Sintering method of glass brick

A glass brick and glass technology, applied in coating and other directions, can solve problems such as breakage, increase the difficulty of operator operation, fading, etc., to reduce losses and labor costs, provide enterprises with competitive advantages, and reduce defective rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

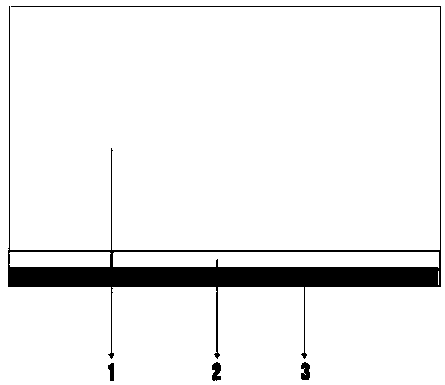

[0010] In order to understand the invention more easily, the practical implementation of the invention will be specifically described below with specific examples. Such as figure 1 As shown, the firing method of a glass brick in the present invention is as follows: mainly comprising a glass body 1, fusing the color material layer 2 on the glass body 1, printing a white sealing layer 3 on the color material layer 2, and printing the white The glass body 1 after the sealing layer 3 is then fired at a high temperature, and it is characterized in that: the step of the high-temperature firing is first firing the front side of the glass body 1 printed with the white sealing layer 3 facing upwards, and then firing The front side of the glass body 1 printed with the white sealing layer 3 is fired for the second time. Preferably: the temperature of the primary fired glass body 1 is 580-750 degrees.

[0011] Preferably: the temperature of the secondary fired glass body 1) is 770-850 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com