Full-automatic replacement electrode head device for welding

An electrode head, fully automatic technology, applied in the direction of electrode characteristics, welding equipment, resistance welding equipment, etc., can solve the problems of excessive wear of the conical surface of the electrode connecting rod, instability of the upper and lower parallel end faces, and shortening the life of the electrode connecting rod, etc., to achieve Simple structure, easy maintenance and management, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

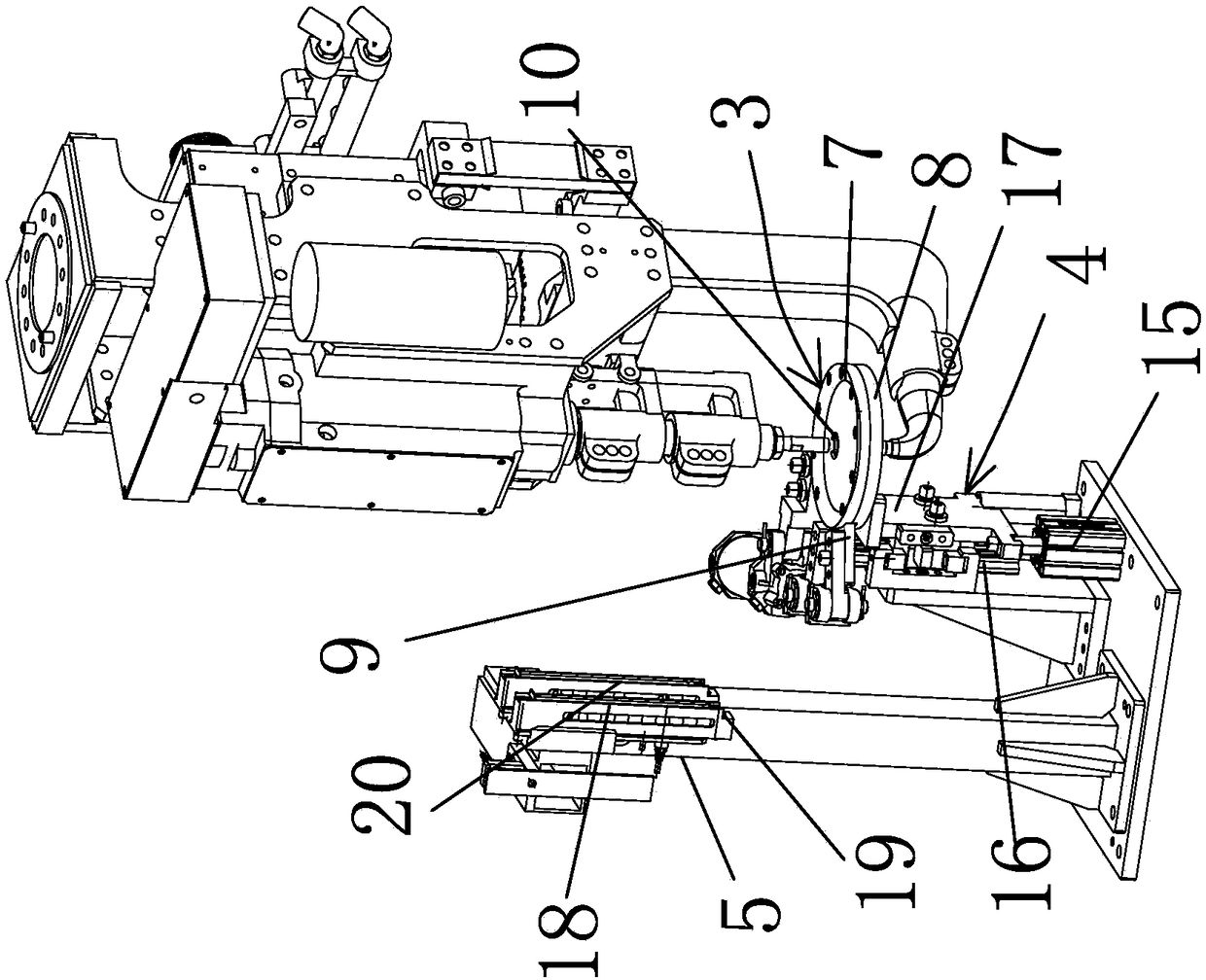

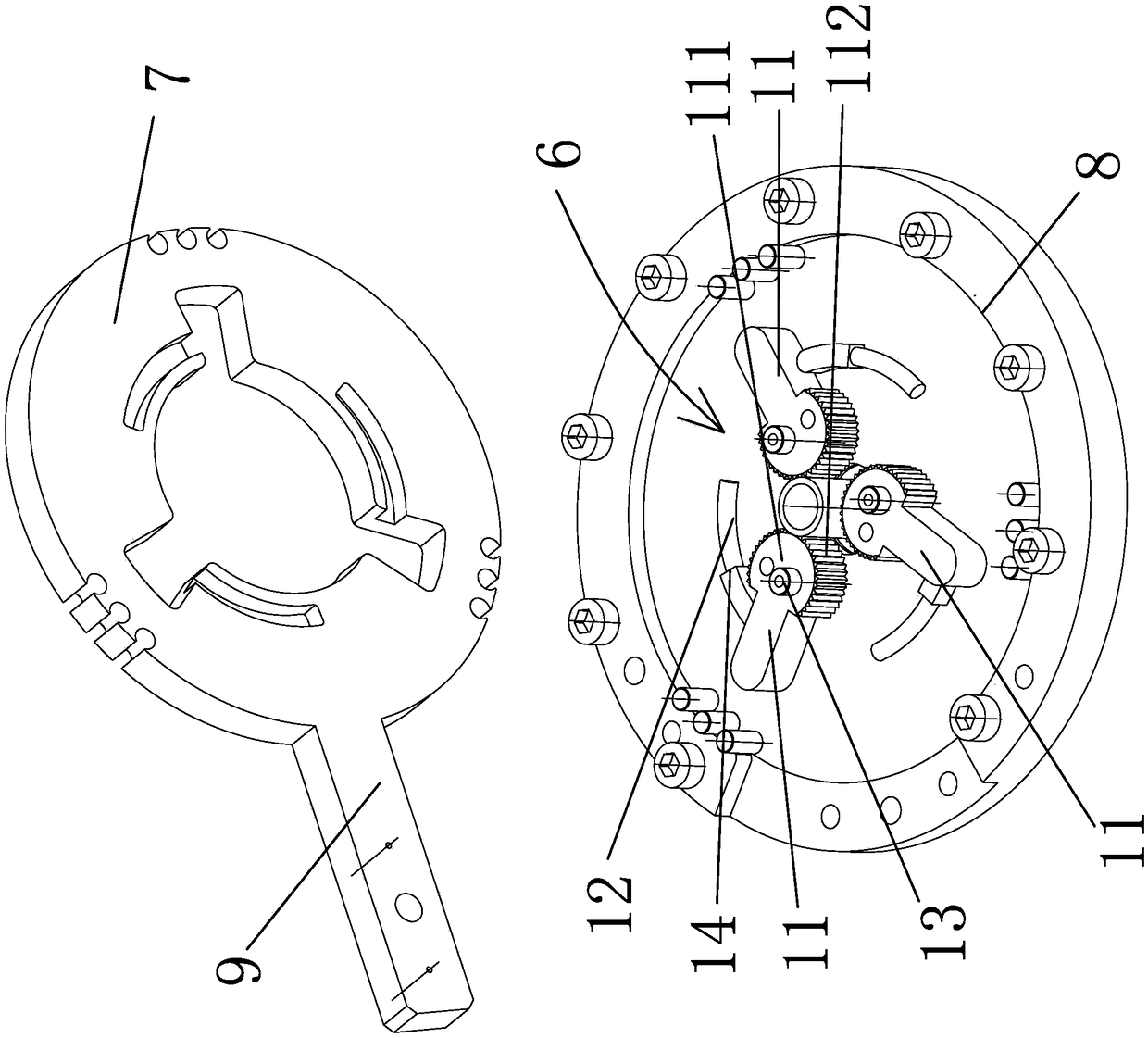

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

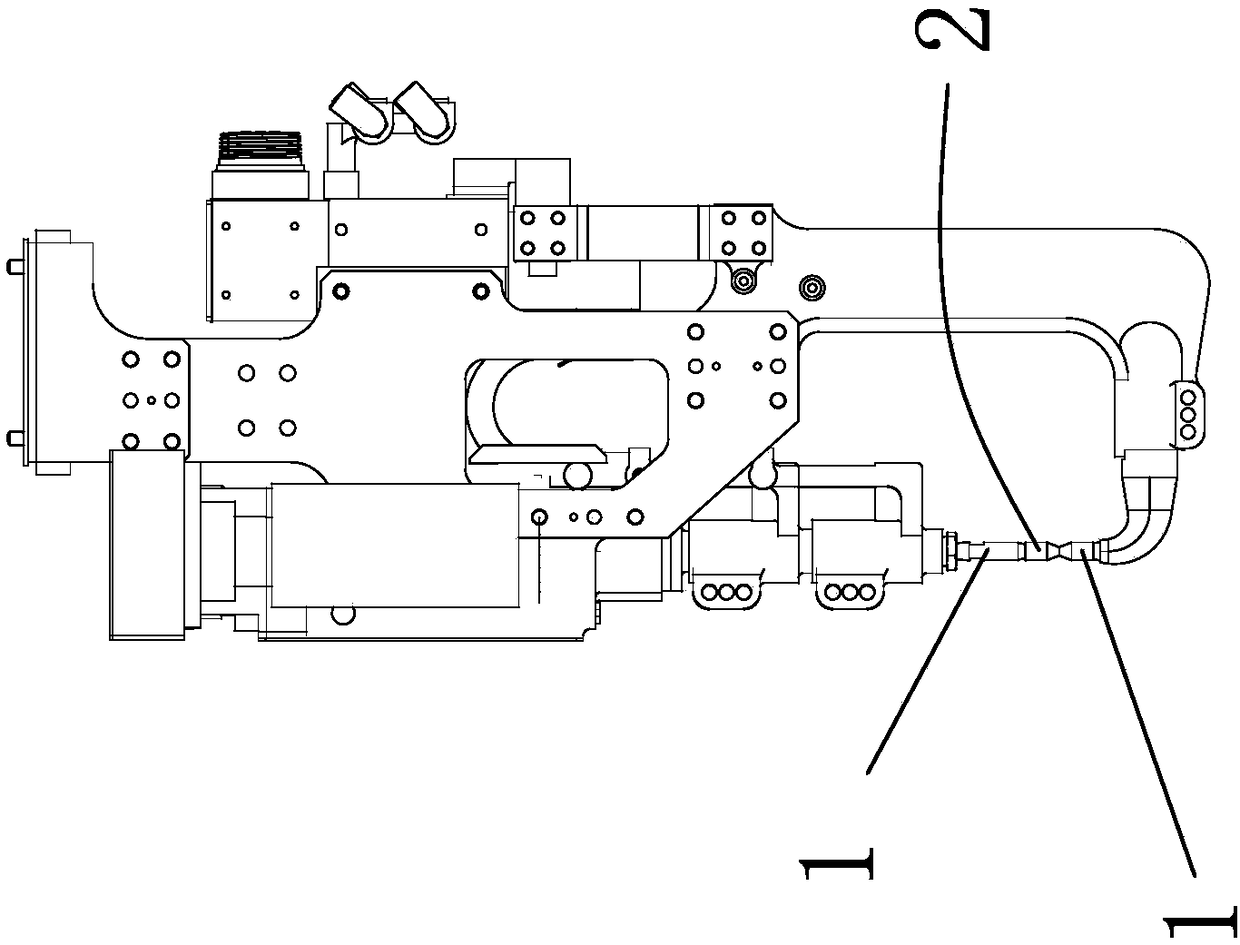

[0019] In the figure, the electrode connecting rod 1; the electrode head 2; the secondary rotating assembly 3; the separation assembly 4; the pick-and-place mechanism 5; Electrode head replacement slot 10; claw piece 11; claw part 111; claw main body 112; return spring 12; hinge joint 13; spring retaining groove 14; separation cylinder 15; Electrode head storage box 18; replace outlet tank 19; recycle storage box 20.

[0020] like figure 1 and figure 2 As shown in the figure, the automatic electrode tip replacement device for welding is used to automatically change the electrode tip 2 between the upper and lower electrode connecting rods 1 of the welding tongs, including the secondary rotating assembly 3, the separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com