A control method and control system for an extended-range vehicle power battery

A technology of power battery and control method, applied in the field of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

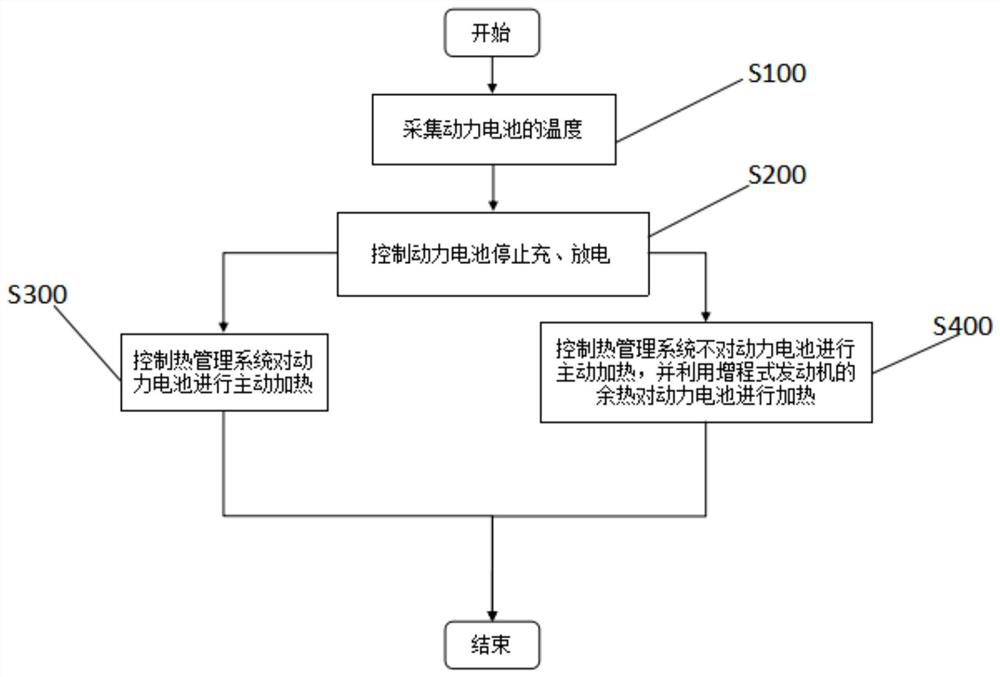

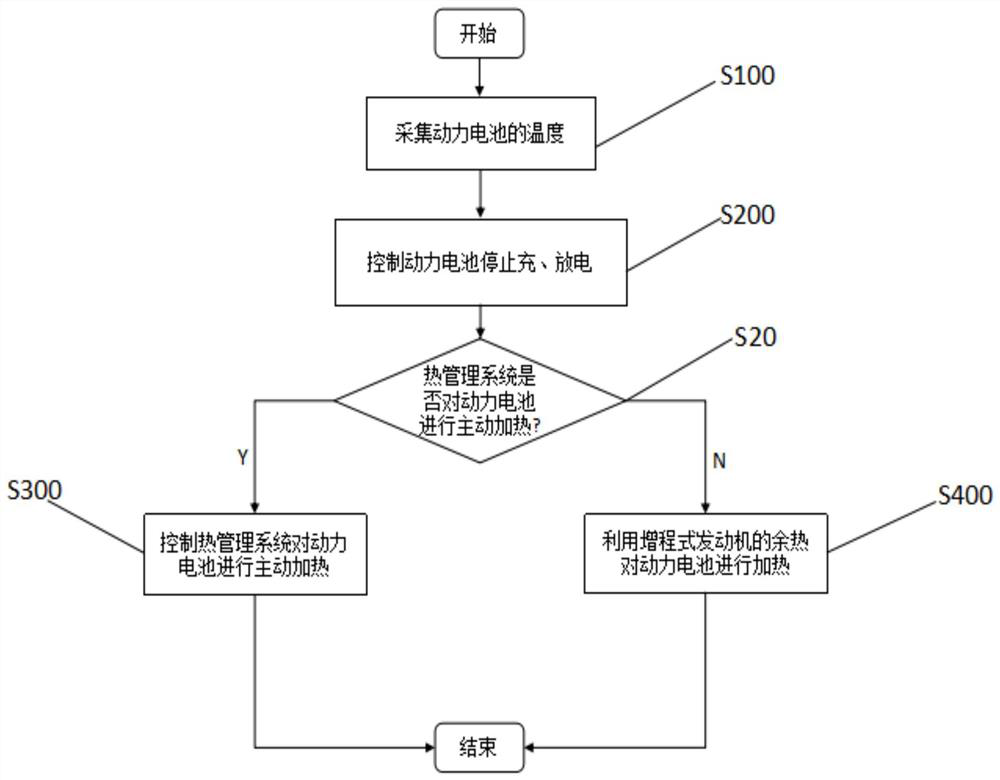

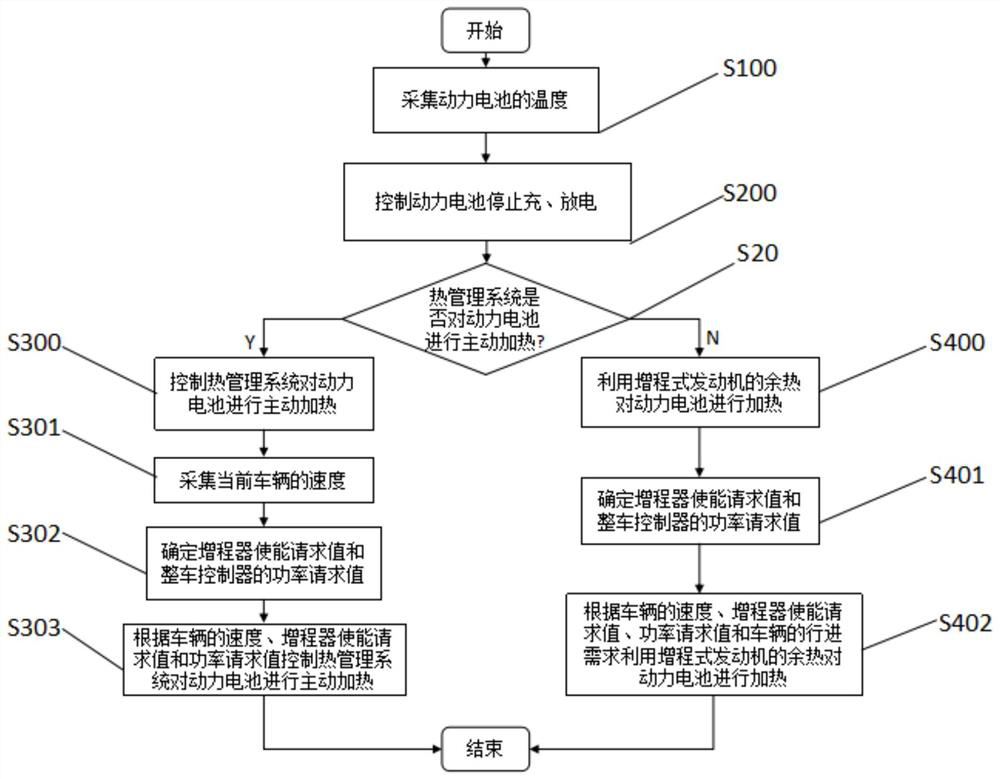

[0061] figure 1 It is a schematic flowchart of a control method for a power battery of a range-extended vehicle according to an embodiment of the present invention, which is used to control the heat management system of the vehicle or the waste heat of the range-extended engine to heat the power battery. The control method can be include:

[0062] S100. Collect the temperature of the power battery;

[0063] S200. Control the power battery to stop charging and discharging according to the temperature of the power battery being lower than a preset temperature value;

[0064] S300. Control the thermal management system to actively heat the power battery; or

[0065] S400. Control the thermal management system not to actively heat the power battery, and use the waste heat of the range-extended engine to heat the power battery.

[0066] Since the control method of the present invention controls the power battery to stop charging and discharging after the collected power battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com