Detergent putting device, washing machine with device and control method

A technology of detergent feeding and washing device, applied in the control device of washing machine, washing device, other washing machines, etc., can solve the problems of insufficient circular spraying, secondary pollution, insufficient dissolution of detergent, etc. The effect of reducing pollution and improving the quality of washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

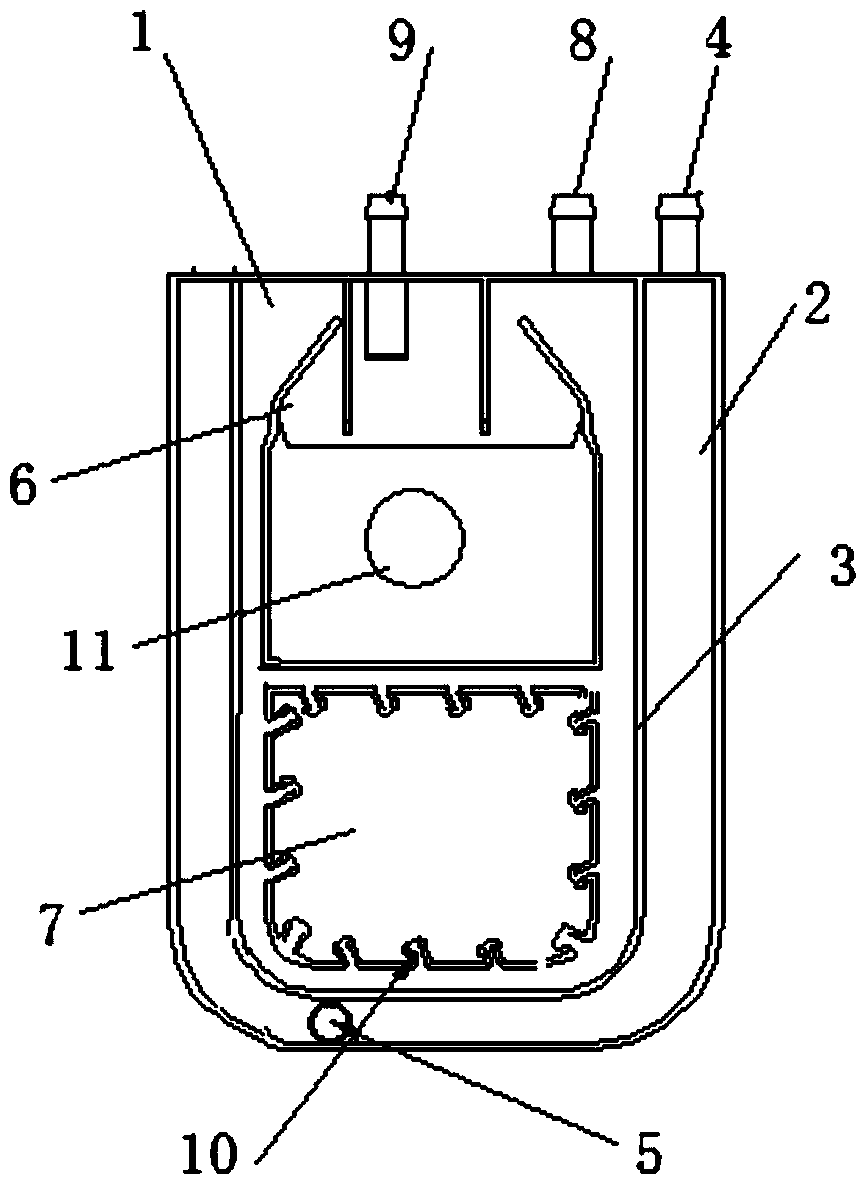

[0047] This embodiment provides a detergent delivery device, such as figure 1 shown. It includes a first chamber 1 for accommodating laundry treatment agent. Tap water passes through the first chamber 1 to flush the laundry treatment agent into the outer drum of the washing machine. It also includes a second chamber 2 isolated from the first chamber 1. Tap water passes through the second chamber. The second chamber 2 is directly injected into the outer tub of the washing machine.

[0048]The laundry treatment agent may include detergent, washing powder, disinfectant, softener, bleach and other articles for treating clothes.

[0049] The second chamber 2 does not inject any laundry treatment agent.

[0050] Further, the delivery device includes a box body with an accommodating chamber inside, and an isolation baffle 3 is arranged in the box body, and the isolation baffle 3 isolates the accommodating chamber of the box body into the first chamber 1 and the first chamber 1. Se...

