Overflow-preventing water tank

A technology of anti-overflow and water tank, which is applied in the direction of water supply devices, water supply main pipelines, water supply pipeline systems, etc., can solve the problems of short service life of sensors, inability to collect water, low control precision, etc., and achieve long service life, high use and promotion Value, the effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

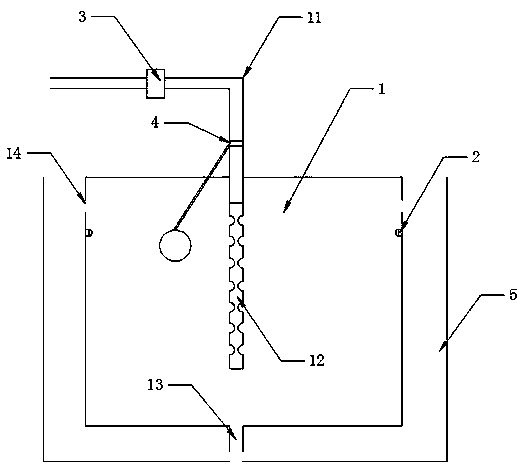

[0023] As shown in the figure, the present invention discloses an anti-overflow water tank with stable water inflow, high control precision, long service life of sensors and the ability to collect overflowing water.

[0024] Specifically, an anti-overflow water tank includes a water tank 1 and a water inlet pipe 11 fixedly arranged on the side wall of the water tank 1 for supplying water to the water tank 1, and is characterized in that it also includes a plurality of liquid A level sensor 2, a plurality of liquid level sensors 2 are fixedly arranged on the inner side wall of the water tank 1, a valve assembly is fixedly arranged on the water inlet pipe 11, and a buffer pipe 12 is also arranged in the water tank 1, The buffer pipe 12 is fixedly connected to the end of the water inlet pipe 11; a plurality of the liquid level sensors 2 are all arranged in the same plane, and the plane where the plurality of liquid level sensors 2 are located is the same as the liquid in the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com