A continuous translation rolling mill and rolling method thereof

A translational, continuous technology, applied in mechanical equipment, metal rolling, shafts and bearings, etc., can solve problems such as inability to meet workpiece accuracy, rolling force fluctuations, etc., and achieve a favorable plastic deformation process and reduce deformation load , the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

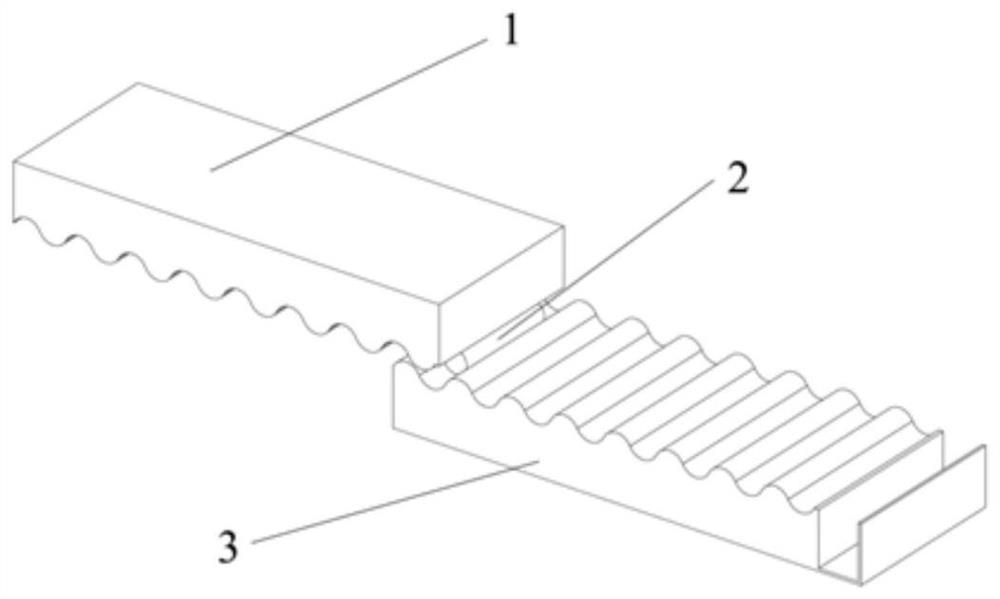

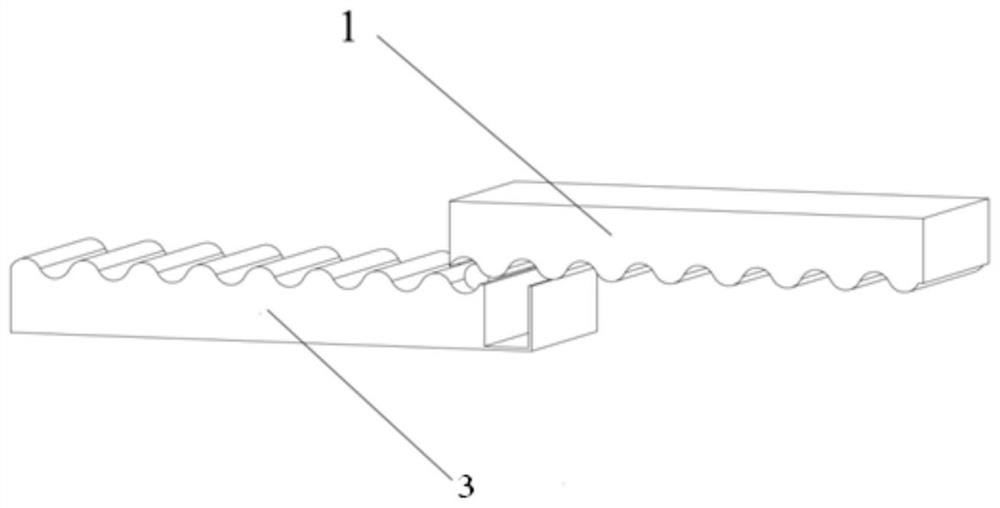

[0035] This embodiment is a processing device for making blanks of shaft forgings. This embodiment includes an upper roller 1 and a lower roller 3 whose shape is a sinusoidal translational wave roller; the upper roller 1 and the lower roller 3 have the same structure and are assembled in opposite directions, that is, the peak position of the upper roller 1 corresponds to the valley position of the lower roller 3 , to meet the meshing of the upper and lower rollers during translation. Adjust the axis distance to change the roller gap to adapt to different sizes of shaft processing. Through the transmission device, the workpiece can be continuously rolled.

[0036]The distance between the upper and lower roller contour curves and the bottom of the rollers is 120mm, the roller width is 320mm, and the roller length is 800mm. After the installation is completed, the lower roller 3 is fixed, the upper roller 1 is parallel to the lower roller 3, and the initial distance between the...

Embodiment 2

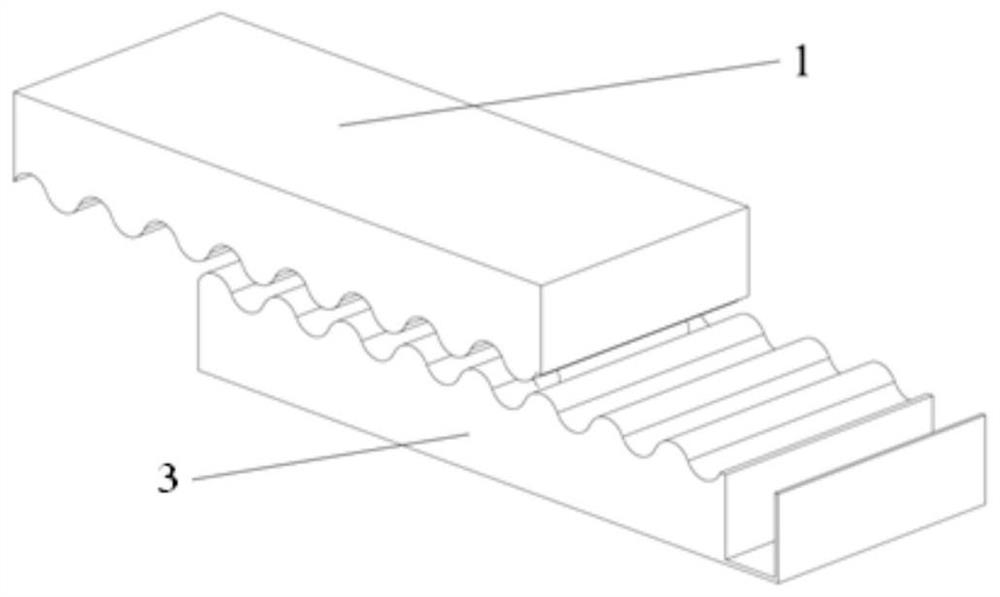

[0039] This embodiment is a processing device for making blanks of shaft forgings. This embodiment includes an upper roller 1 and a lower roller 3 whose shape is a sinusoidal translational wave roller; the upper roller 1 and the lower roller 3 have the same structure and are assembled in opposite directions, that is, the peak position of the upper roller 1 corresponds to the valley position of the lower roller 3 , to meet the meshing of the upper and lower rollers during translation. Adjust the axis distance to change the roller gap to adapt to different sizes of shaft processing. Through the transmission device, the workpiece can be continuously rolled.

[0040] The distance between the contour curve of the upper and lower rollers and the bottom of the roller is 80mm, the width of the roller is 350mm, and the length of the roller is 980mm. After the installation is completed, the lower roller 3 is fixed, the upper roller 1 is parallel to the lower roller 3, and the initial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com