Wheel lifting suspension system based on intelligent AGV lifting perforating robot

A suspension system and robot technology, which is applied in the directions of motor vehicles, suspensions, elastic suspensions, etc., to achieve the effect of ensuring safety, compact structure and good buffering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

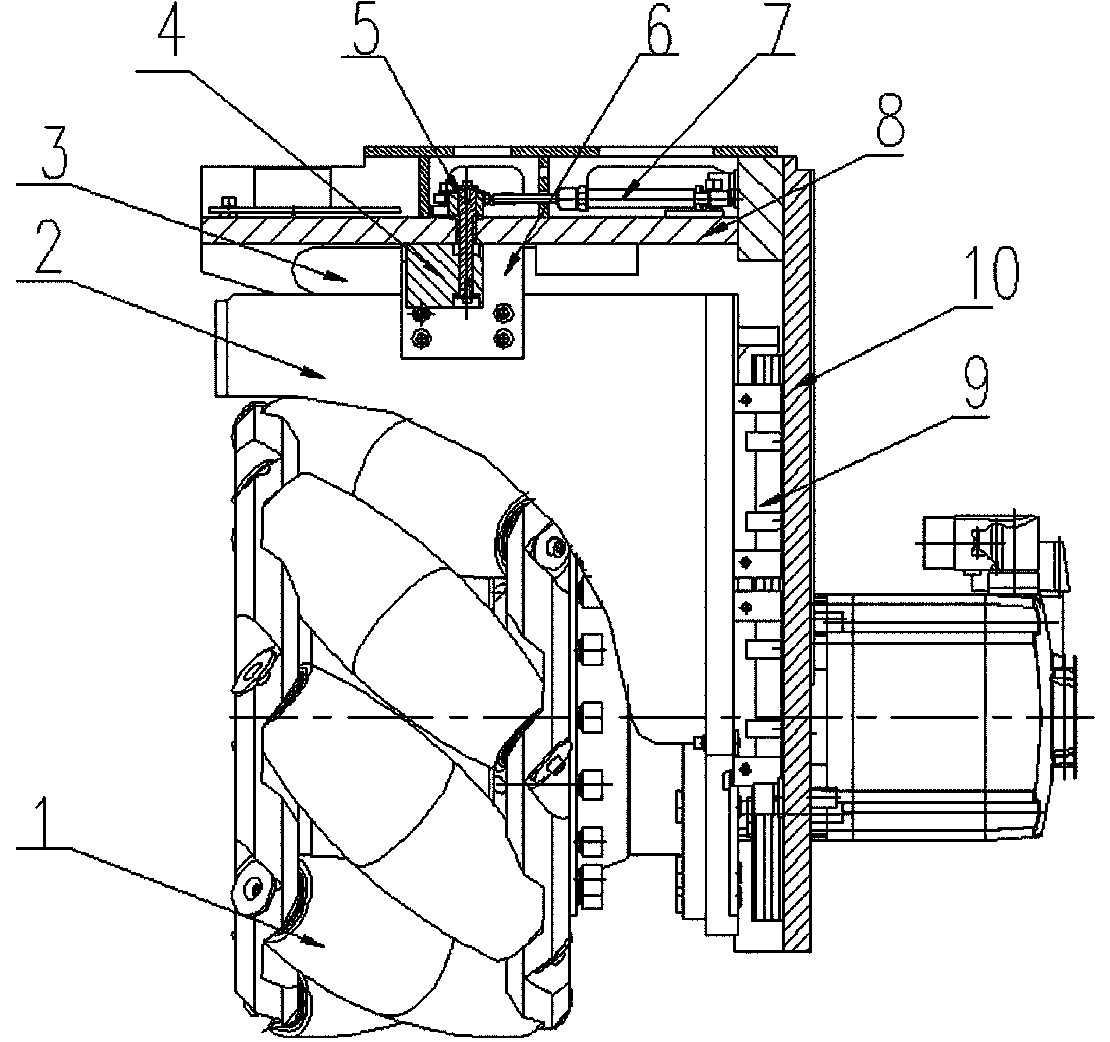

[0009] The structure of the wheel lifting suspension system based on the intelligent AGV lifting hole-making robot of the present invention is as follows: figure 1 As shown, it includes Mecanum wheel 1, mobile bracket 2, air spring 3, rotary block 4, rotating shaft 5, limit block 6, cylinder 7, upper fixed bracket 8, linear guide rail 9, lower fixed bracket 10; mobile bracket 2 It is connected with the upper fixed bracket 8 through the air spring 3, and the air spring 3 is connected with the pneumatic components, and the air spring 3 is inflated and deflated through pneumatic control; the rotary block 4 is connected with the cylinder 7 through the rotating shaft 5, and the limit block 6 is installed on the mobile On the support 2, the mobile support 2 is installed on the lower fixed support 10 through the linear guide rail 9.

[0010] When inflated, the mobile support 2 increases with the stroke of the air spring 3, so that the mobile support 2 moves along the linear guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com