Water ring particle cutting machine

A granulator and water ring technology, applied in the field of waste plastic granulation, can solve the problems of inconsistent water pressure, easy splashing, temperature drop on the die surface, etc., and achieve the effects of preventing mechanical damage, saving water resources, and facilitating drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

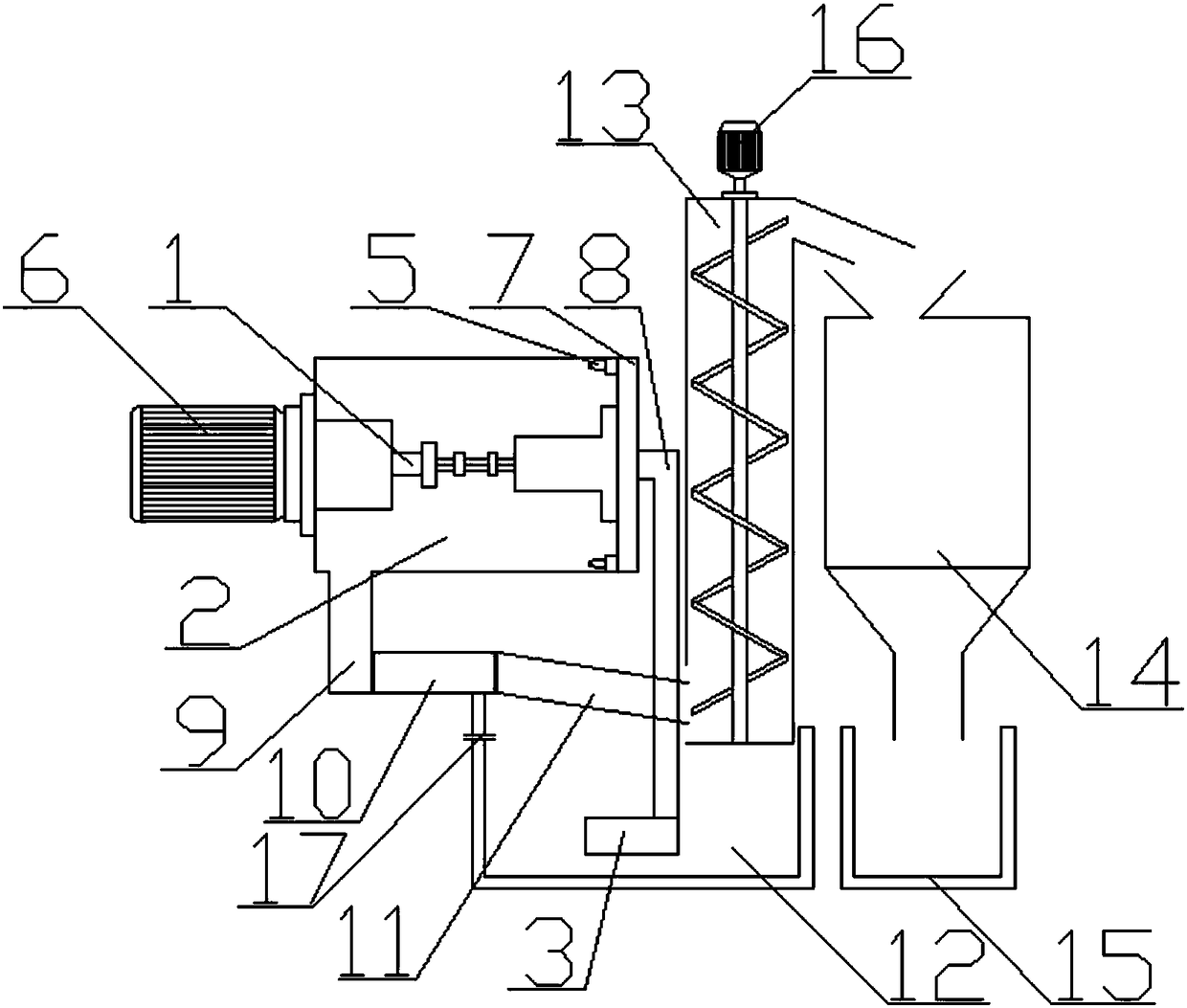

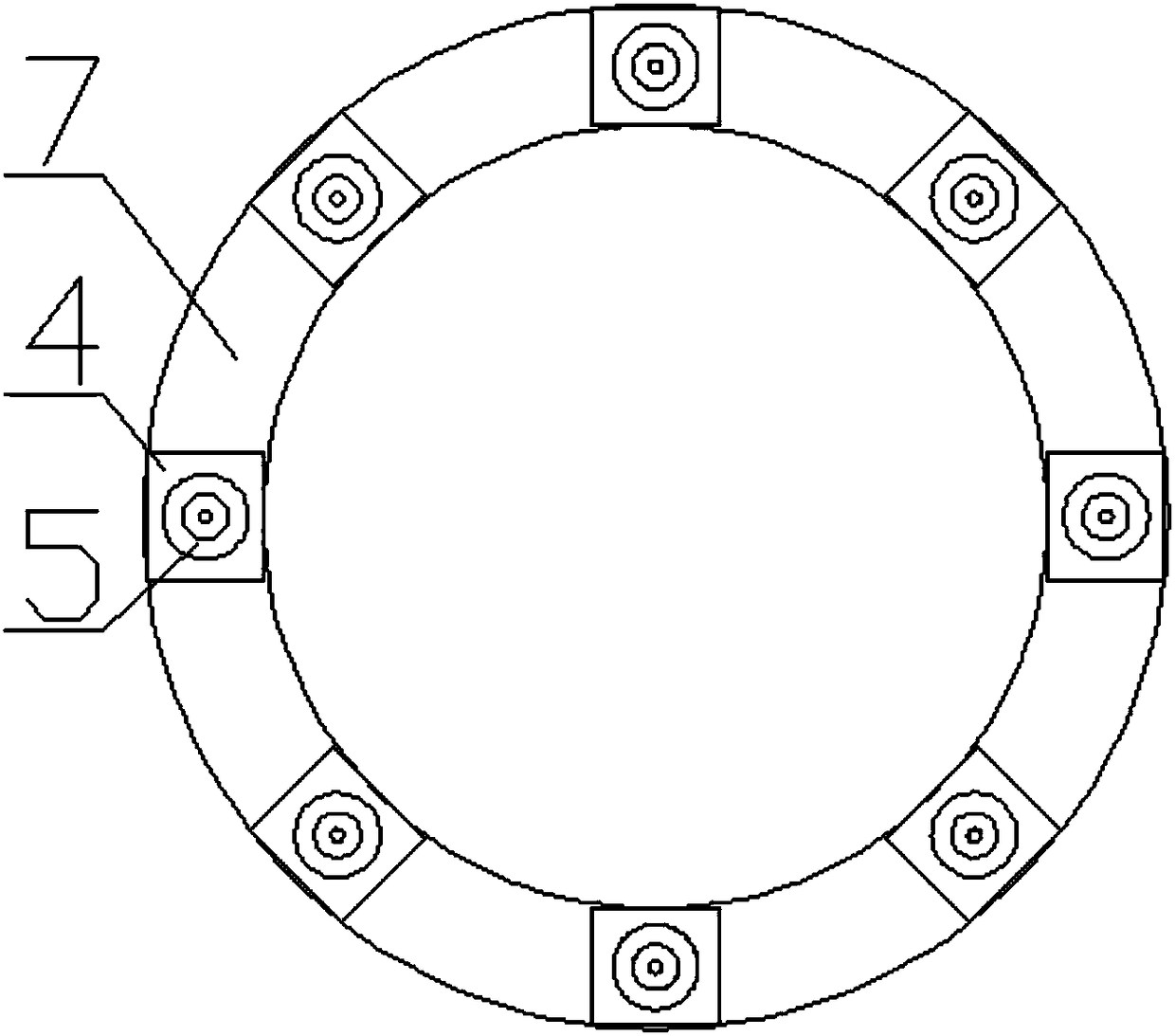

[0023] according to figure 1 and figure 2 A kind of water ring granulator shown, comprises granulator 1, water ring shell 2, water pump 3, plenum chamber 4 and nozzle 5, and described water ring shell 2 is horizontal cylindrical, and described granulator 1 is located inside the water ring shell 2, the granulation device 1 is connected to the center of both sides of the water ring shell 2, a motor 6 is provided on the left side of the water ring shell 2, and the motor 6 is connected to the granulation device 1, so The right side of the water ring shell 2 is provided with a communication chamber 7, the communication chamber 7 is in the shape of a ring, the right side of the communication chamber 7 is connected to the water pipe 8, the water pipe 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com