Airflow preheating assembly applied to separation analysis instrument and application

A technology of separation analysis and airflow, which is applied to the parts of particle separator tubes, electrical components, particle separation tubes, etc., which can solve the problems of too simple airflow channels and low heat conduction efficiency of heating devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

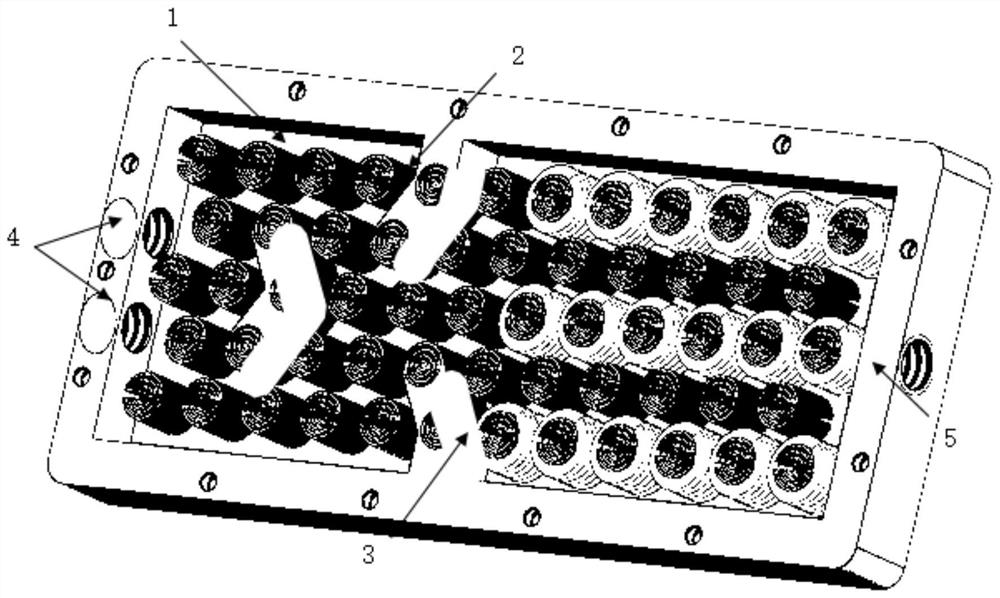

[0046] The columnar body in the airflow preheating component has both an axial contact area and a lateral diffusion area, and the cooling fins wrapped around it have the function of increasing the contact area and improving the heat conduction efficiency. Use thermal conductive silicone grease (thermal conductivity greater than 11W / (m.k)) on one side of the heating plate to fully contact the groove wall at the bottom of the cavity to remove excess air. Match the two threaded holes of [air inlet] with two quick-change joints (metal) of M3 / 5 / 6 specifications, lead out two PTFE hoses, and connect them with the gas outlet of the flow controllable gas generating device. The PTFE hose is connected by a Y-type 3-way quick-change adapter; match a threaded hole of the [air outlet] with a M3 / 5 / 6 quick-change joint (metal) to lead out a PTFE hose .

[0047] Set the heating temperature of the heating plate to 50°C, use a thermometer to measure the temperature of the airflow at the air in...

Embodiment 2

[0049] The columnar body in the airflow preheating component has both an axial contact area and a lateral diffusion area, and the cooling fins wrapped around it have the function of increasing the contact area and improving the heat conduction efficiency. Use thermal conductive silicone grease (thermal conductivity greater than 11W / (m.k)) on one side of the heating plate to fully contact the groove wall at the bottom of the cavity to remove excess air. Match the two threaded holes of [air inlet] with two quick-change joints (metal) of M3 / 5 / 6 specifications, lead out two PTFE hoses, and connect them with the gas outlet of the flow controllable gas generating device. The PTFE hose is connected by a Y-type 3-way quick-change adapter; match a threaded hole of the [air outlet] with a M3 / 5 / 6 quick-change joint (metal) to lead out a PTFE hose .

[0050] Set the heating temperature of the heating plate to 70°C, and use a thermometer to measure the airflow temperature at the outlet to...

