XPS foam board transverse cutting machine

A technology of cross-cutting machine and foam board, which is applied in metal processing and other directions, can solve the problems that cutting cannot keep up with the production rhythm and limit production efficiency, and achieve the effect of improving cutting efficiency, high cutting efficiency and fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

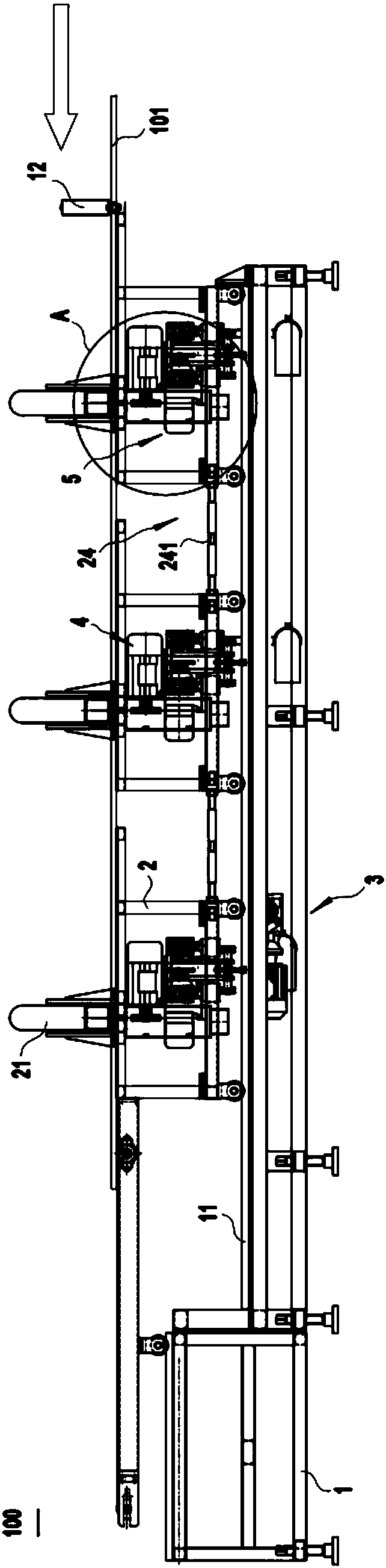

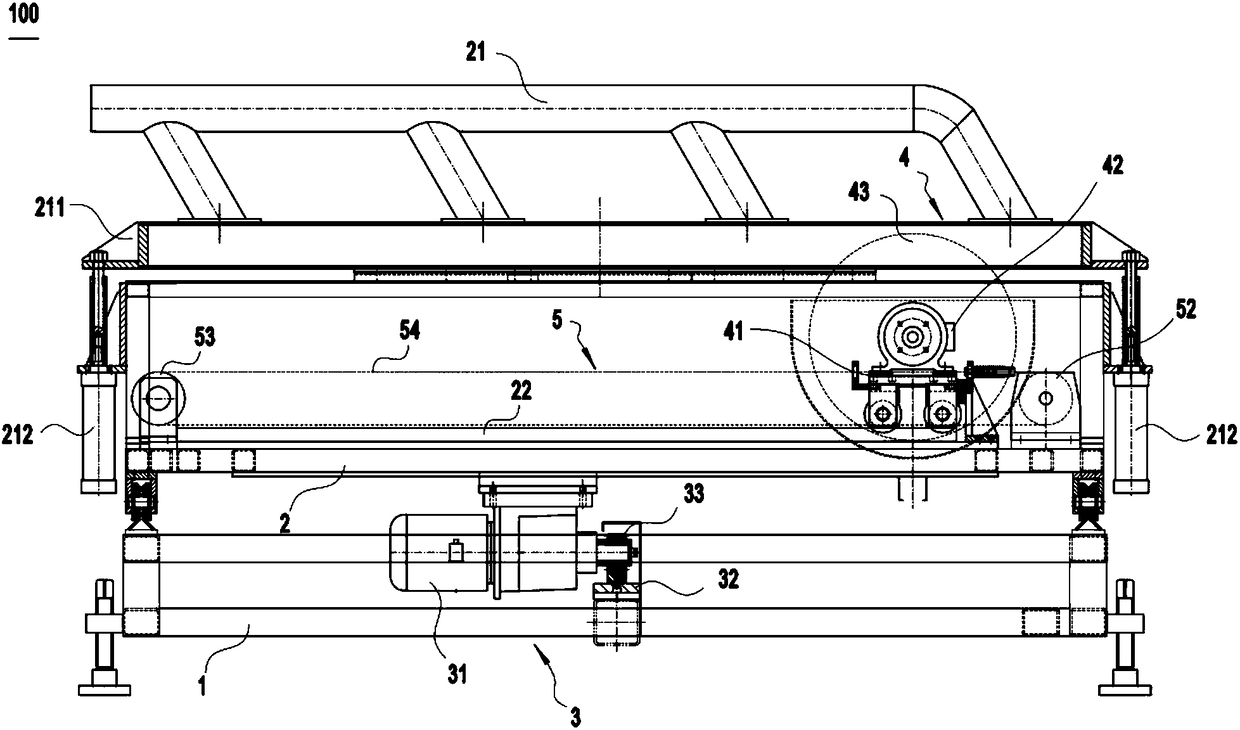

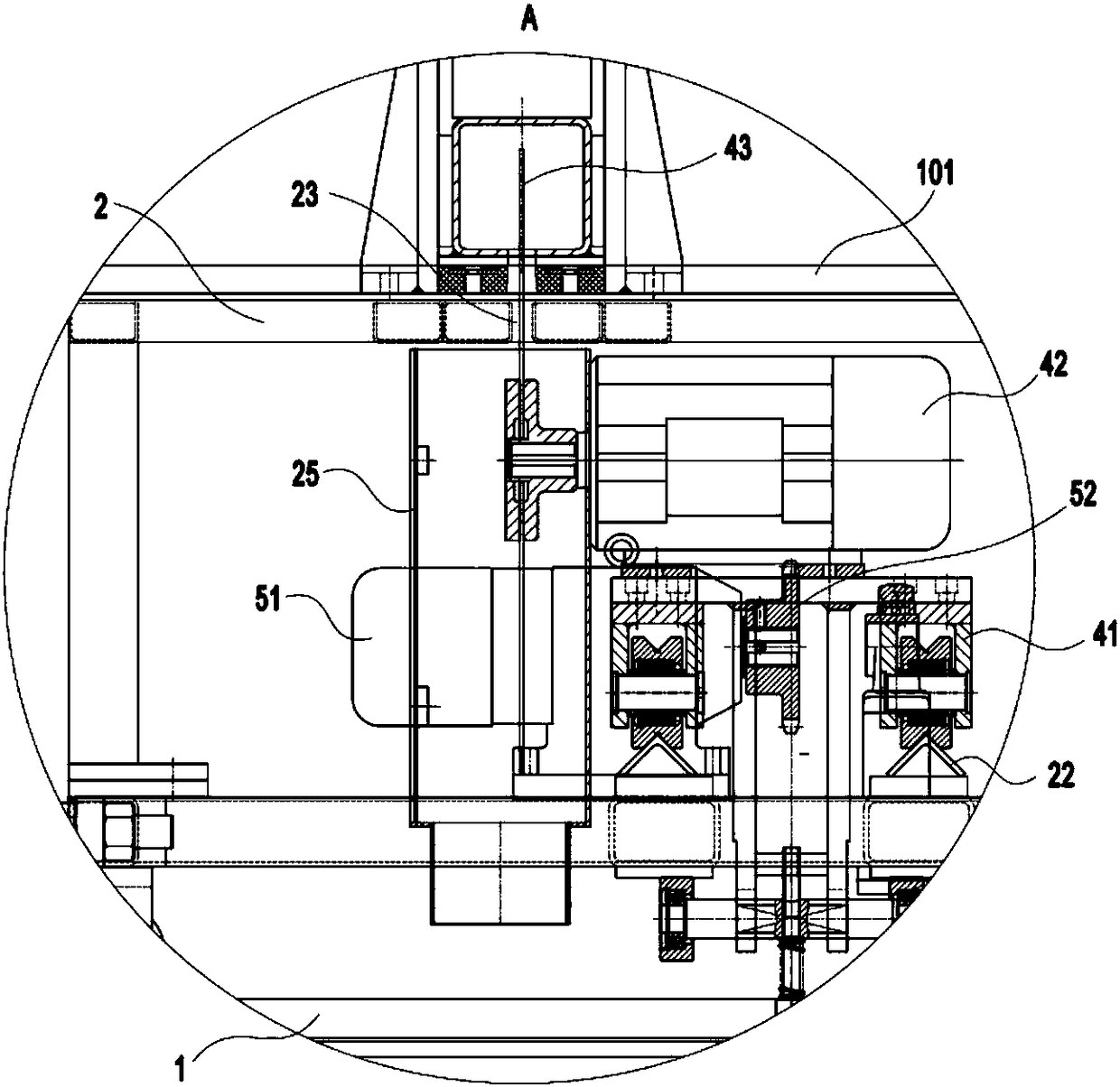

[0026] In order to describe the technical content, structural features, achieved goals and effects of the invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings. Among them, the up, down, left, right, front, back and attached in this embodiment figure 1 The up, down, left, right, front and back of the XPS foam board cross-cutting machine shown in figure 1 The direction along the front and rear extension of the XPS foam board cross cutting machine shown in , "longitudinal" is attached figure 1 The direction extending left and right along the XPS foam board cross cutting machine shown in .

[0027] According to attached figure 1 As shown, the XPS foam board cross-cutting machine 100 includes a frame 1, on which a longitudinal guide rail 11 extending along the left and right is fixedly arranged, and three cutting platforms 2 are slidably connected to the longitudinal guide rail 11, each cutting platform 2 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com