Polymer matrix composite material containing filler particle three-dimensional network and preparation method thereof

A technology of filler particles and three-dimensional network, which is applied in the field of polymer-based composite materials and its preparation, can solve the problems of insufficient performance improvement of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

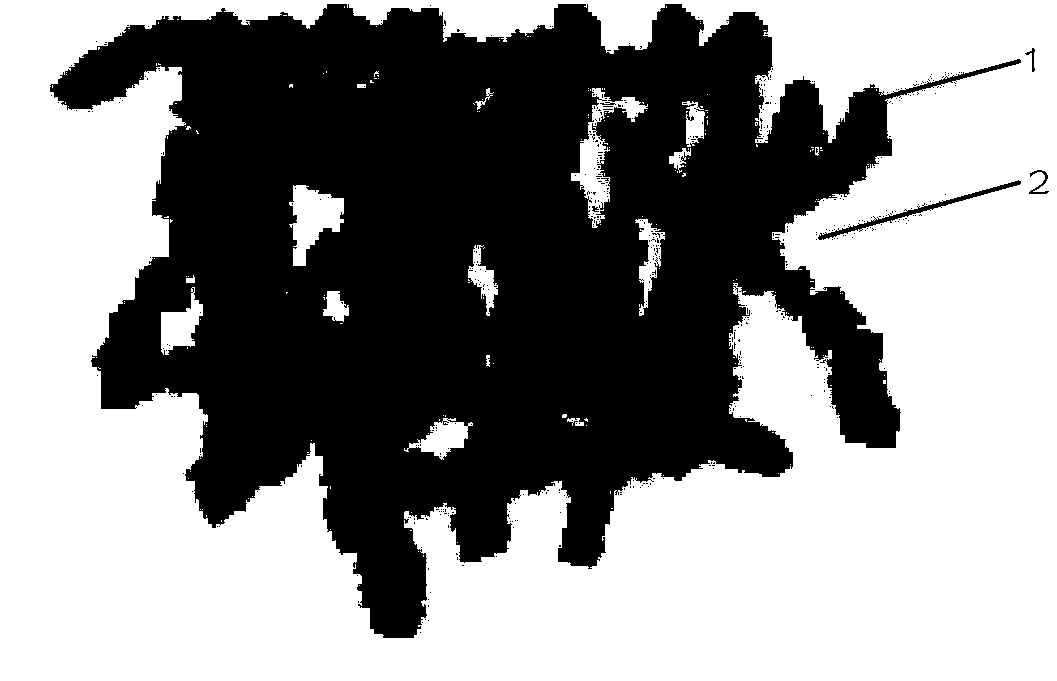

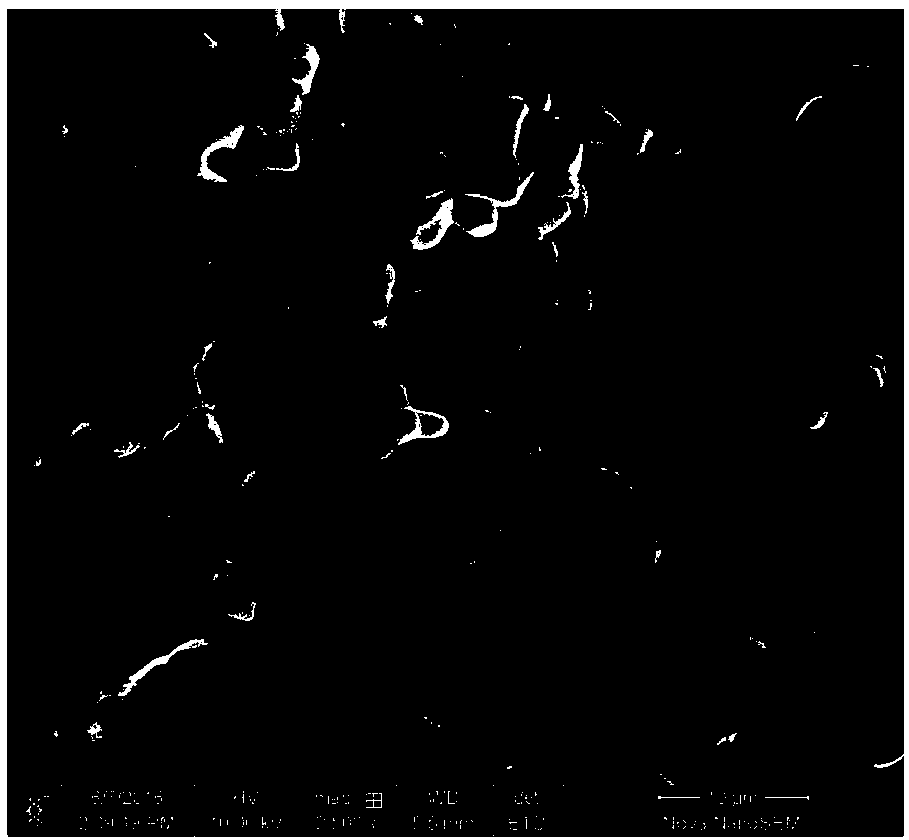

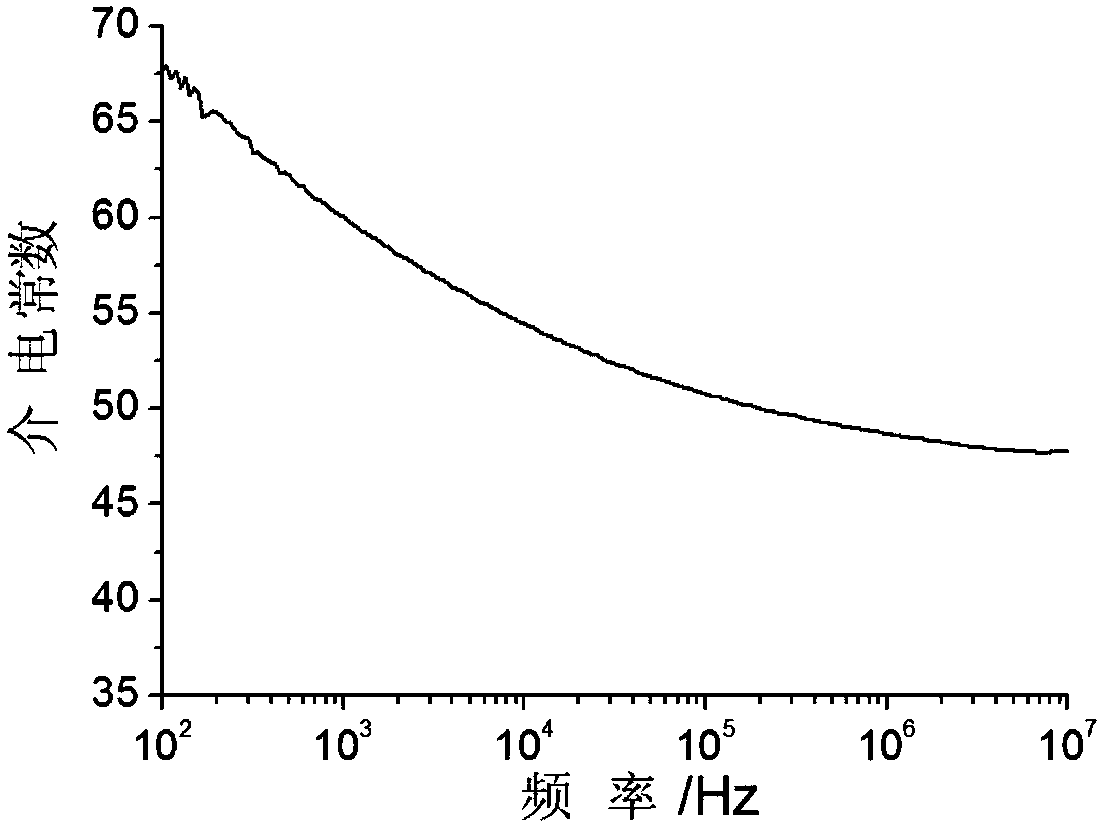

[0095] A polymer-based composite material comprising a three-dimensional network of filler particles, the polymer-based composite material comprising a barium titanate three-dimensional network composed of barium titanate filler particles, and rings filled in the voids of the barium titanate three-dimensional network oxygen resin.

[0096] Preparation:

[0097] (1) 15g of barium titanate filler particles with a particle size of 100nm were added to 60ml of cellulose aqueous solution with a concentration of 1wt% to obtain a dispersion;

[0098] (2) ball mill the dispersion at a speed of 400 rpm for 24 hours, then put the ball milled product into a mold, and freeze-dry at -40°C for 48 hours to obtain a three-dimensional network precursor;

[0099] (3) Treat the three-dimensional network precursor at a high temperature of 1000°C for 10 hours, remove the cellulose in the three-dimensional network precursor, and obtain a barium titanate three-dimensional network composed of barium ...

Embodiment 2

[0106] A polymer-based composite material comprising a three-dimensional network of filler particles, the polymer-based composite material comprising a barium titanate three-dimensional network composed of barium titanate filler particles, and rings filled in the voids of the barium titanate three-dimensional network oxygen resin.

