Paper diaper composite core and processing method thereof

A composite core and diaper technology, applied in the fields of medical science, absorbent pads, bandages, etc., can solve the problems of easy agglomeration, easy to have dust, affecting the working environment, etc., and achieve the effect of accelerating absorption, convenient processing, and improving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

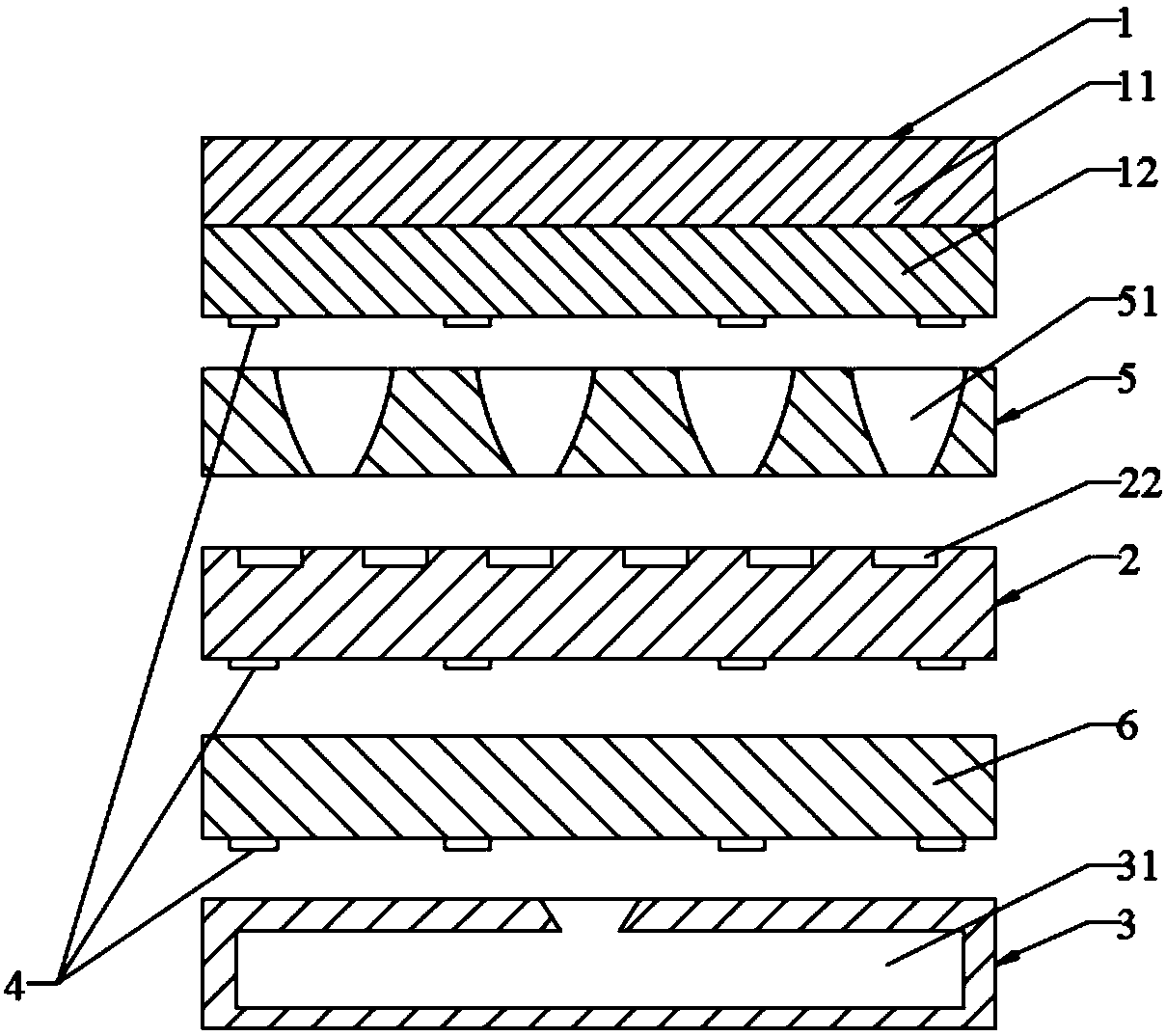

[0049] Please refer to Figure 1 to Figure 3 Shown, embodiment one of the present invention is:

[0050] A composite core body for diapers, the composite core body includes a surface layer 1, a wood pulp paper layer 2 and a waterproof layer 3 arranged sequentially from top to bottom;

