Polyethylene and preparation method thereof

A polyethylene and dissolving device technology, applied in the field of polyethylene processing, can solve the problems of health hazards and poor high temperature resistance of polyethylene, and achieve the effects of avoiding hazards, enhancing high temperature resistance and reducing investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A polyethylene, comprising the following components in parts by weight: 20 parts of polyethylene, 10 parts of epoxy resin, 8 parts of reinforcing fiber, 1 part of thickener, 1 part of heat insulating agent, and 1 part of toughening agent; The reinforcing fiber is composed of the following materials by weight: 8 parts of glass fiber, 3 parts of polyester fiber, 2 parts of carbon fiber, and 3 parts of phenolic resin; the thickener is gelatin powder, and the heat insulating agent is stearic acid. The toughening agent is polyvinyl acetal.

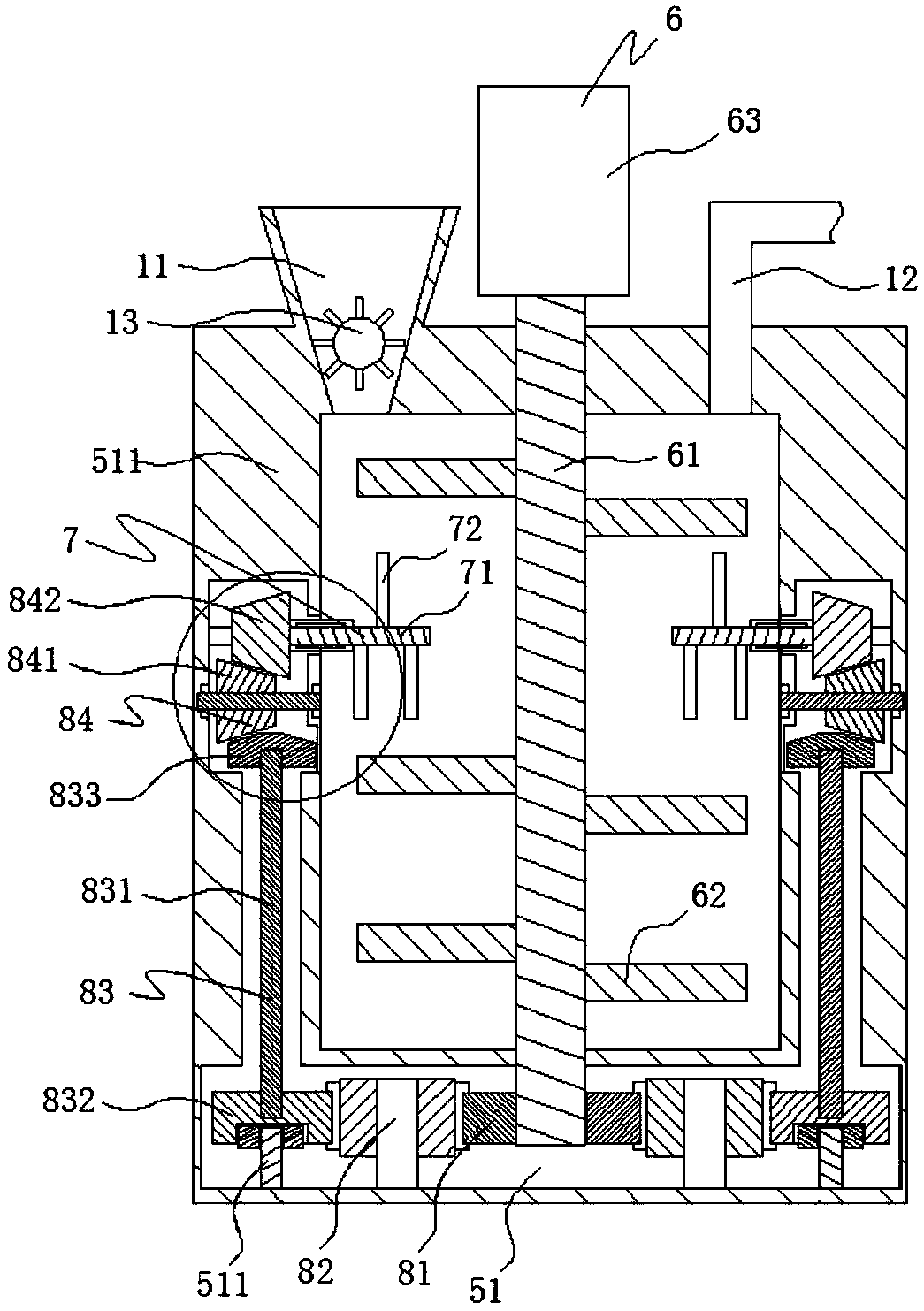

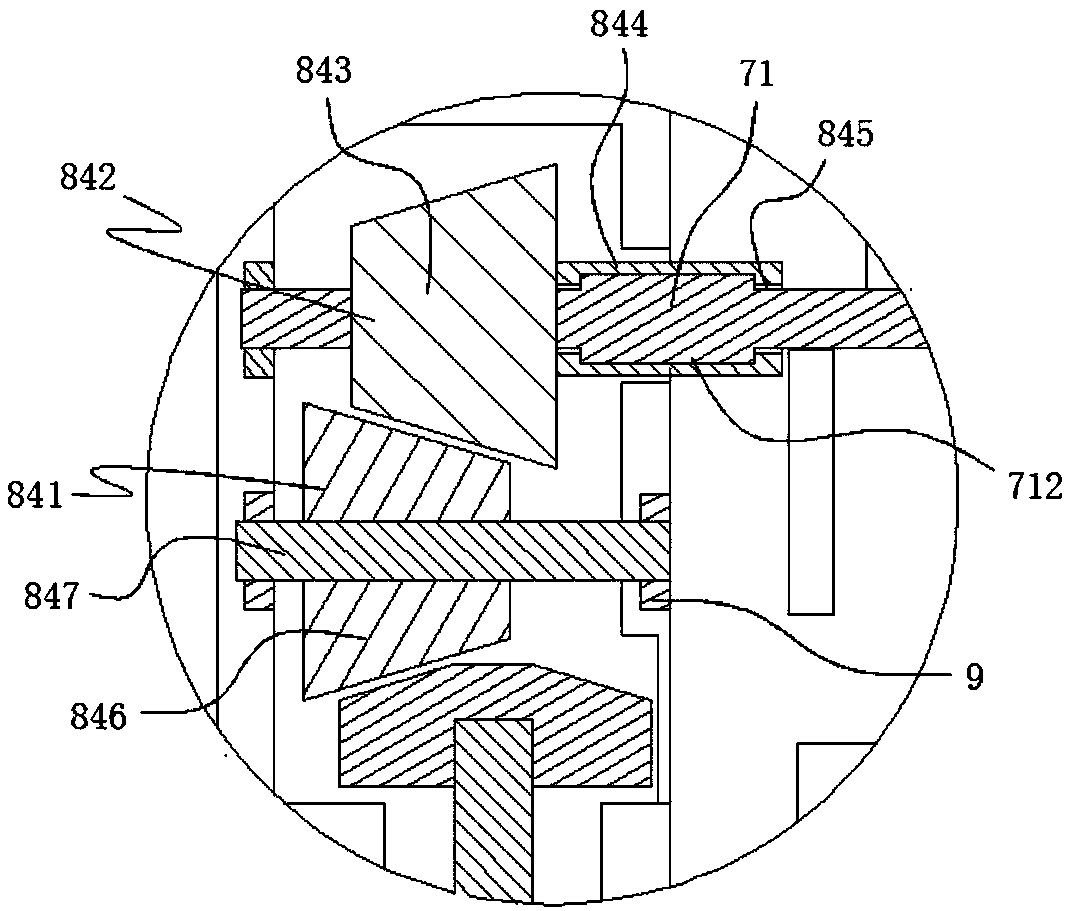

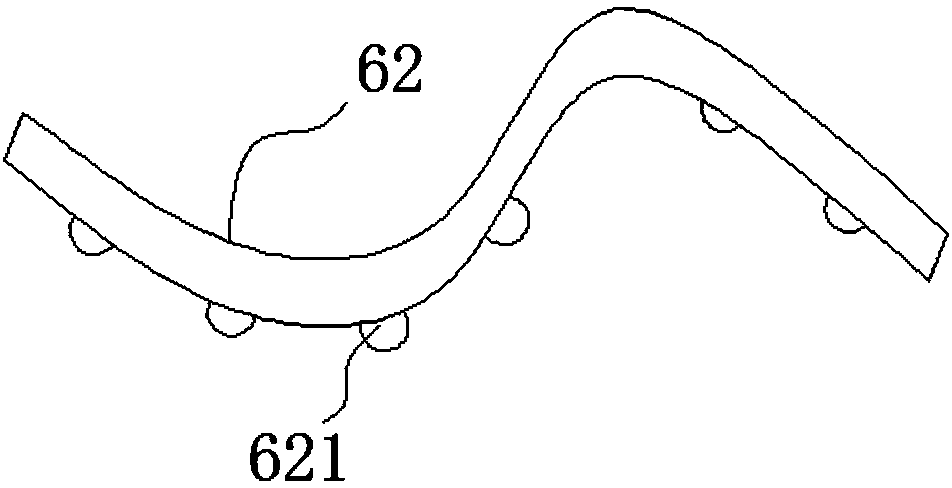