Embodiment 2

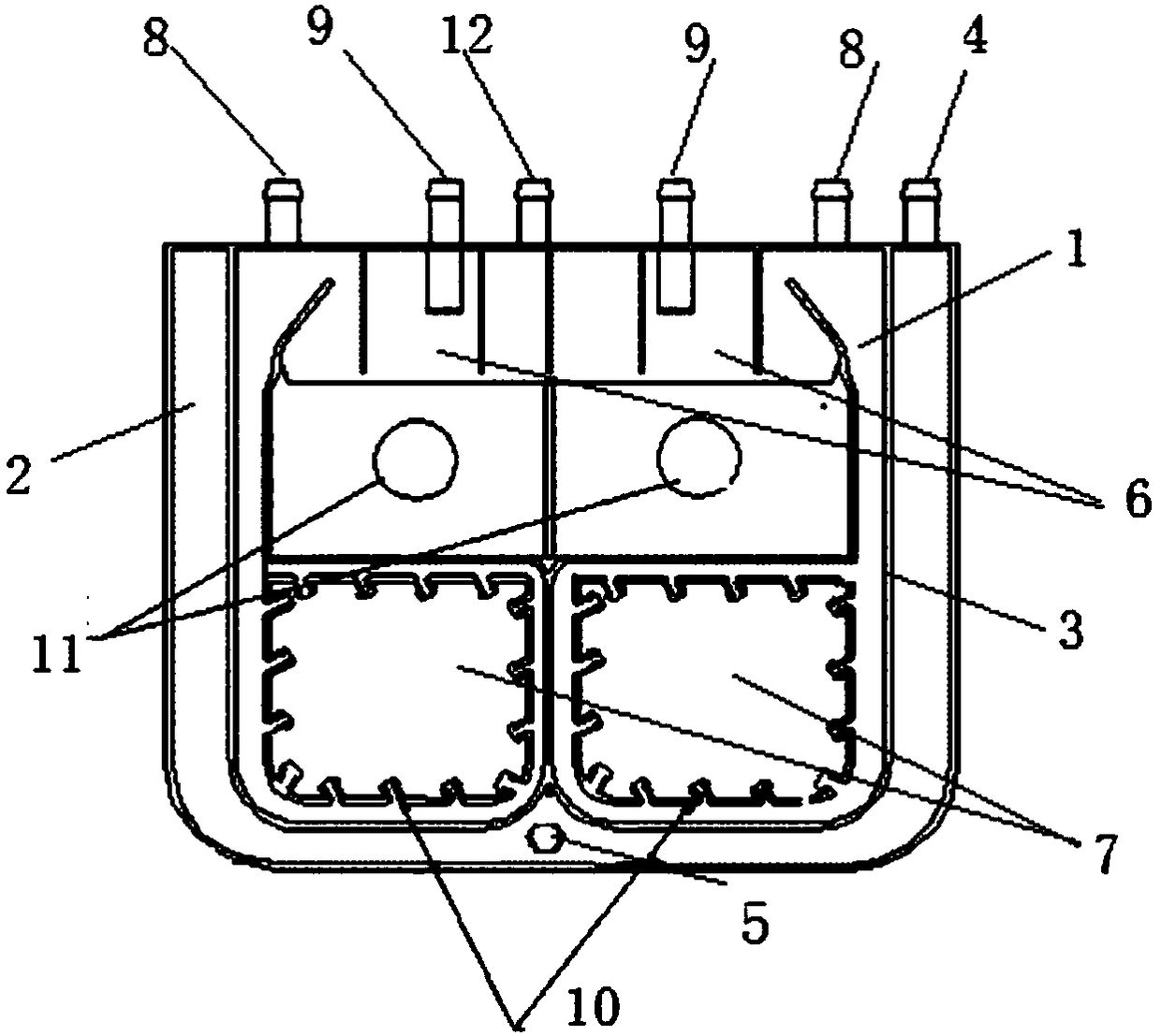

[0070] This embodiment provides a detergent dispensing device. The dispensing device includes a box body with an accommodating chamber inside, and an isolation baffle 3 is arranged in the box body, and the isolation baffle 3 separates the accommodating chamber of the box body The chamber isolation is divided into a plurality of first chambers 1 and second chambers 2 isolated from the first chambers 1, the first chambers 1 are isolated from each other, the first chambers 1 are isolated from each other, and the first chambers 1 and the second chamber 2 are isolated;

[0071] Further, multiple first chambers 1 correspond to the same second chamber 2, and the second chamber 2 is provided with a separate water inlet and a separate water outlet;

[0072] Further, in this embodiment, there are two first chambers 1, one second chamber 2, and the second chamber 2 is isolated from the two first chambers 1;

[0073] The box body is provided with a separate water inlet 4 and a separate w...

