Straw harvesting, crushing and kneading forced feeding round straw bundle baler

A technology of forced feeding and baler, which is applied to loaders, agricultural machinery and implements, cutting equipment, etc., and can solve the problem of not being able to complete straw harvesting, crushing and baling at the same time, and the inability to harvest straw and baler at the same time. Low efficiency and other problems, to achieve the effect of reducing processing costs, avoiding blockage, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

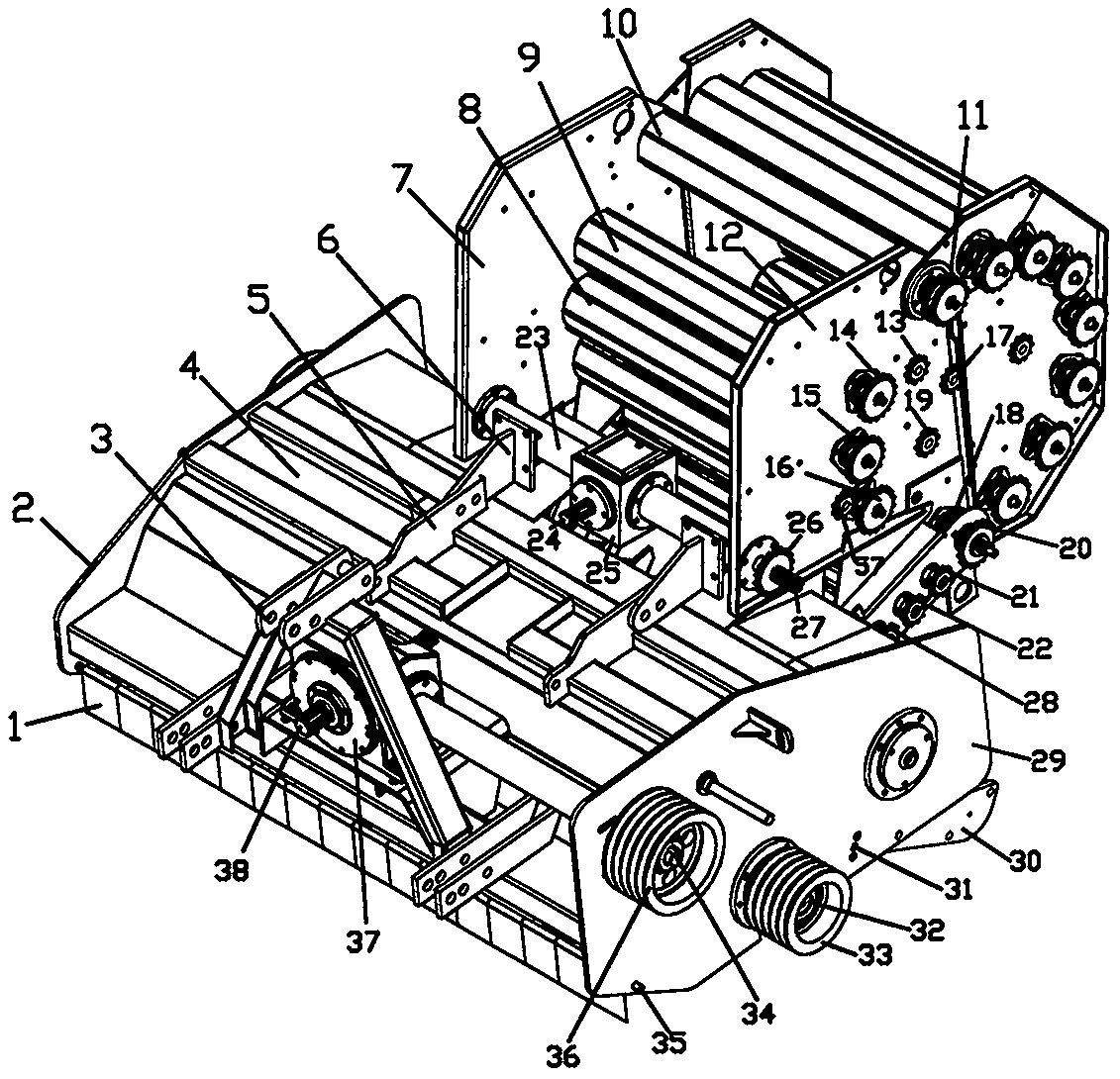

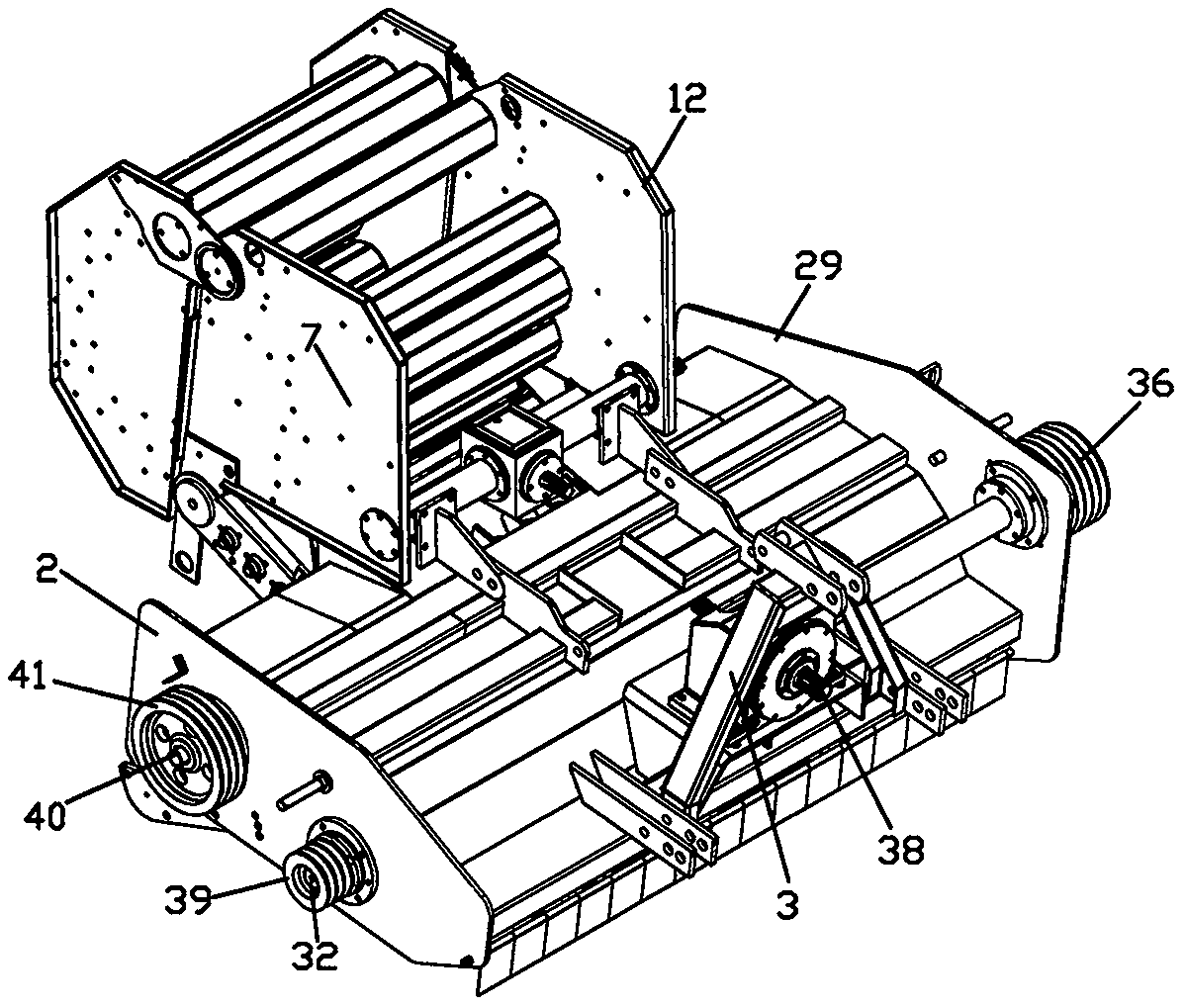

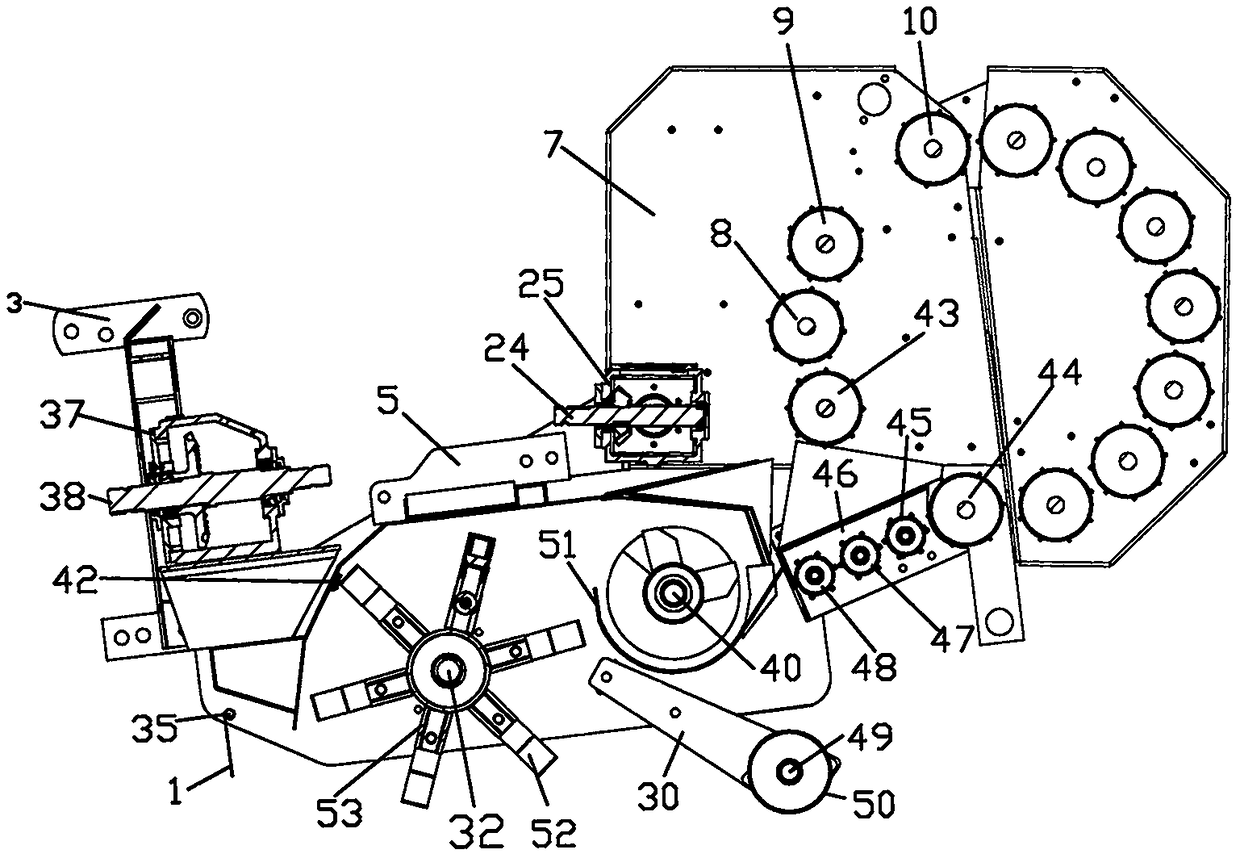

[0025] Such as Figure 1-Figure 8 As shown, the wide straw harvesting, crushing, kneading, and force-feeding round bale baler includes a picker 58, the first side plate 7 and the second side plate 12 of the front compression chamber, the first side plate 7, and the second side plate 12 are rotatably connected with the first roller 10 to the fifth roller 44, and the ends of the first roller 10 to the fifth roller 44 are fixedly connected with the first sprocket 11 to the fifth sprocket 18, and the first side The front lower corner of the plate 7 and the second side plate 12 is fixedly connected to the baling reduction box 25 through the shaft tube 23, and the baling power input shaft 24 of the baling reduction box 25 passes through the baling power output shaft 27 and the baling power output sprocket 26. Transmission connection, the pressing power output sprocket 26 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com