[0030] A method for preparing polyethylene, comprising the following steps: (1) taking polyethylene waste and crushing it through crushing equipment to obtain polyethylene fragments; (2) putting an organic solvent into a dissolving device, and then putting polyethylene fragments into the dissolving device, The dissolving device is started to stir the organic solvent and polyethylene fragments, so that the polyethylene fragments are disso...

Embodiment 2

[0038] A polyethylene comprising the following components in parts by weight: 30 parts of polyethylene, 20 parts of epoxy resin, 12 parts of reinforcing fiber, 2 parts of thickener, 2 parts of heat insulating agent, and 2 parts of toughening agent; The reinforcing fiber is composed of the following materials by weight: 10 parts of glass fiber, 5 parts of polyester fiber, 3 parts of carbon fiber, and 5 parts of phenolic resin; the thickener is gelatin powder, and the heat insulating agent is stearic acid. The toughening agent is polyvinyl acetal.

[0039] A method for preparing polyethylene, comprising the following steps: (1) taking polyethylene waste and crushing it through crushing equipment to obtain polyethylene fragments; (2) putting an organic solvent into a dissolving device, and then putting polyethylene fragments into the dissolving device, The dissolving device is started to stir the organic solvent and polyethylene fragments, so that the polyethylene fragments are d...

Embodiment 3

[0042] A polyethylene, comprising the following components in parts by weight: 30 parts of polyethylene, 20 parts of epoxy resin, 12 parts of reinforcing fiber, 1 part of thickener, 1 part of heat insulating agent, and 1 part of toughening agent; The reinforcing fiber is composed of the following materials by weight: 8 parts of glass fiber, 3 parts of polyester fiber, 3 parts of carbon fiber, and 5 parts of phenolic resin; the thickener is gelatin powder, and the heat insulating agent is stearic acid. The toughening agent is polyvinyl acetal.

[0043] A method for preparing polyethylene, comprising the following steps: (1) taking polyethylene waste and crushing it through crushing equipment to obtain polyethylene fragments; (2) putting an organic solvent into a dissolving device, and then putting polyethylene fragments into the dissolving device, The dissolving device starts to stir the organic solvent and polyethylene fragments, so that the polyethylene fragments are dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com