[0107] Preparation:

[0108] (1) adding 30 g of barium titanate filler particles with a particle size of 100 nm into 60 ml of cellulose aqueous solution with a concentration of 1 wt % to obtain a dispersion;

[0109] (2) Ball mill the dispersion at a speed of 500 rpm for 18 hours, then put the ball milled product into a mold, and freeze-dry at -40°C for 48 hours to obtain a three-dimensional network precursor;

[0110] (3) Treat the three-dimensional network precursor at a high temperature of 1000°C for 10 hours, remove the cellulose in the three-dimensional network precursor, and obtain a barium titanate three-dimensional network composed of bari...

Embodiment 3

[0116] A polymer-based composite material comprising a three-dimensional network of filler particles, the polymer-based composite material comprising a barium titanate three-dimensional network composed of barium titanate filler particles, and rings filled in the voids of the barium titanate three-dimensional network oxygen resin.

[0117] Preparation:

[0118] (1) adding 60 g of barium titanate filler particles with a particle size of 100 nm into 60 ml of cellulose aqueous solution with a concentration of 1 wt % to obtain a dispersion;

[0119] (2) Ball mill the dispersion at a speed of 300 rpm for 18 hours, then put the ball milled product into a mold, and freeze-dry at -40°C for 48 hours to obtain a three-dimensional network precursor;

[0120] (3) Treat the three-dimensional network precursor at a high temperature of 1000°C for 10 hours, remove the cellulose in the three-dimensional network precursor, and obtain a barium titanate three-dimensional network composed of bari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com