Embodiment 3

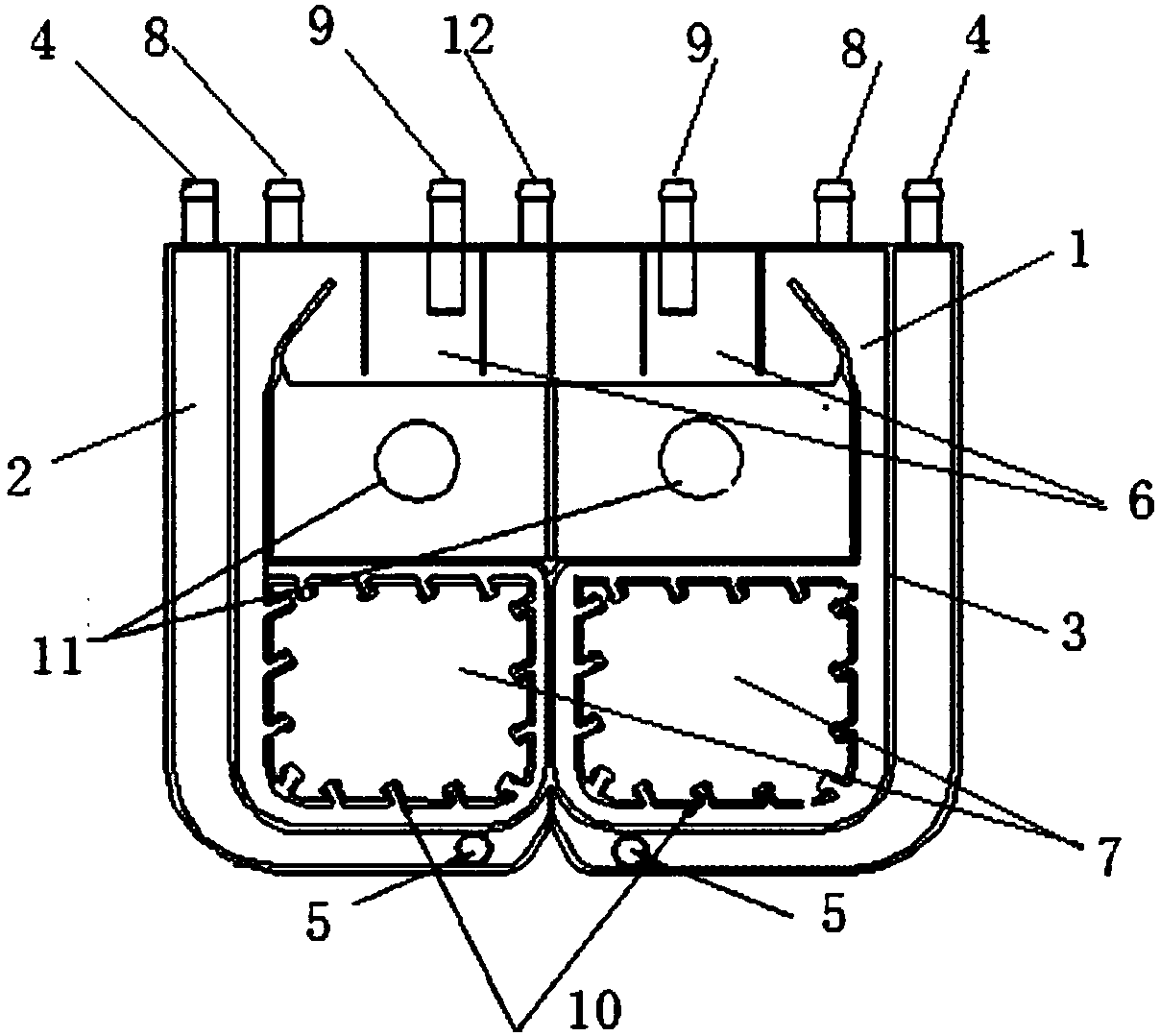

[0081] This embodiment provides a detergent dispensing device. The dispensing device includes a box body with an accommodating chamber inside, and an isolation baffle 3 is arranged in the box body, and the isolation baffle 3 separates the accommodating chamber of the box body The chamber isolation is divided into a plurality of first chambers 1 and a plurality of second chambers 2 isolated from the first chambers 1, the first chambers 1 are isolated from each other, and the first chambers 1 and the second chambers 2 are isolated from each other. Interval isolation settings;

[0082] Further, each of the first chambers 1 is provided with a corresponding second chamber 2, and each second chamber 2 has a separate water inlet 4 and a separate water outlet 5 respectively.

[0083] The first chamber 1 is used to inject laundry treatment agent, and the second chamber 2 does not inject laundry treatment agent.

[0084] During rinsing, the tap water before the last rinsing enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com