Intelligent automatic induction heating device

An automatic induction and heating device technology, applied in auxiliary devices, metal processing equipment, auxiliary welding equipment, etc., can solve the problems of little research and reports on the automation integration of HHT technology, and achieve the effect of improving stability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

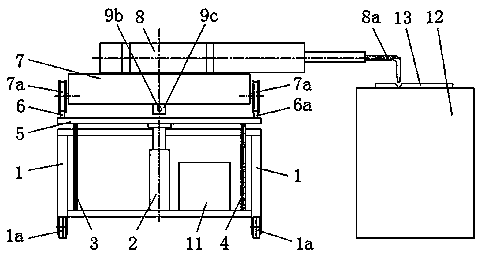

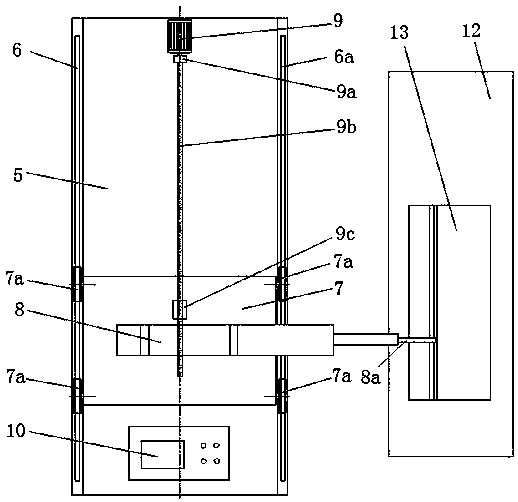

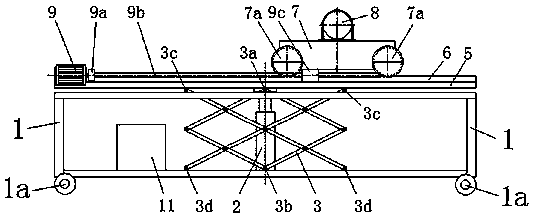

[0021] figure 1 , 2 , 3 shows a structural diagram of an intelligent automatic induction heating device. In the figure, this intelligent automatic induction heating device includes a vehicle frame 1, a transformer 8, an induction coil 8a, a control panel 10, a weldment 13, a cast iron platform 12, a lifting platform 5, a lifting mechanism, a workbench 7 and a translation drive mechanism. The lifting platform 5 is set on the top of the vehicle frame 1, and the lifting platform 5 and the vehicle frame 1 are connected by a lifting mechanism including a cylinder 2, a first parallel rod mechanism 3 and a second parallel rod mechanism 4, and the first parallel rod mechanism The mechanism 3 and the second parallel rod mechanism 4 are telescopic structures composed of a plurality of flat steel plates of the same length hingedly connected to each other. The workbench 7 moves on the first guide rail 6 and the second guide rail 6a through four guide wheels 7a, the first guide rail 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com