A kind of glass fiber reinforced plastic pipe production process

一种生产工艺、玻璃钢的技术,应用在管状物品、家里用具、其他家里用具等方向,能够解决操作过程繁复、产品强度和刚度差等问题,达到提高防腐蚀、提高强度、延长使用寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be described clearly and completely below with reference to the accompanying drawings in the embodiments of the present invention.

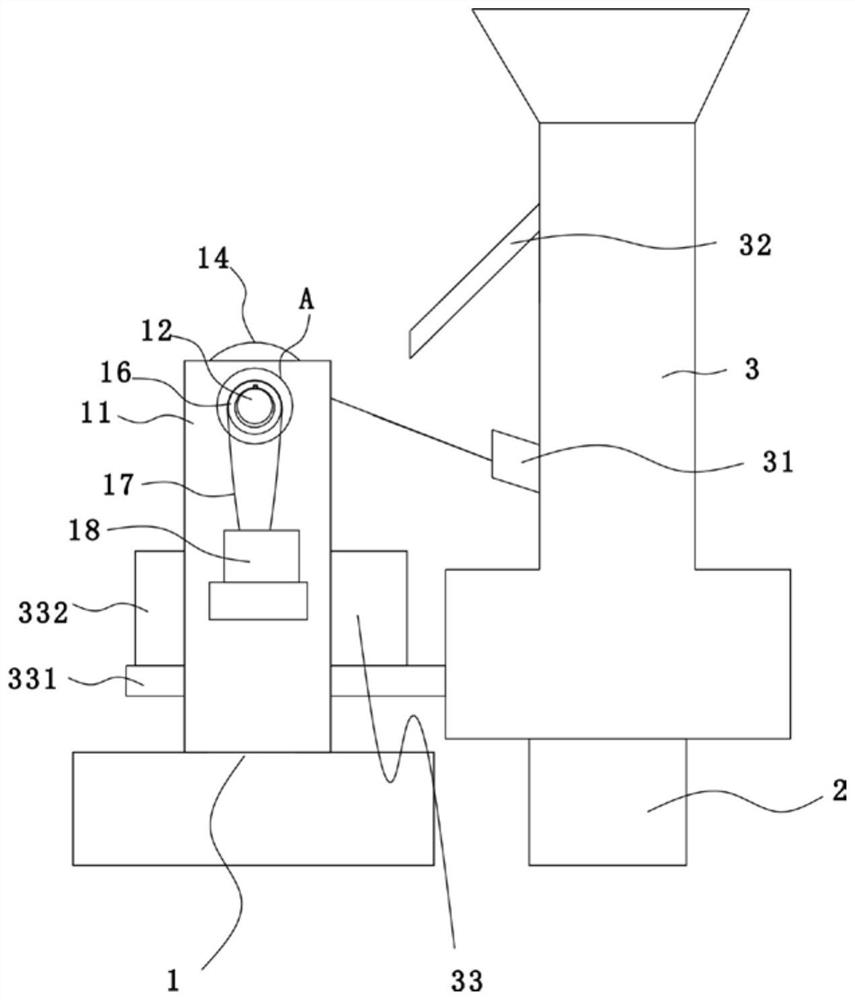

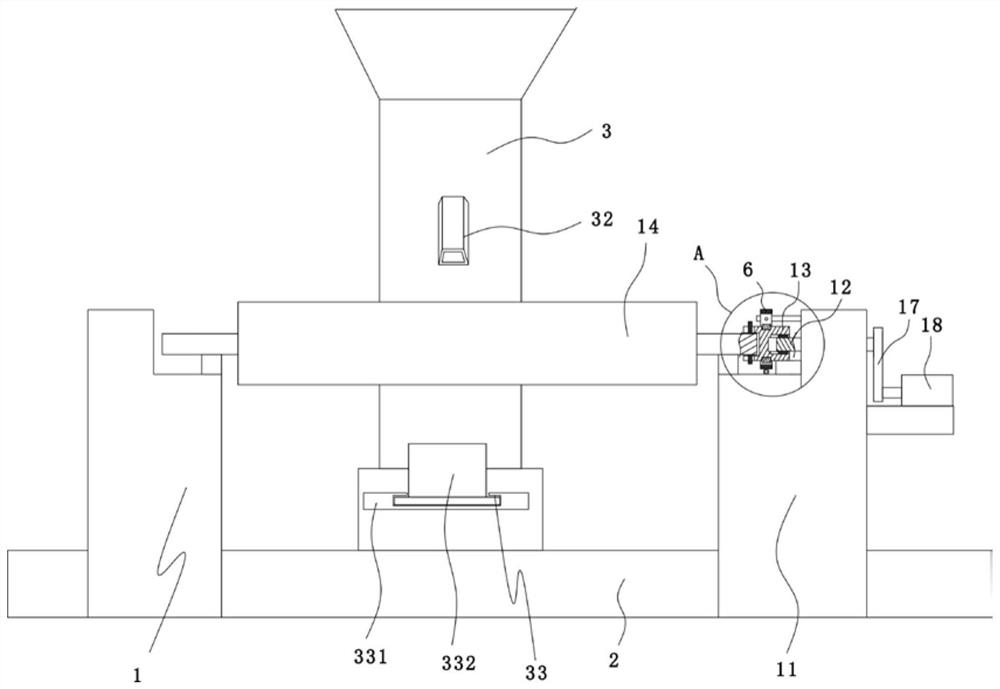

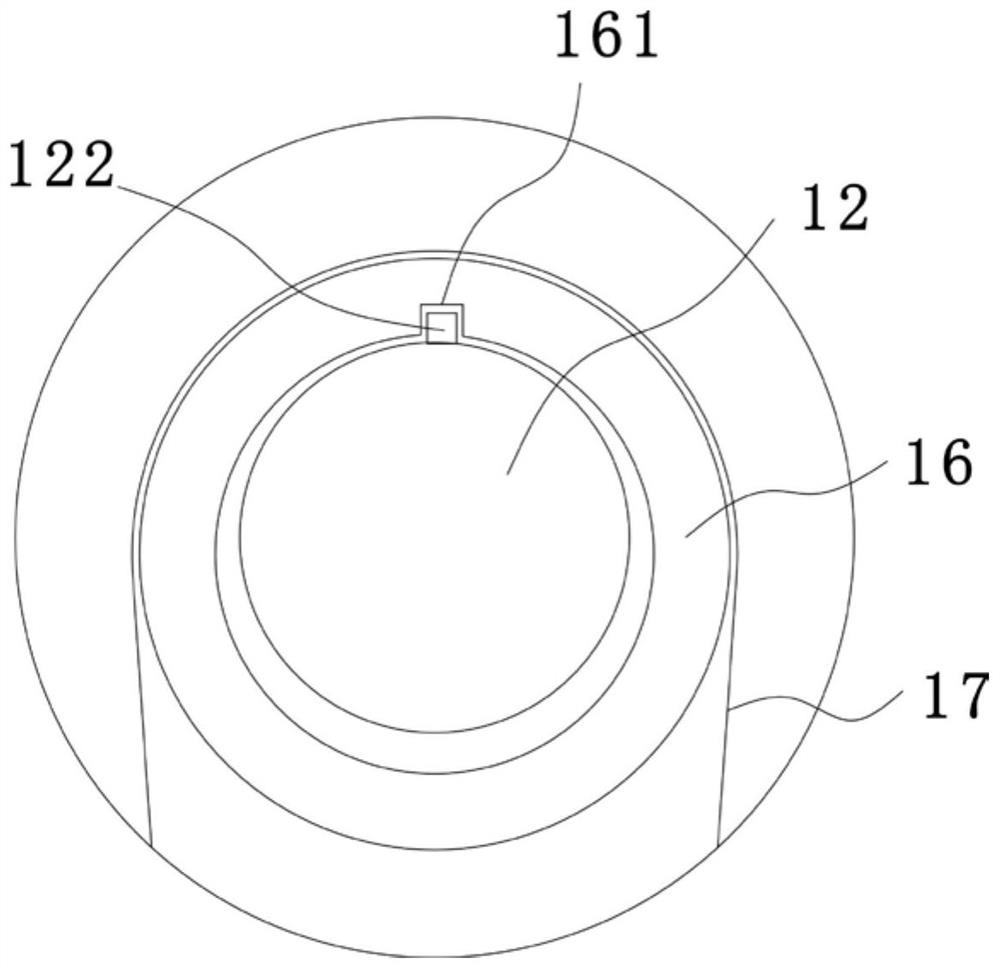

[0036] A glass fiber reinforced plastic pipe production process, comprising the following steps: a) preparation of a glass fiber reinforced plastic pipe inner lining layer: spraying wear-resistant gel coat on the surface of a glass fiber reinforced plastic core mold; b) winding process: using a glass fiber reinforced plastic pipe winding equipment to infiltrate the unsaturated polyester resin The glass fiber is reciprocally wound on the inner lining layer; c) Curing process: after winding, the pipeline is heated, the heating interval is 60-80 degrees Celsius, and the heating time is 20-30 minutes; d) Preparation of outer protective layer: outside the pipeline Apply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com