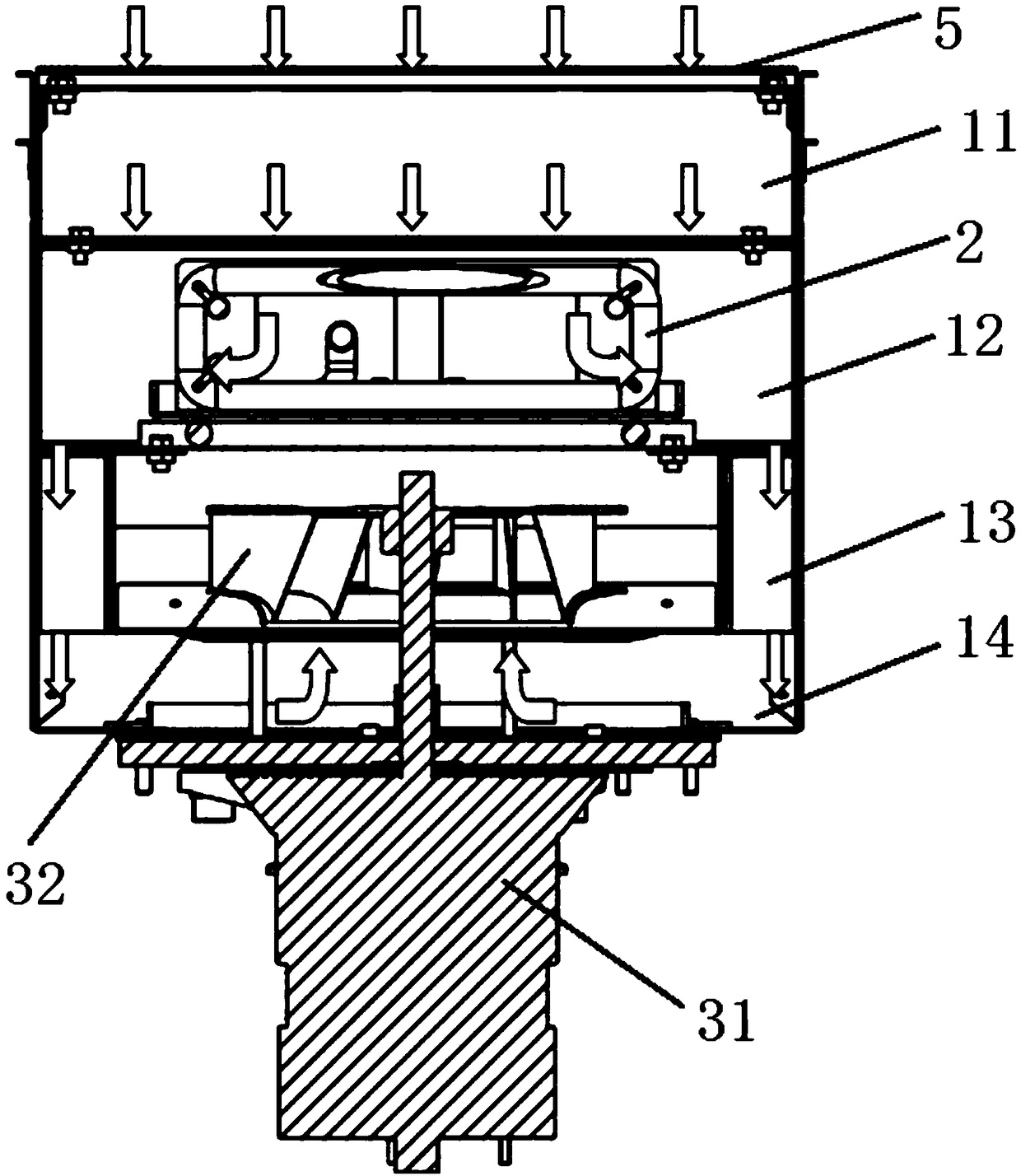

[0028] Such as Figure 1 ~ Figure 3 As shown, a reflow oven cooling module with a flat coil is installed at the outlet end of the bottom of the reflow oven. The cooling module includes a shell 1, a cooling coil 2 and a blowing unit 3. The shell 1 has three layers. Hollow structure, from top to bottom are the air inlet layer 11, the cooling layer 12 and the air outlet layer 13 respectively, between the air inlet layer 11 and the cooling layer 12 and between the cooling layer 12 and the air outlet layer 13 through the Partitions are used to isolate the air inlet layer 11. An air inlet hole plate 5 is arranged above the air inlet layer 11. A vertically arranged air outlet cavity 4 is arranged on both sides of the housing 1. The air outlet cavity 4 is connected to the air outlet layer 13. The bottom is sealed and the top is open. The top opening is connected to the top module on the top of the reflow oven. The top module is used to blow the cooled air to the PCB board located in t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap