Coiling block paper die-cutting machine with waste removing function

A die-cutting machine and paper web technology, which is applied in metal processing and other directions, can solve the problems of not having the functions of automatic waste removal, finished product collection and waste edge collection, and achieve the effect of simple structure and good linkage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below by specific embodiment:

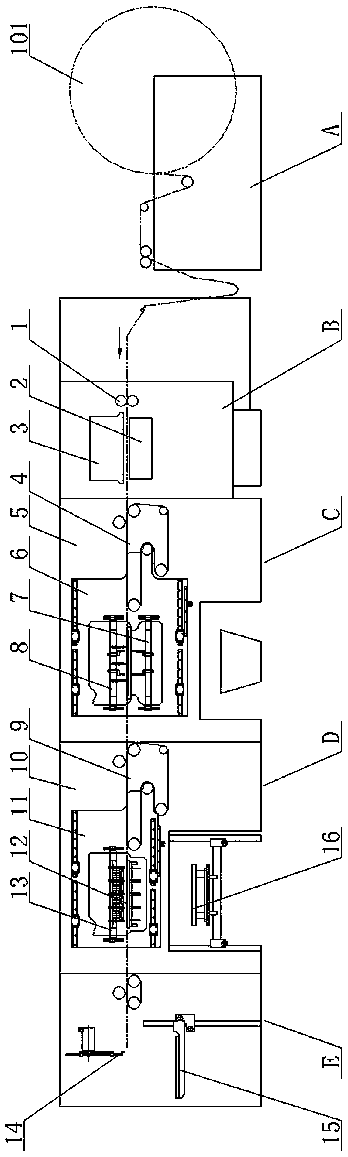

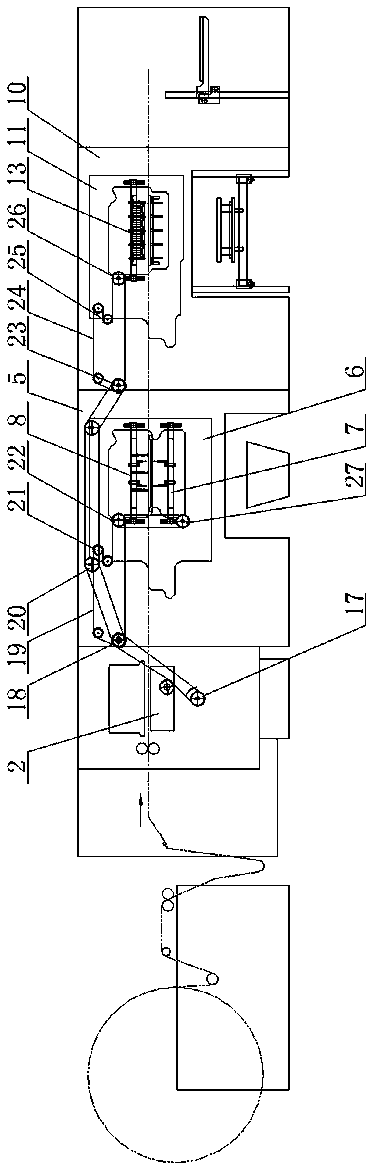

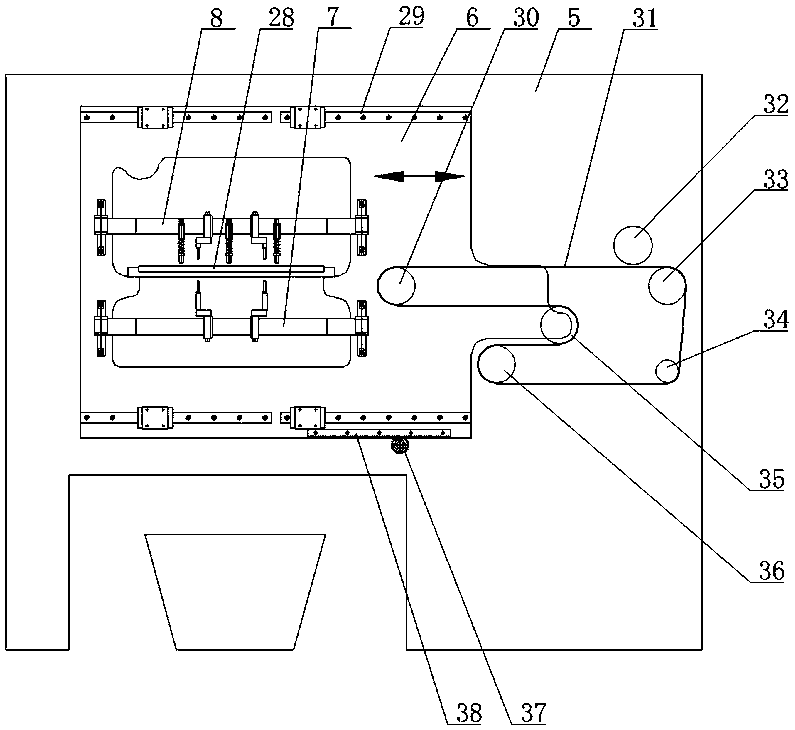

[0026]As shown in the figure, the web tape stripping die-cutting machine of the present invention consists of a web unwinding unit A, a die-cutting unit B, a waste stripping unit C, a finished product stripping unit D and a waste edge collection unit E arranged in sequence Composition, the roll paper unwinding unit A releases the roll paper 101, the die-cutting unit B die-cuts the roll paper 101, the waste cleaning unit C pokes out the small waste 102 in the middle of the die-cut product, and the finished product unit D Push the die-cut product out of the roll paper, and the waste edge collecting unit F collects the remaining waste edge. The die-cutting unit includes a fixed die-cutting upper die 3 and a die-cutting lower die 2 movable up and down, and the stripping unit includes a stripping frame 5, a stripping mold mounting plate 6, and a stripping upper and lower die, and a stripping top die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com