Embodiment 3

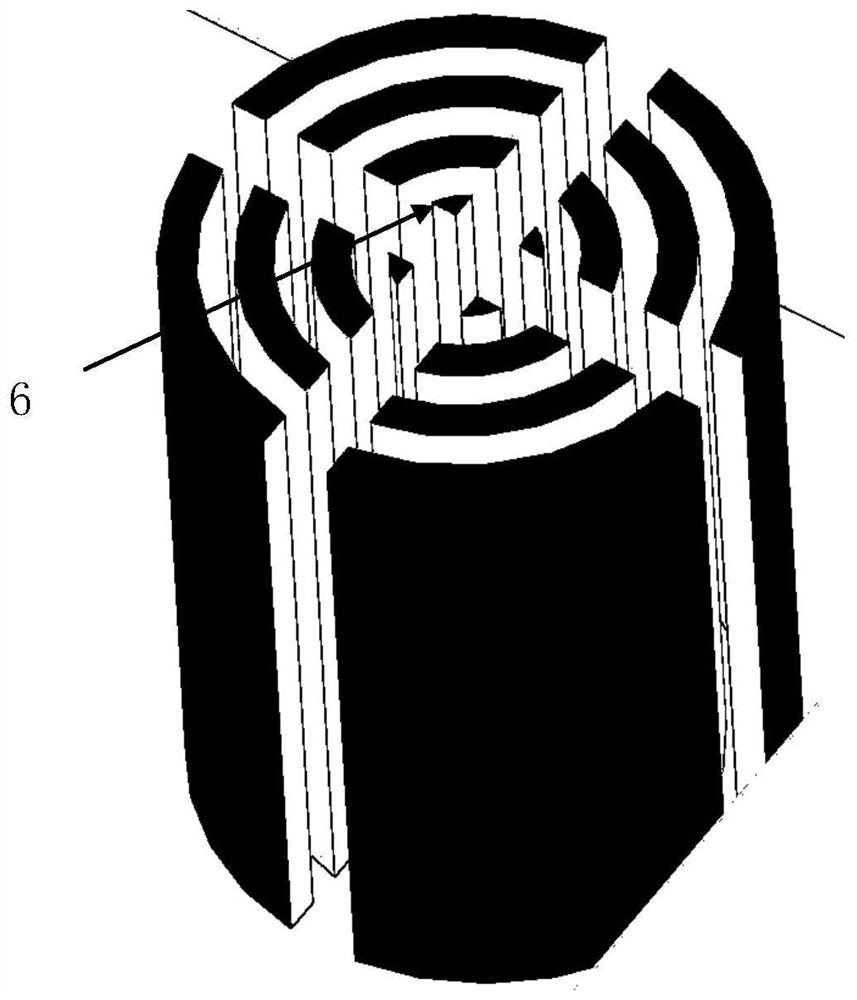

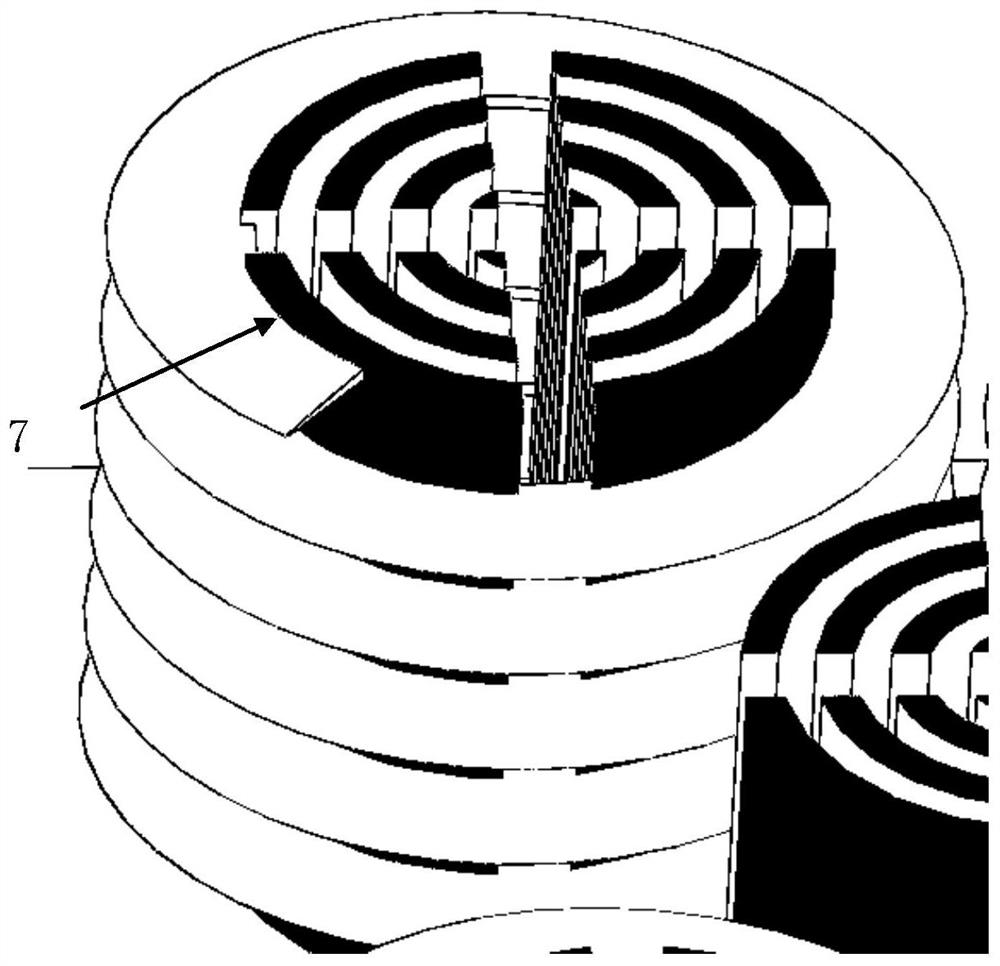

[0054] The upper and lower ends of each column in the airflow preheating assembly are provided with three ring-shaped through-holes that pass through in sequence, and two intersecting strip-shaped through-holes are opened between the upper and lower ends of the column, so that each column The body is composed of 4 gaps, 4 ring columns with diameters of 0.5mm, 1.5mm, 2.5mm, 3.5mm and a height of 5mm, and the wall thickness of the ring is 0.25mm, and the gap width is 0.2-0.3mm . The horizontal distance between adjacent columnar bodies is 6 mm, and the vertical distance is 5 mm. The heat sink is attached to the side wall of the columnar body, the pitch of the heat sink is 0.8-1 mm, the number of turns of the heat sink is 5-6 turns, and the starting angle is 50-90 degrees. Match the two threaded holes of [air inlet] with two quick-change joints (metal) of M3 / 5 / 6 specifications, lead out two PTFE hoses, and connect them with the gas outlet of the flow controllable gas generating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com