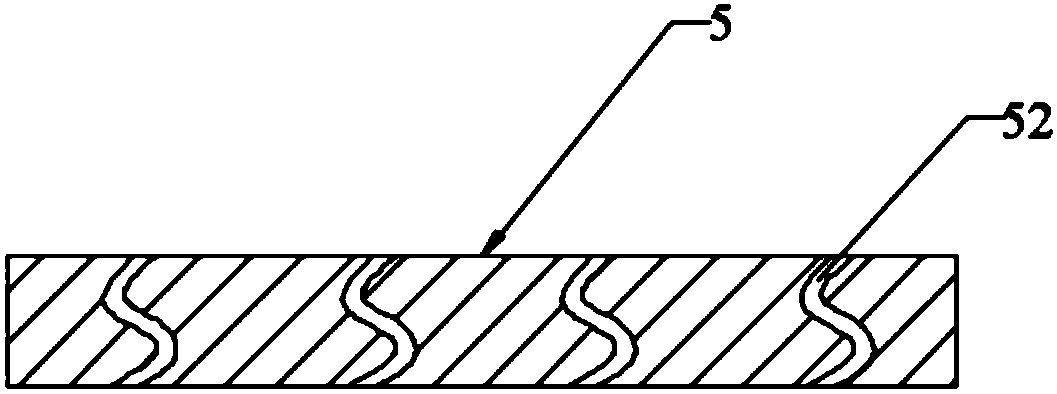

[0051] The surface layer 1 includes a soft layer 11 and a hydrophilic non-woven layer 12, the soft layer 11 is arranged on the upper surface of the hydrophilic non-woven layer 12, and the soft layer 11 is provided with aromatic substances, The upper surface and the lower surface of the hydrophilic non-woven fabric layer 12 are provided with a plurality of strip-shaped and spaced glue-coating points 4, and the soft layer 11 passes through the glue-coating spots 4 and the hydrophilic non-woven fabric layer 12. The upper surface of the wood pulp paper layer 2 is connected to the lower surface of the hydrophilic non-woven fabric layer 12 through the glue point 4;

[0052] The wood pulp paper layer...

Embodiment 2

[0059] Please refer to Figure 1 to Figure 3 Shown, another embodiment two of the present invention is:

[0060] The present invention also provides a processing method for the composite core of diapers, which is applied to the composite core of diapers described in Example 1. The processing method includes the following steps:

[0061] Step 1, coating the lower surface of the surface layer 1 with a plurality of strip-shaped glue dots 4 arranged at intervals;

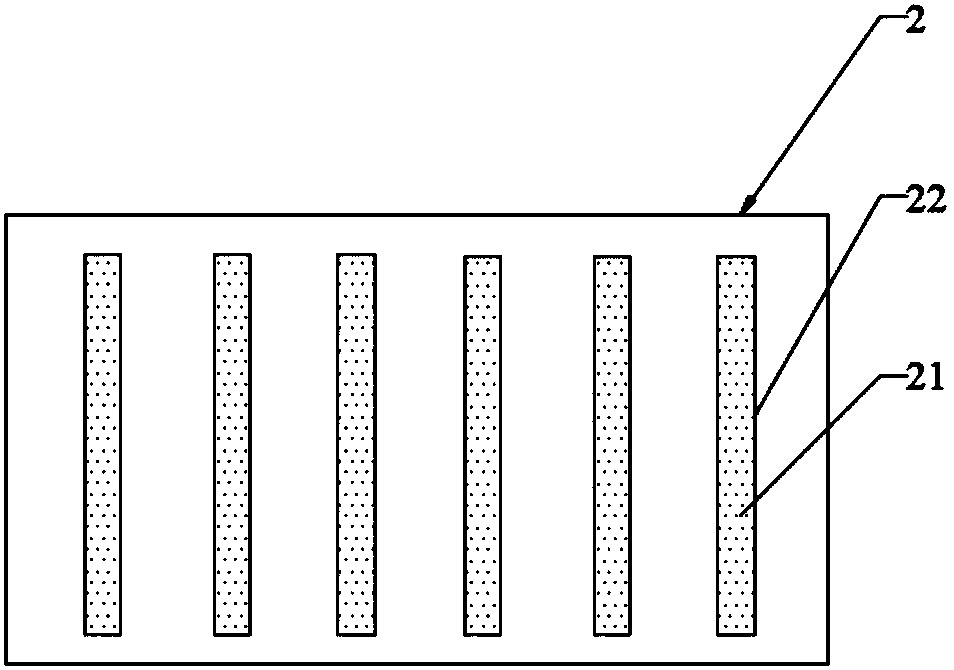

[0062] Step 2, process a plurality of parallel ditches 22 on the upper half of the wood pulp paper layer 2, transport the polymer water-absorbing particles 21 to the ditches 22 of the wood pulp paper layer 2 through the feeding syringe, and absorb the polymer water The particles 21 are arranged at intervals in the ditch 22;

[0063] Step 3, laying the surface layer 1 described in step 1 on the wood pulp paper layer 2 sprinkled with polymer water-absorbing particles 21 described in step 2, and the surface layer 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com